The United Kingdom’s Largest Manufacturer of Nickel Alloys, Profile Wire, Spring Wire, Round Wire and more.

Have a Question? Reach Out to Our UK Team Today at sales@centralwire.co.uk

For more than 60 years, Central Wire Industries has drawn on innovation to manufacture custom profile wires for a range of applications. From wedge wire for screens to fully custom shaped wire used in aerospace engines, the specialty profile wire is designed to exceed your material requirements. Read on to find out about CWI UK manufacturing, including: premium nickel alloys and more! Central Wire Industries UK is where your ideas take shape!

Our global leadership doesn’t end with Profiled Wire. We manufacture Round Wire & Spring Wire in stainless steel, nickel, and red metal alloys from .0635 mm and larger with precise tolerances, and tensile strengths from full soft to spring temper. We support the oil and gas industry with our GD – Supa Slickline products shipped around the globe directly from our stock – stock located in three continents, Europe, Middle East, & the United States. Our CWI Generation4™ Welding Wire is a revolutionarily product produced to the highest quality standards for use in all industrial welding applications.

Ready to learn more? Browse CWI UK Manufacturing: Nickel Alloys | Profile Wire and More!

Profiled/Shaped Wire

Manufacturing Standard & Non-Standard Shapes

CWI UK is a leading manufacturer of Profile Wire, Wedge Wire, and Custom Shaped Wire in a wide range of Stainless Steels / Super Austenitic / Duplex / Super Duplex / Nickel Alloys and other materials; all available in a variety of tempers, finishes, and packages. Our in-house tooling allows us to assist in creating complex designs to meet your requirements.

GD™ - SUPA® Slickline Wireline

Manufacturing Slicklines for Oil & Gas

The CWI family of GD™ – SUPA® slickline wirelines are recognized around the world for their superior engineering, quality, and reliability, Our slicklines are manufactured in the United States, Canada, and in the United Kingdom at our CWI UK Rotherham facility. These slicklines are manufactured from alloys designed to survive in the harsh and corrosive conditions that exist in oil, gas, and geothermal well environments.

