As a multi-faceted manufacturing company, the majority of our products are not sold from stock. Much of our production revolves around manufacturing to a customer’s specific needs.

Some of the industries we serve, such as Aerospace, Military and Automotive, require extremely precise parts to be used as fasteners, engine components and more. Specific machinery is required to create the right product to serve our customer base with short lead times.

Loos Precision Products

This is where Loos Precision Products comes in. Our CNC Machining and engineering capabilities allow us to offer a diverse range of precision parts to suit your needs. Our highly trained and experienced machining team sets us apart from our competitors, with the knowledge and expertise to bring any project to life.

These capabilities allow the ability to work with materials including:

- Stainless Steel

- Aluminum

- Brass

- Bronze Alloys

- Carbon Steel

- Inconel®

- Copper

- Nickel

- Exotic Metals

- Plastics

Continue reading to discover the machining capabilities we possess, and some of the specifics of our Precision Part Manufacturing.

In contrast to Turning Machines, CNC Milling Machines use rotating cutting tools and stationary workpieces. The tools move along multiple axes to create precise shapes and features.

These machines use various types of tools, including end mills and face mills to create complex geometries and maximize customization. They are capable of high precision and are versatile in their use on parts of all shapes and sizes.

The versatility and efficiency of Milling Machines promotes application in an abundance of industries, including Aerospace and Automotive where complex parts and precise geometries are often required.

Our CNC Machines

The capabilities of our Precision Part Manufacturing begin with a long list of turning, milling and cutting machinery. Our range of equipment allows us to machine parts down to exact specifications with tight tolerances as small as .001″. Here are some of the most commonly used precision machines, and some information on how they work.

CNC Turning Centers

The first of the machines being highlighted is our CNC Turning Machines. These machines use a single-point cutting tool that is controlled by computer numerical control (CNC). They are used most commonly to produce cylindrical parts, as material is removed from a rotating workpiece.

CNC Turning Machines offer high precision and can produce parts with tight tolerances. They are suitable for both short and long cylindrical parts, often being used to manufacture shafts, bolts and other rounded components.

The precision and cylindrical focus of these machines allows for application in Automotive and Aerospace industries, where rotational parts play a role in structural components and engines.

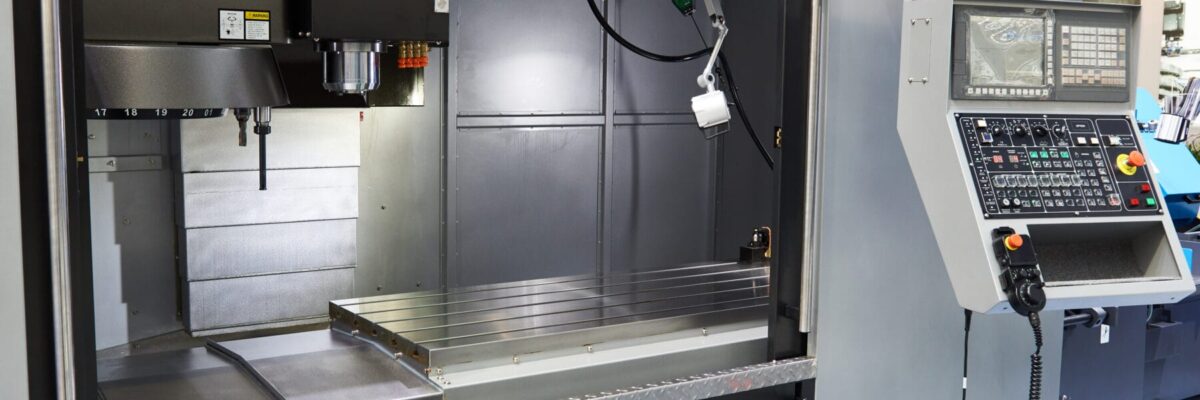

CNC Milling Centers

In contrast to Turning Machines, CNC Milling Machines use rotating cutting tools and stationary workpieces. The tools move along multiple axes to create precise shapes and features.

