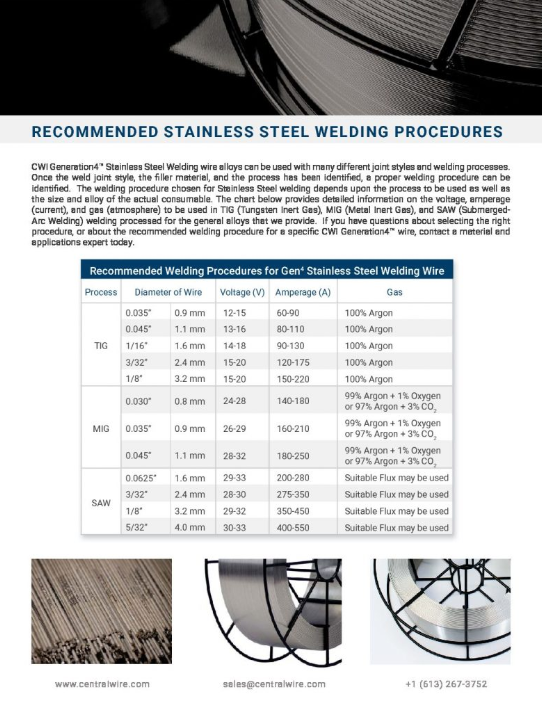

CWI Generation4™ Stainless Steel and Nickel Welding wire alloys can be used with many different joint styles and welding processes. Once the weld joint style, the filler material, and the process has been identified, a proper welding procedure can be identified. The welding procedure chosen for Stainless Steel and Nickel welding depends upon the process to be used as well as the size and alloy of the actual consumable. The charts below provide detailed information on the voltage, amperage (current), and gas (atmosphere) to be used in TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), and SAW (Submerged-Arc Welding) welding processed for the general alloys that we provide. If you have questions about selecting the right procedure, or about the recommended welding procedure for a specific CWI Generation4 ™ wire, contact a CWI material and applications expert today.

第 4 代不锈钢焊丝的推荐焊接程序

| 过程 | 线径 | 电压 (V) | 安培数 (A) | 气体 | |

|---|---|---|---|---|---|

| 氩弧焊 | 0.035" | 0.9 毫米 | 12-15 | 60-90 | 100% 氩气 |

| 0.045" | 1.1 毫米 | 13-16 | 80-110 | 100% 氩气 | |

| 1/16" | 1.6 毫米 | 14-18 | 90-130 | 100% 氩气 | |

| 3/32" | 2.4 毫米 | 15-20 | 120-175 | 100% 氩气 | |

| 1/8" | 3.2 毫米 | 15-20 | 150-220 | 100% 氩气 | |

| 米格 | 0.030" | 0.8mm | 24-28 | 140-180 | 99% 氩气 + 1% 氧气 - 或 - 97% 氩气 + 3% CO2 |

| 0.035" | 0.9mm | 26-29 | 160-210 | 99% 氩气 + 1% 氧气 - 或 - 97% 氩气 + 3% CO2 | |

| 0.045" | 1.1mm | 28-32 | 180-250 | 99% 氩气 + 1% 氧气 - 或 - 97% 氩气 + 3% CO2 | |

| 锯 | 0.0625" | 1.6mm | 29-33 | 200-280 | 可以使用合适的助焊剂 |

| 3/32" | 2.4毫米 | 28-30 | 275-350 | 可以使用合适的助焊剂 | |

| 1/8" | 3.2毫米 | 29-32 | 350-450 | 可以使用合适的助焊剂 | |

| 5/32" | 4.0mm | 30-33 | 450-550 | 可以使用合适的助焊剂 | |

第 4 代不锈钢镍焊丝的推荐焊接程序

| 过程 | 线径 | 电压 (V) | 安培数 (A) | 气体 | |

|---|---|---|---|---|---|

| 氩弧焊 | 0.035" | 0.9 毫米 | 12-15 | 60-90 | 100% 氩气 |

| 0.045" | 1.1 毫米 | 13-16 | 80-110 | 100% 氩气 | |

| 1/16" | 1.6 毫米 | 14-18 | 90-130 | 100% 氩气 | |

| 3/32" | 2.4 毫米 | 15-20 | 120-175 | 100% 氩气 | |

| 1/8" | 3.2 毫米 | 15-20 | 150-220 | 100% 氩气 | |

| 米格 | 0.035" | 0.9mm | 26-29 | 150-190 | 75% 氩气 + 25% 氦气 |

| 0.045" | 1.2mm | 28-32 | 180-220 | 75% 氩气 + 25% 氦气 | |

| 1/16" | 1.6mm | 29-33 | 200-250 | 75% 氩气 + 25% 氦气 | |

| 锯 | 3/32" | 2.4毫米 | 28-30 | 375-350 | 可以使用合适的助焊剂 |

| 1/8" | 3.2毫米 | 29-32 | 350-450 | 可以使用合适的助焊剂 | |

| 5/32" | 4.0mm | 30-33 | 400-550 | 可以使用合适的助焊剂 | |