Engineering and Design Innovations

Customization capabilities are one of our greatest strengths, with products fitting to your exact applications every time. From custom sizing and shapes to precise CNC machining, we can always manufacture the exact product you need.

Below are our product lines catering to the industry, and the applications of our products in the engineering and design industry.

Product Lines

Premium stainless steel and nickel bar stock manufactured up to 0.750” to customer specifications. Highly customizable for many end-use applications and mission critical industries.

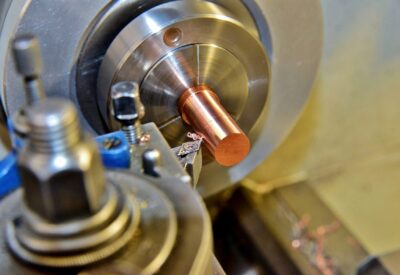

Custom CNC manufacturing can use many different alloys including stainless steel, aluminum, brass, bronze, copper and nickel. Custom parts are tested in-house to ensure quality, and precise machining produces the perfect product every time.

Cold heading wire is available in stainless, nickel, and copper base alloys. Quality raw material for use as fasteners, blind rivets, screws and bolts.

Available in stainless, duplex, nickel, copper, brass and carbon alloys, our shape wire is custom manufactured in house to fit specific customer needs. The profile wire sizes we offer are 1.25mm² to 150mm ² CSA (Cross Sectional Area).

These four product lines offer full customization in our manufacturing. Shapes and sizes can be customized to exact needs, with precise manufacturing ensuring you get exactly what you ask for.

Let’s look at the exact capabilities we have for each of these four product lines.

Product Applications

Centerless Grinding

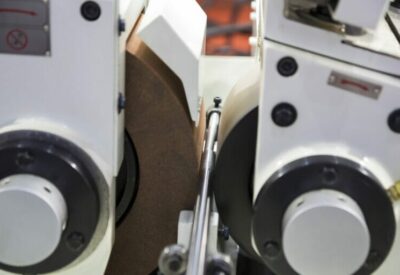

Our bar stock metals are available in various stainless steel and nickel alloys, depending on the application required. They can be manufactured up to 0.750” to customer specifications.

Our centerless grinding capabilities allow for additional customization. The workpiece is constantly fed through the machine, between the grinding wheel and regulating wheel. The precision allows for exact customer dimensions and tight tolerances to be met, alongside improved surface finish.

Precision Cutting

Our most customizable and precise product line is our CNC machining. This process is considered subtractive manufacturing, as precise cuts are made to create a product from a piece of metal.

We use CAD (computer aided design) and CAM (computer aided manufacturing) files to give the machine exact cutting commands, resulting in the right product every time.

Cold Heading

Our cold heading wire is available in multiple alloys, including stainless steel, nickel and copper. The copper-moly coating on our wire securely bonds to the wire surface, formulating specifically for the most difficult cold and warm-formed parts.

This coating, and our metal alloys allow for cold or hot heading use, to manufacture precise products like bolts, blind rivets, fasteners and more.

Custom Profiles

Our shaped wire has many standard profiles, from round to rectangle to natural rolled. However, we also can customize to exact profiles that you need outside of our standard options.

Our profiles are manufactured on specialist equipment designed and built in-house with each line having in-line laser measuring – guaranteeing dimensional accuracy. Our capabilities ensure consistency and offer our customers the opportunity to develop complex or demanding requirements.