These machines use various types of tools, including end mills and face mills to create complex geometries and maximize customization. They are capable of high precision and are versatile in their use on parts of all shapes and sizes.

The versatility and efficiency of Milling Machines promotes application in an abundance of industries, including Aerospace and Automotive where complex parts and precise geometries are often required.

Swiss Lathe Machines

A Swiss type lathe, or Swiss screw machine, excels at conducting turning and milling operations simultaneously. They are specialized for small and complex parts which require high precision.

The tooling setup on these machines is unique, with multiple cutting tools that can work on different parts of the workpiece simultaneously. This machine type is often used on long, slender parts that are machined from bar stock.

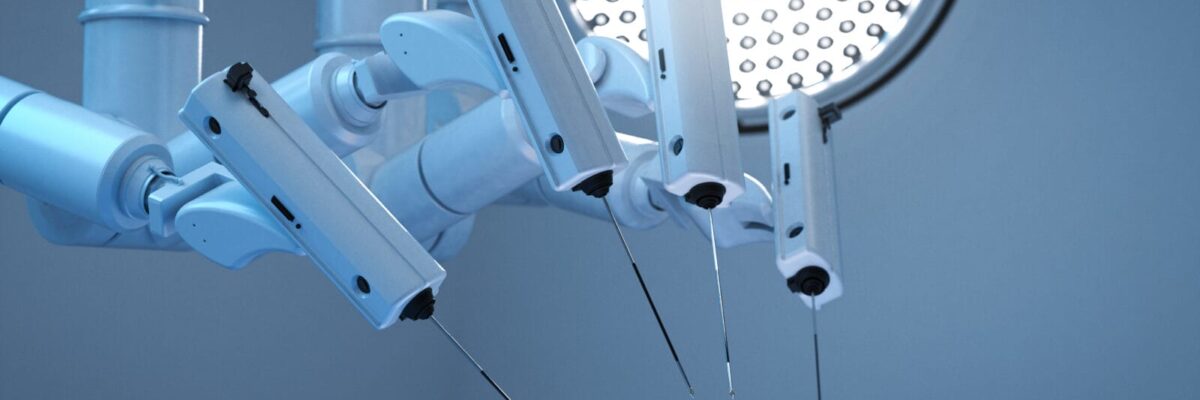

Offering high precision and repeatability, these machines are commonly used to support industries where small and intricate parts are required, such as the Medical industry.

Turnaround Times

Loos Precision Products possess just over 30 machines, and with a wide variety of CNC capabilities, we are able to help increase production and shorten lead times for our customers.

Our custom manufacturing capabilities are complex, but we are still able to turn orders into parts quickly and efficiently.

Industries Served by CNC Machinery

Our custom and precision CNC Manufacturing supports many industries, with the precision required to handle harsh and demanding conditions. The extensive list of industries and applications this product line supports includes:

Aerospace

- Engine Components (Turbine blades, housings)

- Interior Fittings (Seat frames, panels)

- Structural Components (Frames, fasteners, rudders)

Automotive

- Engine Components (Pistons, valves, cylinder heads)

- Transmission Components (Gears, shafts)

- Suspension Parts (Brackets, hubs)

Medical

- Surgical Instruments (Scalpels, forceps)

- Orthopedic Implants (Knee and hip replacements)

- Dental Prosthetics (Implants, crowns)

Military

- Aerospace Parts (Structural, fittings, engine)

Renewable Energy

- Structural Components (Turbine shafts, bearings, hubs)

- Solar Tracking (Structural framework)

Investing in our Custom Manufacturing

With our AS9100 and ISO9001:2015 certifications, and QPL/QPM Mil-Spec listings, our quality is unmatched.

Our CNC products also go through rigorous testing, such as Fluorescent Penetrant Inspection, Hardness Testing, Tensile Testing, and more. View our full testing capabilities here!

Visit our CNC Machining product page here to learn more about our capabilities and equipment.

To invest in our custom manufacturing and secure the precision product that you’re looking for, request a quote with us today!