In industries where every connection, every lift, and every structural element matters, knowing how a product was made is just as important as the product itself. That is why traceability has become a defining expectation across Aerospace, Defense, Marine, Construction, and Industrial sectors.

For Cable Assemblies and Wire Rope, traceability is more than documentation. It is a complete record of origin, manufacturing, testing, inspection, and certification—a full narrative that gives customers confidence before installation ever begins. At Loos & Company, this level of transparency is standard practice for every assembly, every cable, and every production lot.

Cable Assemblies: Traceability From Start to Finish

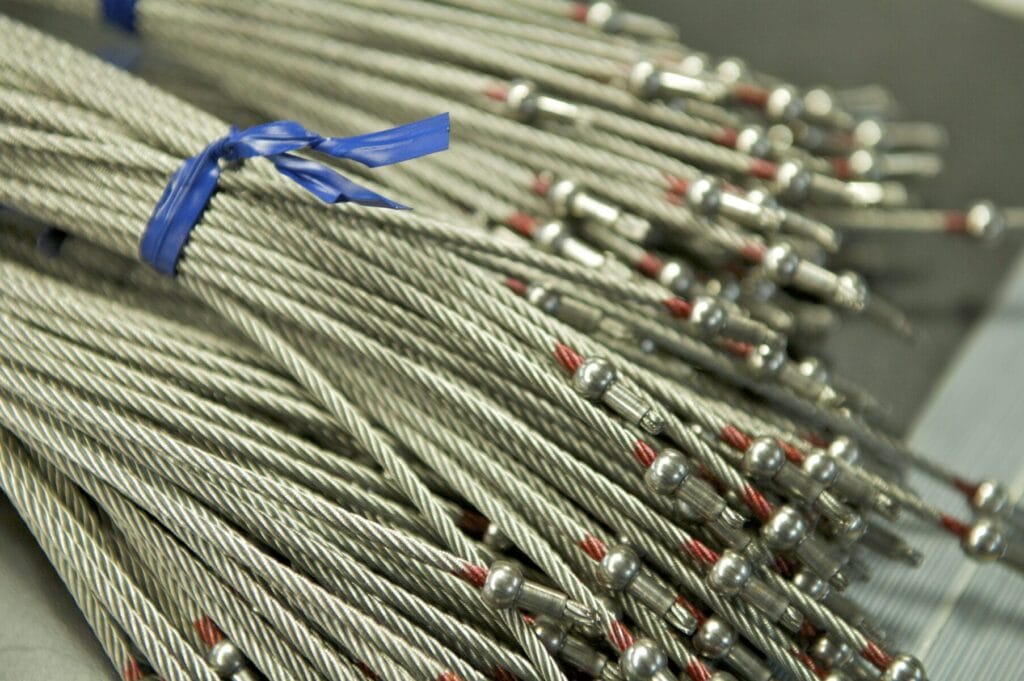

A Cable Assembly is a system of multiple components—wire, fittings, hardware, coatings, proof-loading, and inspection. True traceability means documenting each stage so customers can confirm quality at every point in the process.

At Loos & Company, each Assembly carries its own identity. The wire used in construction is traceable back to its melt source and chemical composition. The fittings, sleeves, and hardware used in termination are recorded by lot and specification. The swaging process is documented with inspection results that validate compression integrity. Proof-load testing and final visual examinations are logged and tied directly to that Assembly’s record.

This creates a closed-loop traceability chain:

Raw material → manufacturing → assembly → proof-testing → certification → shipment.

When an Assembly arrives at a customer’s facility, it brings evidence—not assumptions. Certificates of Conformance, inspection reports, and production documentation confirm exactly how it was built, what it was made from, and that it meets the intended standard.

In sectors like Aerospace, Architecture, and Industrial lifting, that level of transparency directly supports safety and compliance.

