In applications where heat, vibration, and mechanical stress converge, longevity becomes the ultimate measure of material value. Wire products that operate under continuous electrical load, or that must create welds capable of lasting decades, cannot simply meet spec at installation. They must continue to perform under conditions that test their structure every day.

Central Wire’s Welding Wire and Resistance Wire illustrate two distinct but equally demanding paths to longevity—one through structural strength, the other through thermal and electrical endurance. Both rely on metallurgy, precision manufacturing, and consistent testing to ensure they deliver long-term performance across industries worldwide.

Welding Wire: Longevity Through Structural Integrity

A weld is not just a connection—it is a critical structural point where longevity is put to the test. A welded joint must outlast both the surrounding metal and the conditions it will face over its lifetime: heat, vibration, moisture, corrosive environments, and repeated strain.

The longevity of a weld starts with the wire. Central Wire produces MIG, TIG, and SAW Wire using controlled chemistry and surface preparation to ensure smooth arc stability, strong fusion, and consistent deposition. Uniform wire diameter prevents feeding fluctuations, reducing the risk of porosity or weak points that could shorten weld life.

But longevity is ultimately proven in service. In Automotive manufacturing, welds must endure years of vibration and temperature cycling. In Aerospace, weight-to-strength ratios are critical, and long-term fatigue resistance determines the lifespan of welded structures. In Oil & Gas, corrosion-resistant alloys are the difference between predictable performance and premature failure.

A weld built to last begins with a wire built to last. That’s why we test every batch for mechanical strength, chemical consistency, and cleanliness—because longevity depends on what happens before the spark ever strikes.

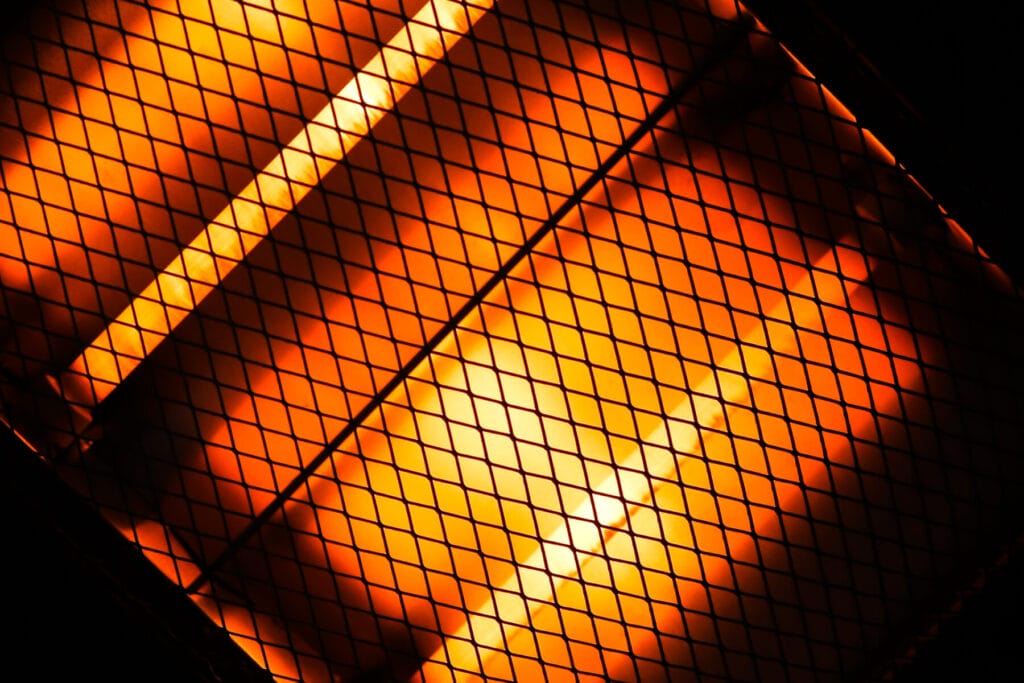

Resistance Wire: Longevity Under Heat and Load

Resistance Wire lives in an entirely different world, where longevity is measured by the wire’s ability to maintain stable performance under extreme temperatures and electrical load. Unlike structural wire, Resistance Wire must deliver predictable heating behavior hour after hour, sometimes in continuous service environments.

At Central Wire, longevity in Resistance Wire starts with alloy selection. Nickel, chromium, and iron-based alloys are engineered to resist oxidation, maintain electrical consistency, and withstand temperatures that would degrade ordinary materials. The wire must hold its resistance value over time, resisting drift that could compromise performance or safety.

Applications reveal just how essential longevity is. In Industrial heating elements, the wire is exposed to repeated thermal expansion and contraction. In Consumer appliances, it must deliver years of dependable service without burnout. In Aerospace and high-temperature equipment, it must operate within tight tolerance windows at elevated temperatures.

The ability of Resistance Wire to continue performing after thousands of heat cycles is the definition of engineered longevity.

Metallurgical Control

Whether designing for weld integrity or high-temperature resistance, longevity begins with metallurgy. The internal grain structure, alloy composition, and surface condition determine how long the wire can tolerate stress before failure.

For Welding Wire, this means controlled deoxidizers, stable alloy chemistry, and surface cleanliness that supports strong fusion. For Resistance Wire, it means oxidation resistance, thermal stability, and metallurgical consistency that prevent drift or degradation.

In both cases, longevity is an outcome of careful control—not a trait added after the fact.

Predictive Testing

Long-term performance is validated through testing designed to simulate years of use. Central Wire applies destructive and non-destructive evaluations to confirm wire behavior under conditions that mirror real applications.

For Welding Wire, this includes mechanical tensile tests, bend tests, macroetch analysis, and arc stability assessments. For Resistance Wire, testing verifies resistance values, temperature stability, oxidation behavior, and long-cycle thermal endurance.

These processes predict how wire will behave years into service—not just the day it ships. Longevity must be demonstrated early, and we validate it with every batch.

Longevity Across Industries

The industries that rely on Welding Wire and Resistance Wire are industries where failure carries consequences:

- Aerospace: fatigue-resistant welds and stable high-temperature wire.

- Automotive: long-life welds in chassis, exhaust, and structural systems.

- Industrial Manufacturing: heating wire and welded joints that withstand continuous duty cycles.

- Oil & Gas: corrosion-resistant welds and high-temperature wire for processing environments.

- Consumer Goods: appliances and equipment that must function reliably for years.

In each case, the long-term performance of the wire contributes directly to the lifespan of the end product.

Longevity Through Consistency

Longevity depends on repeatability—wire made today must behave the same as wire made next year or five years from now. With facilities in the United States, Canada, and the United Kingdom, Central Wire maintains harmonized manufacturing standards to ensure consistent alloy chemistry, surface condition, tensile properties, and resistance values across every production location.

The Central Wire Advantage

Longevity is the result of controlled metallurgy, precise manufacturing, rigorous testing, and decades of engineering insight. Central Wire’s Welding Wire and Resistance Wire are designed to meet the long-term expectations of the industries that rely on them.

Whether delivering structural longevity through weld integrity or thermal longevity through stable resistance performance, our wire products are engineered to endure.

Next Steps

Explore our Welding Wire and Resistance Wire to see how Central Wire delivers accountability through testing, certifications, and products built to last.

For project guidance or to request a quote, contact our team today at sales@centralwire.com