The Different Types of Arc Welding and Their Benefits

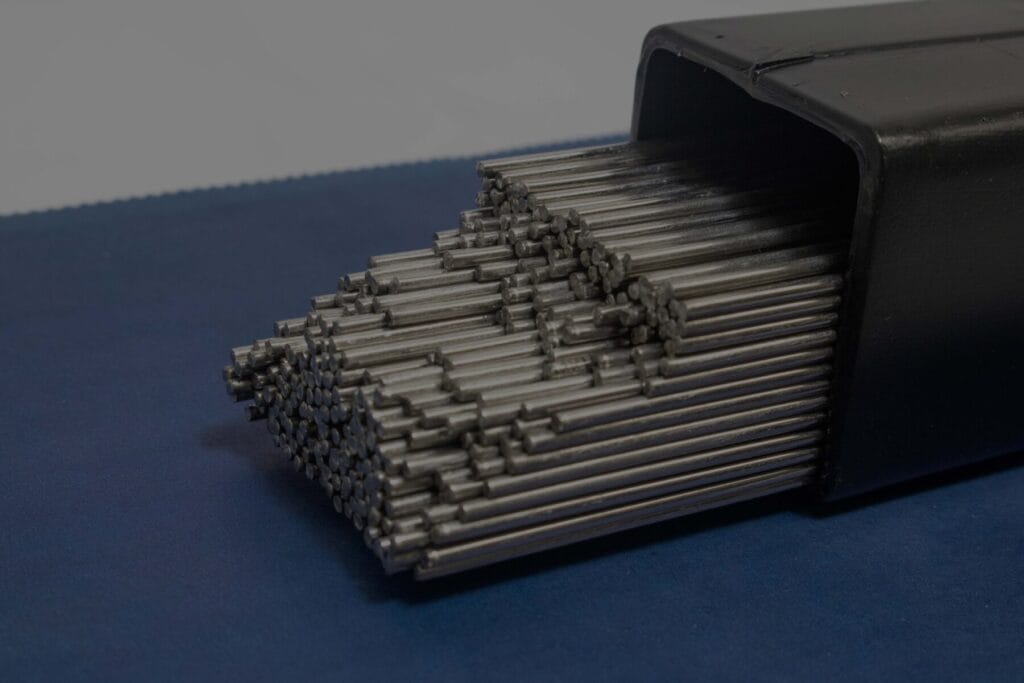

At Central Wire, our specialized Generation4™ Welding Wire is designed for superior strength and adaptability.

A Sustainable Future: The Renewable Sectors We Serve

Our continued innovation in manufacturing for this industry reflects our dedication to creating a greener, more resilient world for generations to come.

The Importance of Full Lot Traceability in Welding Wire

In manufacturing, full lot traceability creates accountability along every step of the process from raw material distributor to a products end-use application.

How CWI Products Support the Construction Industry

In a labor-heavy industry like Construction, it is essential to use materials that work just as hard as you do.

How Does Your Beer Make it to the Table?

In a world where home brewing equipment and other machinery have seemingly simplified the beer making process, there are still challenges and demands that must be met to ensure the process works out.

Car Restoration and Welding Techniques

Beyond sourcing parts and deciding on paint, interior design and other aesthetic features, one of the main tasks is welding repairs. There are plenty of body shops capable of doing this, but many car restoration jobs are preferably done by the individual.

Overcoming the Challenges of Stainless Steel Welding

Welding presents very unique challenges, many of which revolve around using the right material so that your weld lasts and maintains over a long period of time. One material that can present some challenges is welding using stainless steel.

CWI: Serving the Entire Oil and Gas Industry

The oil and gas industry can be taxing, on not just workers but on products as well. Any materials being used need the appropriate qualities to withstand the harsh conditions of this industry.

What’s the Difference Between MIG and TIG Welding?

Chances are, you’ve crossed paths with MIG and TIG welding in conversations about metalwork. But what are the core differences between these two types of welding?

3 consejos para obtener soldaduras TIG perfectas en acero inoxidable

Para conseguir soldaduras TIG de acero inoxidable impecables, es necesario practicar. Sin embargo, utilizar las herramientas correctas y tener los conocimientos esenciales pueden ayudarle a tener éxito.