A product line that leverages our customization capabilities, industry expertise and our versatile raw material catalog is our Tech-Mesh™. Central Wire is able to cater to the requirements of a variety of industries due to the versatility and precision of our mesh manufacturing. We understand the difficulty of finding a quality, custom manufacturer and we take pride in meeting our customer’s exact specifications!

The extensive manufacturing process of our mesh includes seven steps which prioritize precision and customization to meet the needs of each customer’s project. Learn about the importance of each step along the way, from Raw Materials to Custom Finished Product in our detailed, step-by-step blog here!

Continue reading below to discover the strengths and strongest applications of some of the alloys we manufacture our Tech-Mesh™ with, and to learn how choosing Central Wire as your supplier means choosing quality and reliability.

Our Mesh Alloy Catalog

To handle the varying conditions of the industries that rely on our mesh, we offer many raw material options across this product line. The stainless steel, nickel and red metal alloy options that we offer each present unique advantages:

- Stainless Steel: Provides Excellent Corrosion Resistance

- ex. 300 series, Duplex, etc.

- Nickel: Combines High Strength with Good Corrosion Resistance and Durability

- ex. Alloy 20 (20cb3), Inconel® alloys, Monel® alloys, etc.

- Red Metals: Able to Withstand Rust and Other Forms of Corrosion

- ex. Copper alloys, etc.

Other Customization Options

Alongside our alloy variety, our Tech-Mesh™ can be customized based on mesh density, product geometry and more! Check out the options below!

Mesh Density

Referring to the number of wire strands per mesh loop, or the mass of material, finished part density impacts the strength, durability and performance of a mesh unit. Denser mesh will be heavier but capture and entrap more materials if that is the priority of the application, while a less dense mesh is more lightweight, flexible and allows more liquid or gas to pass through.

Product Geometry

Meeting customer’s exact specifications can include manufacturing precise product geometries. Our Demister Pad or Mist Eliminator products can be tailored to round, rectangle, ring and custom geometries to fit perfectly into different shaped tanks and vessels, offering excellent versatility while maintaining performance.

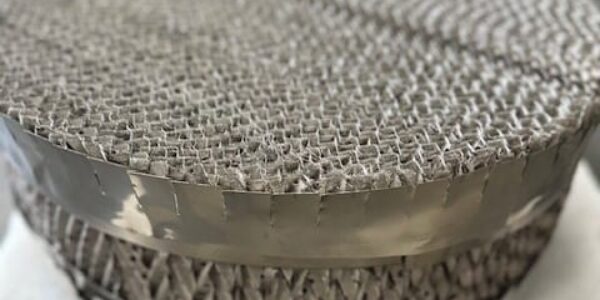

Crimped Mesh

In many variations of Tech-Mesh™ manufacturing, crimping is one of the final steps and is employed to achieve the final required mechanical properties and specifications. Crimping individual layers of a mesh system creates small pleats, which ensure the captured liquid droplets agglomerate and drain properly, to allow only dry vapor to exit the mesh.

Support Frame Construction and Attachment

The majority of Tech-Mesh™ applications will need the addition of a support frame to maintain shape, structure and stability after repeated use. These frames typically match the alloy of the mesh but can incorporate various alloys to meet a customer’s needs. Without support frames, the mesh does not have enough structural strength to preserve its shape and size.

Tech-Mesh™ Applications

Being able to customize the products in our Tech-Mesh™ line to very specific sizes and shapes, as well as various raw materials leads to very versatile industry application. From commercial Brewing and Distilling to high-production Oil and Gas plants, here are some of the specific applications of this product line:

- Gas-Liquid Separators

- Process Absorbers and Scrubbers

- Knockout Drums and Receivers

- Oil Refinery Columns

- Brewing and Distilling Vessels

- Pollution Control Equipment

- .. and more!

If you’re not seeing your required application in the list, feel free to contact our knowledgeable sales team at sales@centralwire.com, to find out if our Tech-Mesh™ suits the needs of your next project!

Trusting in Our Custom Manufacturing

The care and precision of our manufacturing, alongside our extensive raw material catalog, positions us as leaders in mesh product manufacturing. Our Tech-Mesh™ helps to maximize separation efficiency, minimize pressure drop, and leans on a combination of flexibility and durability to ensure performance is consistent.

To invest in our knowledge and precision, and kickstart your next project with us, Request a Knitted Wire Mesh Quote with us below!