Almost every company across every industry is constantly searching for ways to maximize efficiency, reduce waste, and increase profits. With ambitions of reaching net-zero carbon emissions by 2050, and stringent standards for manufacturing quality, the Aerospace industry is seeing a growing movement towards a circular economy.

A circular economy prioritizes making the most out of existing resources and materials, keeping products in use for as long as possible, while minimizing the environmental impact. Not only does a circular economy promote environmental sustainability, but it can put economic growth on a sustainable pathway.

In this blog, we will analyze a few of the trends shifting the Aerospace industry towards a circular economy, and how our precise product lines support efficient, sustainable, and high-quality Aerospace manufacturing.

Alternate Energy Sources

To minimize the overall climate impact of the Aerospace industry, and move towards net-zero carbon emissions, aviation manufacturing faces two main challenges; improving sustainability in the manufacturing process and decreasing emissions during flight. Due to the importance of high-strength, custom materials for critical Aerospace components, and the need for efficiency, improving manufacturing sustainability has become a complex endeavor.

Alternative fuel and energy sources for flight and manufacturing plants is one way to limit the overall emissions from this industry. Some of the innovations slowly making their way into this industry include sustainable aviation fuels such as biofuels, and alternative renewable energy sources powering manufacturing plants, as well as aircraft propulsion. Limiting the globally large energy consumption in aviation manufacturing plants and during flight will make a considerable difference in the overall carbon emissions of the industry.

Along with the sustainability benefits of alternative energy sources, energy recovery systems are initiating the start of a truly circular economy in Aerospace. These systems can capture, and reuse heat and energy generated during various manufacturing processes, limiting emissions and conserving valuable resources. Examples of these valuable sustainability systems include:

- Air-to-Air Recovery Systems which collect heat from exhaust systems and can be used to control the temperature of a facility.

- Air-to-Liquid Recovery Systems also collect heat from an exhaust stack, but use the energy to provide glycol, thermal oil or heat up water in a production plant.

- Regenerative Braking Systems which recover energy during deceleration and can be implemented back into power auxiliary systems.

Material Reuse and Extended Lifespan

Due to the stringent standards for product specifications in Aerospace, and the intense material conditions of heat and pressure, the reuse of materials requires excellent durability. As a globally trusted, multi-faceted manufacturer, we understand the requirements of quality and long-lasting performance in demanding Aerospace applications.

To avoid unnecessary waste, manufacturing downtime, and unreliable performance, trust the unique qualities of our military-grade product offerings, such as:

- High-Strength and Heat Resistance from our Bar Stock and Cold Heading alloys.

- Reduced Friction in High-Stress Areas with our Aerospace Bushings.

- Corrosion Resistance and Strength with our Wire Rope products.

- Flexibility and High Breaking Strength from specialized Aircraft Control Cable Assemblies.

Additional Innovations

Despite a circular economy being an emerging concept in this industry, which is yet to see widespread use, there are various innovations being researched and developed to achieve it in the future. Some prime examples of ways material reuse, limited energy and waste consumption, and more are being trialed include:

- Aircraft Deconstruction and Material Recovery with planes no longer in use.

- Recycled Materials being used in aircraft interior spaces such as the cabin and cockpit.

- Predictive Maintenance to limit unnecessary repairs and waste in advance.

- Life Cycle Assessments that prioritize product design and material selection for longer lasting performance, enhancing durability and material lifespan.

Our Mission Critical Product Offerings

Maximizing your efficiency and creating a sustainable and financially savvy manufacturing process is made easy with our quality mission critical products. Explore a few of our trusted mil-spec offerings below.

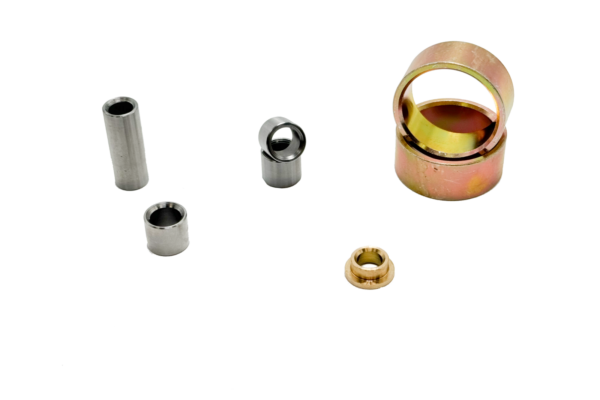

Premium Aerospace Bushings

For quality products that deliver consistent, durable Aerospace performance, look no further than our premium line of Aerospace Bushings. Our vast selection of available grades and unprecedented access to raw materials allow us to produce both standard and build-to-print Bushings in a timely manner.

These small aircraft parts are used in both Aerospace and Military applications. They are crucial for reducing friction in key parts of an aircraft and act as a barrier between moving parts, ensuring that they glide smoothly against each other, with minimal resistance. Reducing friction without oil or grease is especially important in high-stress areas where metal-on-metal contact could lead to wear and potential failure.

Custom Aircraft Cable

Our durable, high strength Aircraft Cable offers a globally trusted solution for flight control, landing gear, emergency systems and other mission critical Aerospace applications. Our material options and varying cable constructions ensure the versatility to meet all of your requirements.

We manufacture high-quality Aircraft Cable at our AS9100 certified Pomfret, Connecticut Loos and Company and Milton, Florida Strand Core locations. We maintain QPL (Quality Products List) for many military applications and specific customer approvals for manufacturing Wire Rope, Cable and Strand for OEM and international specifications.

Investing in our Mission Critical Quality

Unmatched quality, precision and industry knowledge make Central Wire Group of Companies a globally trusted supplier to the Aerospace industry. Our expertise and various engineering capabilities create solutions that meet exact product requirements and offer long-lasting performance in demanding Aerospace applications.

For more information on our custom Aerospace products and their most common uses, visit our industry webpage today!