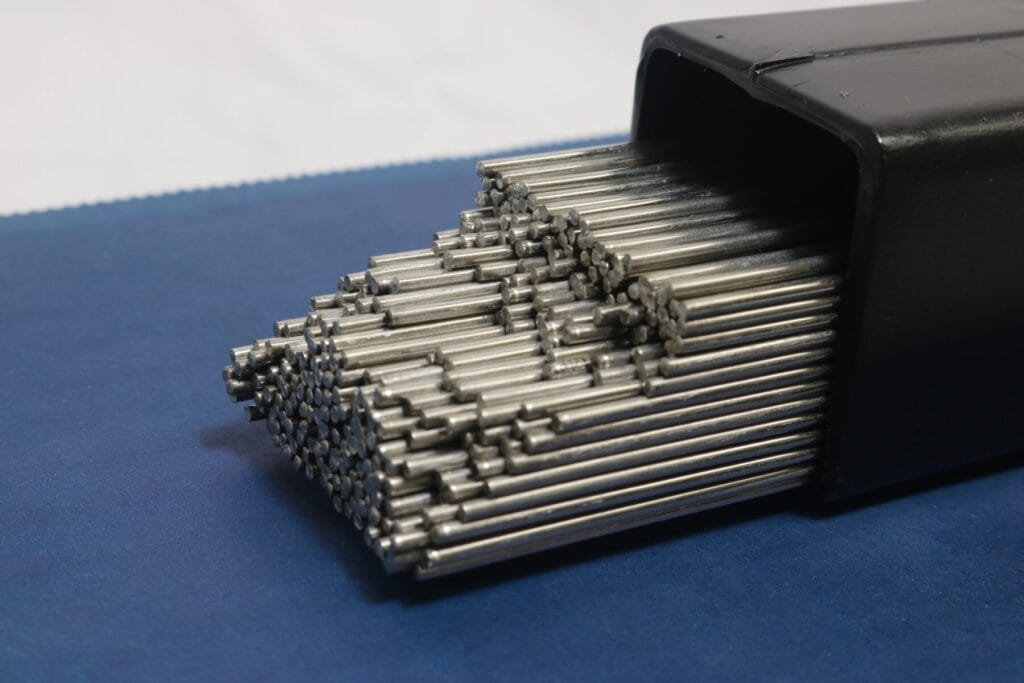

Welding Wire

CWI Generation4™: MIG, TIG, & SAW Welds

Our evolutionary CWI Generation4™ – specialty alloy welding products are manufactured with the highest quality raw materials, including; stainless, nickel, specialty nickel-chrome, cobalt and copper. Whether you’re a fabricator or a wholesaler, our welding wire is available to suit your project needs. MIG, TIG, and SAW weld types are all available, domestically manufactured in our ISO 9001:2015 certified facility.

Specialty Stainless and Nickel Alloys

Premium Spring WIre Manufacturing, including x750, Mp35N® & Beyond

At CWI UK, our diverse range of high-performance specialty alloys, includes:

- Inconel® X750

- Withstands high temperatures

- Resistant to stress corrosion cracking

- MP35N®

- Resists corrosion in hydrogen sulfide

- Nickel Alloys

- 400 / 600 / 601 / 625 / 825 / 718 / C4 / C22 / C276 & More

- Duplex

- 1.4462 / Super Duplex 1.4410 / 1.4507 / 1.4501

- 17/7 PH (1.4568)

- Available in sizes from 0.70mm to 18.00mm

- High Tensile Strength

- A286

- Withstands high temperatures

- High Tensile Strength

- Extensive Range of Stainless 300 & 400 Series

- Cost-effective

- Can be hardened by heat treatment

…and many more! These specialty alloys provide superior corrosion resistance, high strength, and excellent performance in extreme environments. CWI’s alloys are ideal for applications requiring durability and reliability, such as aerospace, chemical processing, and oil and gas industries. Browse an extensive list of our stainless and nickel alloys below.

Quality & Testing

ISO9001 Certification, Non Destructive Testing & More

The CWI UK facility located in Rotherham is certified to ISO 9001:2015 for the manufacture of high-quality stainless steel and nickel alloy wires, which are produced in accordance with national and international standards and customer specifications and requirements. Download our ISO certification here. Our UK plant also conducts PPAP, IMDS Entry, & 3.2 Certification, and is a member of IST.

Facility Spotlight & Video Showcase

Wire Manufacturing in Rotherham

At our UK facility, we offer custom packaging options, including coils, spools, formers, and cut lengths, and cater to unique size requirements with our specialty alloys. Our commitment to quality is reflected in our ISO 9001 certification and meticulous manufacturing processes like rod processing, wire drawing, and annealing. Our dedicated team, proud recipients of the Queen’s Award for Enterprise in 2018, ensures exceptional products and services for all your needs.

CWI UK Manufacturing: Nickel Alloys | Profile Wire and More!

Check out our video on the right of your screen, breaking down our plant capabilities, industries we serve, and quality commitments!

EXPERIENCE EXCELLENCE

Top Quality

We are trusted across the globe in mission critical applications for one reason: our commitment to quality. Our mature quality systems, including ISO 9001, AS9100, and ISO 13485 attest to the rigorous systems we have created to maintain quality.

Quick Lead Times

With 13 manufacturing facilities across the globe, we have the capacity to turn orders quickly, while maintaining the quality standards you expect. Don’t assume it can’t be done, contact us today for your delivery requirements. CWI UK Manufacturing: Nickel Alloys | Profile Wire and More! Get a quote below!

Your Specifications

Our engineering and production teams have the processes and experience to build to your specifications time and time again. Looking for something more? We can assist with that as well. Send us your designs and we will make it happen for you.