Construction Reliability and Consistency

In a labor-heavy industry like construction, employees and companies need materials that can last and perform. The construction industry relies on safety precautions and efficient work to get projects done well and on time.

Below are our product lines that cater to the industry, and some of the applications of our products to the construction industry.

Product Lines

Custom cable assemblies crafted with precision and expertise. Our aircraft, military, and commercial cable assemblies are all highly customizable, and are durable enough to withstand demanding applications.

Involves a meticulous process of extruding a plastic jacket onto aircraft cable or wire rope, to enhance durability, functionality, and improve aesthetics. More resistant to abrasion than ordinary cables and adds resilience for harsh conditions.

CWI red metals are available in a variety of high-performance alloys. Copper’s conductivity and antibacterial properties make it applicable for resistance wire, fine wire, knitted mesh and medical wire applications.

High quality fine wire produced in sizes from 0.001” up to 0.032” with custom sizes available by request. Tempers range from soft annealed to spring temper

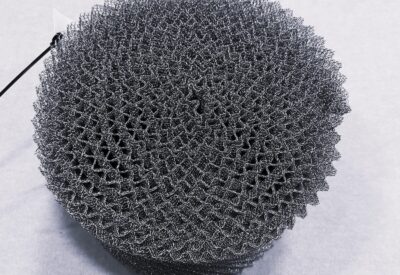

Wire filter mesh made from individual wires that are interlaced, or knitted, together. Loops are strategically woven to be able to move and stretch, with flexibility and durability to handle harsh applications.

Lashing wire alloys are used in the fabrication of pole line hardware. It is designed to withstand tension and provide long-lasting support for cables. Available in standard diameters; 0.038”, 0.045”, 0.062” and 0.065”.

One of the most important structural decisions in a building is seismic force protection. Our seismic bracing cable is easy to install, comes on convenient 250 ft spools, with high certified break strengths to help reduce damage during earthquakes.

Available in stainless, duplex, nickel, copper, brass and carbon alloys, our shape wire is custom manufactured in house to fit specific customer needs. The profile wire sizes we offer are 1.25mm² to 150mm ² CSA (Cross Sectional Area).

Our Locoloc® swaging tools are crafted at our Naples, Florida facility. Built for durability in demanding applications, our high-quality tools precisely fit cable sleeves from 1/32” to ½”.

Welding wire produced for various techniques including MIG, TIG and SAW welding. Available in stainless and nickel-based alloys.

In some of the challenging conditions of construction, our products stand above the rest.

Let’s take a look at some of the applications of our products within the construction industry.

Product Applications

Swaging & Crimping

Our variety of swaging and crimping tools can cut through cables, wire rope and metals with ease. Hand swagers offer a cheaper option while battery swagers produce efficiency and require less physical exertion.

Both tools are versatile, able to cut multiple materials as well as different sizes. Any maintenance or construction job that requires wire cutting can be done by these tools.

Welding

Any construction job involving metals may need welding repairs at some point due to wear and tear. Choosing the right welding wire and technique ensures quality repairs that will last, saving time and money.

When building a structure, a good weld ensures safety and durability that can withstand harsh conditions.

Support Cables

Many construction applications require support or safety cables for both peace of mind and better results. Our lashing wire, typically used on telephone poles to secure wires can be used on a construction site too.

In projects involving extensive cabling, lashing wire can bundle them together, avoiding tangling or becoming disorganized. It can also be used to temporarily tie materials together like lumber or scaffolding until they can be permanently installed or secured.

Earthquake Plans

One of the biggest choices when designing a building is what seismic bracing materials to use to mitigate damage risks during an earthquake. For a variety of construction jobs, our seismic bracing cable is recommended for a few reasons.

It is a very lightweight alternative to rigid pipe bracing, so it is easier to install and transport. It also comes on 250 ft spools for a large inventory that doesn’t take up a lot of space. It also has break strengths well above our normal cables, assisting in risk mitigation during an earthquake.