Automotive Innovation & Reliability

In the automotive industry, there are many small parts working together. Our metals, wires and cables help keep cars, trucks and RVs safe, structurally sound and performing.

Below you can see our product lines catering to the industry and the applications of our products in the automotive industry.

Product Lines

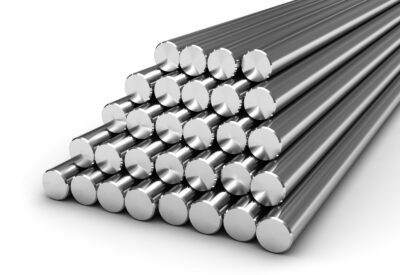

Premium stainless steel and nickel bar stock manufactured up to 0.750” to customer specifications. Highly customizable for many end-use applications and mission critical industries.

Custom cable assemblies crafted with precision and expertise. Our aircraft, military, and commercial cable assemblies are all highly customizable, and are durable enough to withstand demanding applications.

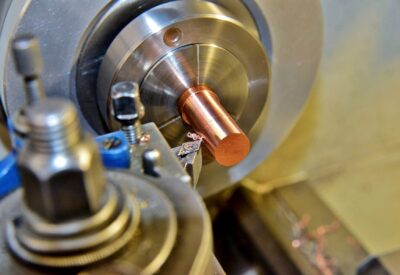

Custom CNC manufacturing can use many different alloys including stainless steel, aluminum, brass, bronze, copper and nickel. Custom parts are tested in-house to ensure quality, and precise machining produces the perfect product every time.

Cold heading wire is available in stainless, nickel, and copper base alloys. Quality raw material for use as fasteners, blind rivets, screws and bolts

High quality fine wire produced in sizes from 0.001” up to 0.032” with custom sizes available by request. Tempers range from soft annealed to spring temper

Corrosion resistant spring wire comes in stainless steel and nickel alloys, boasting excellent coiling ability at high speeds needed no additional lubricant. Manufactured in sizes from 0.022” to 0.625”.

Welding wire produced for various techniques including MIG, TIG and SAW welding. Available in stainless and nickel-based alloys.

Our products are trusted for reliable and durable use in the automotive industry.

As we continue to drive our quality manufacturing forward, we find new ways to supply motor vehicles, including:

Product Applications

Welding

Consistent welds to ensure safety and performance in the production of cars and trucks. The automotive industry leaves no margin for error when it comes to welding. With the safety of drivers in mind, our welding wire is manufactured to keep vehicles safe and reliable.

Current automotive production would not be possible without the ability to weld many metals in various shapes and sizes quickly and precisely, and we take pride in offering unparalleled support to these customers.

Engine Components

Highly customizable bar stock options can create reliable engine components built to last and perform, such as crankshafts and connecting rods. Precision machining allows bar stock metals to be customized to the exact requirements of an engine.

Processes like CNC milling, turning and grinding create valve stems, connecting rods, crankshafts, camshafts, and other components that keep a vehicle running smoothly.

Mechanical Linkages

Functions like throttle control, clutch control, and initiating a parking brake require durable cables to put the command into action and remain safe while driving. Our cable assemblies are perfect for all commercial applications, including ones that are important for safety.

The cable assemblies used for linkages like throttle controls and clutch controls ensure responsive and smooth acceleration and transmission engagement, while having the durability to last.

Suspensions

Durable and strong spring wire in nickel and stainless-steel alloys make for suspension systems that can handle the harsh demands of this industry.

Corrosion resistance, excellent coiling ability at high speeds, and no need for lubricant make our spring wire a great choice for suspension. Not only will our spring wire last, but it will also perform well without wearing down or rusting.

Ignition Systems

Ignition system components such as spark plugs, and ignition coils use fine wire for its flexibility and miniscule diameter. Quality fine wire is necessary to ensure ignition components perform when they are needed most, especially in vehicles being driven in less than ideal weather conditions.

Shafts, Axles

Strong bar stock metals can make up much of the structural components of a vehicle, with corrosion resistance and strength keeping the vehicle structurally sound. Avoiding rust is a key for any car owner, to maintain the visual integrity and performance of a vehicle, while even rougher driving conditions are not enough to damage strong bar stock metals in their shaft and axle applications.

Bolts, Screws, Etc.

Custom manufacturing can create the exact bolts, screws, rivets or fasteners needed to bring everything together in the automotive industry. Our custom machining features in the smallest automobile parts as well. Creating custom CNC machine parts means you have the right part every time.