Wire Rope and Strand: Quality You Can Follow

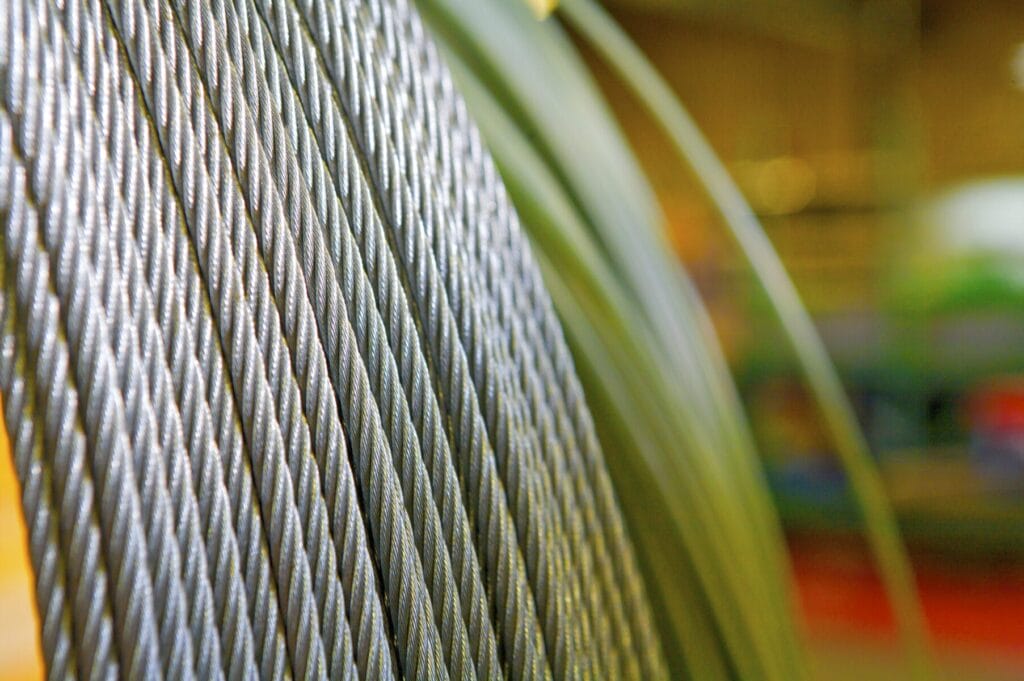

Traceability is equally essential for Cable, Strand, and Wire Rope—materials that often serve as critical load-bearing components in Marine, Defense, and Industrial systems.

Every reel begins with melt data that identifies the alloy source and chemistry. As wire is drawn, stranded, and laid into its final construction, mechanical test results, tensile values, and dimensional checks are recorded and attached to the production lot. Coatings, lubricants, and surface finishes are verified and logged.

The final product is more than a coil of Cable—it is a documented sequence of events, materials, and validations. Customers receive a cable whose history can be followed from start to finish with complete clarity.

Inspection results—from tensile strength to coating adhesion—are tied directly to lot numbers. If a customer wants to review mechanical properties for an order produced years ago, the traceability system ensures the records can be retrieved.

This is what separates documented quality from generic supply.

Transparency Reinforces Compliance

Across industries, compliance frameworks require verifiable manufacturing records:

- Aerospace approvals rely on material certifications and inspection data.

- Marine installations require documentation for corrosion resistance and mechanical properties.

- Industrial systems need proof of load capacity and construction accuracy.

Traceability makes that possible. Instead of trusting a label, operators and engineers can reference the documented history of the Cable or Assembly they’re installing. Traceability becomes not only a quality tool—but a compliance tool.

This is especially vital in applications where Cable Assemblies or Wire Rope serve as primary structural or load-bearing components. The ability to demonstrate that materials match specification, that tests were performed, and that records are complete is essential for audits and safety reviews.

A System Designed Around Accountability

Loos & Company’s traceability framework is built intentionally to go beyond the basics. Each step in the production cycle includes checkpoints that feed into the product’s final documentation.

We track:

- Melt source and alloy chemistry

- Dimensional and mechanical test results

- Stranding and lay operations

- Coating or finishing steps

- Swaging pressure and termination inspection

- Proof-load testing

- Final quality reviews

Every piece of information is tied to the lot or Assembly number that follows the product from production to shipment. It ensures there are no unknowns in the process—only verifiable data.

This level of documentation reflects a simple truth: Traceability exists because quality must be proven, not implied.

Traceability Strengthens Customer Confidence

When customers receive traceable Cable Assemblies and Wire Rope, they gain visibility into how every component was produced. That transparency eliminates uncertainty. It reassures engineers that material chemistry matches requirements. It confirms the Assembly was proof-tested. It verifies that the Wire Rope they’re installing meets the exact mechanical properties specified.

Traceability turns quality into something that can be checked, not assumed. It transforms a shipment into a fully documented system.

For mission-critical industries, that assurance carries real weight.

Global Traceability, Unified Standards

With Loos & Company operating inside the larger Central Wire network, traceability is reinforced across facilities in the United States, Canada, and the United Kingdom. Each location follows the same documentation and inspection requirements, ensuring customers receive identical quality and identical traceability—regardless of where their order was produced.

When a customer audits one facility, they understand all of them. When they receive a shipment from one region, its documentation mirrors that of the others.

This unified system supports global supply chain confidence.

The Value of Traceability in Every Application

Whether used in Aircraft control systems, Marine rigging, Architectural tension structures, or Industrial lifting and motion systems, Cable Assemblies and Wire Rope must perform without compromise.

Traceability protects that expectation. It provides the transparency customers need to verify quality, confirm compliance, and align with safety requirements long before field installation.

And because every record is maintained, traceability continues long after the product is delivered—supporting audits, inspections, and long-term maintenance programs.

Next Steps

Explore our Cable Assemblies and Cable to see how Central Wire delivers accountability through testing, certifications, and products built to last.

For project guidance or to request a quote, contact our team today at sales@loosco.com