The Different Types of Arc Welding and Their Benefits

At Central Wire, our specialized Generation4™ Welding Wire is designed for superior strength and adaptability.

A Guide for Wire Rope Materials

Whether your project is focused on aesthetics, flexibility, strength or durability, we are able to provide the right solution.

Using Alloy 17-7PH® in Spring Wire

One of the strongest and most versatile alloys we provide, 17-7PH® is a standout in this product line and beyond.

The Differences Between INCONEL® and MONEL®

Two of our most versatile alloy series are Inconel® and Monel®, both falling under our Nickel Specialty Alloy category.

The Innovation of Solar Tracking Systems

Amid concerns about the amount of energy being created in the solar sector, this innovative solution helps maximize the production of energy while the sun is visible.

4 Ways We Ensure Cold Heading Material Consistency

Designed to withstand mission critical environments and harsh conditions, material consistency and strength is crucial to the performance of all Cold Heading products.

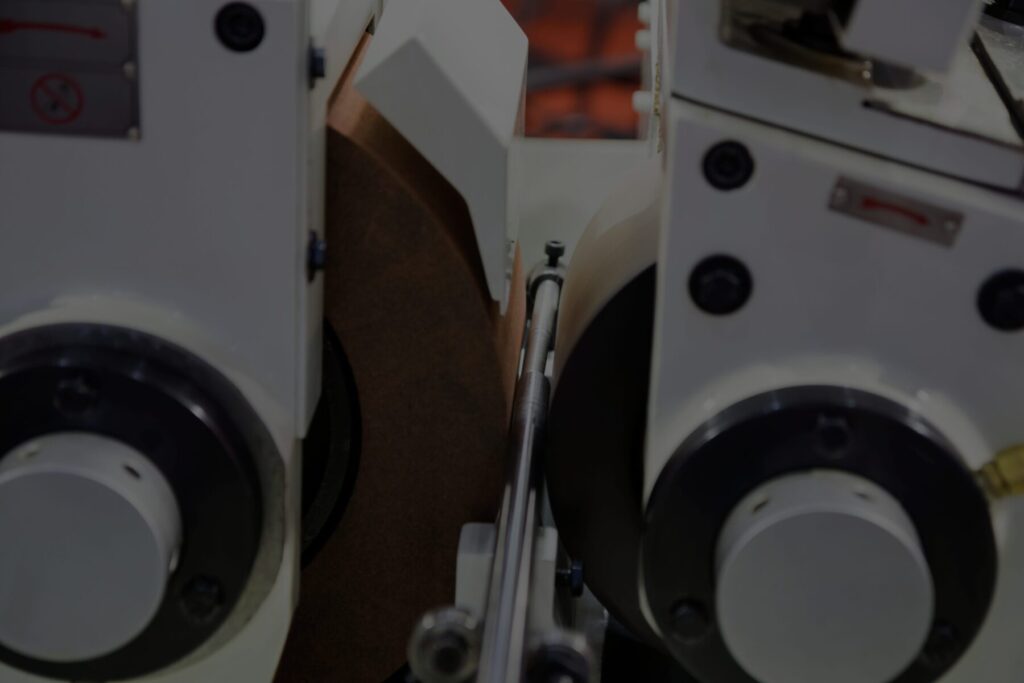

CWI’s Precision Machining Capabilities Serving Markets with the Highest Quality Requirements

Our CNC Machining tools include milling machines, turning machines and more, which help us meet your exact specifications!

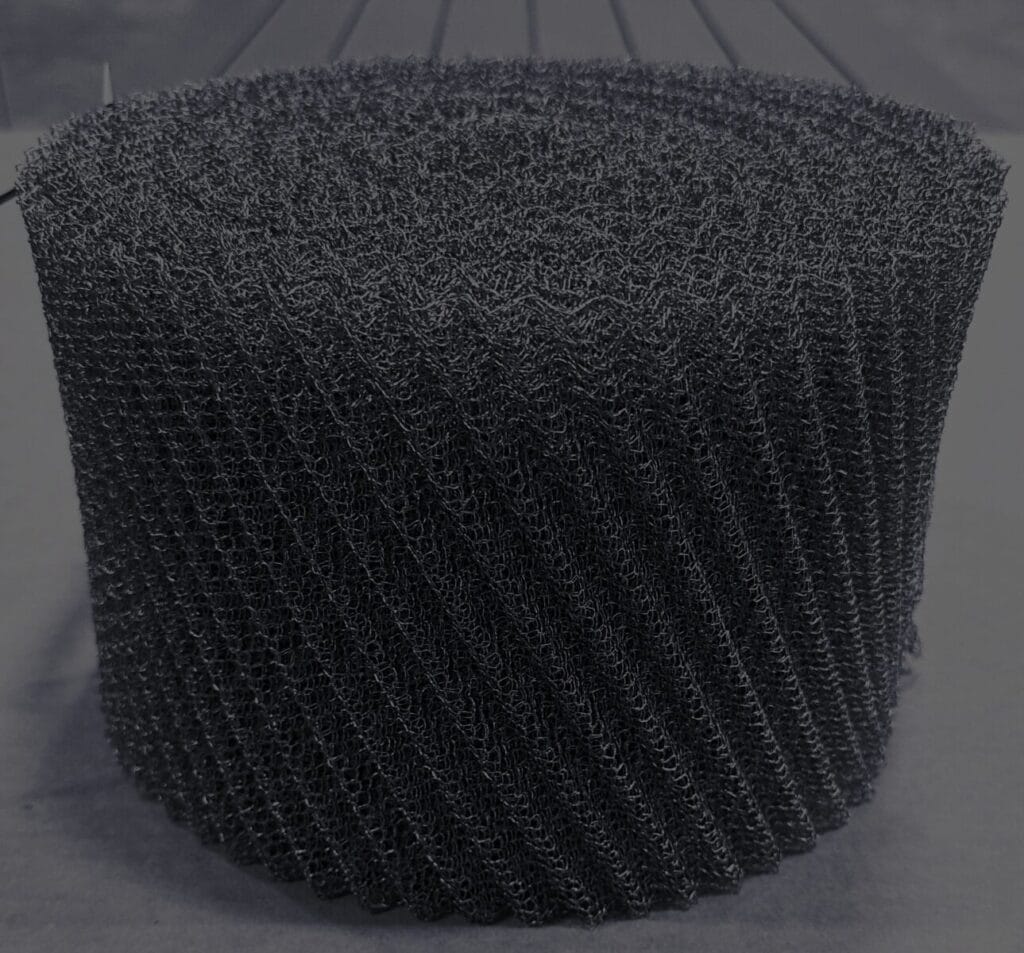

Manufacturing Tech-Mesh™: From Raw Materials to Customization

The precision engineering behind our Tech-Mesh™ line redefines industry standards and sets us apart from the competition.

The Importance of Precipitation Hardening

Precipitation hardening is a heat treatment process which increases the tensile strength and hardness of various alloy families. In some cases, this process can increase the yield strength of an alloy fivefold.

Subsea Marine Research and CWI Products

When conducting Marine research, precision and material durability are required to produce accurate results.

The Challenges for Aerospace Cable Assemblies

When it comes to the intricate world of Aircraft Cable Assemblies, the challenges faced are both diverse and demanding.

Coated Cable for Harsh Industry Conditions

Our Coated Cable product line is built to help protect cables in harsh industries and ensure performance doesn’t waver.

How to Choose Between Galvanized & Stainless Steel

Choosing between Galvanized and Stainless Steel for Wire Rope, Cable and Strand products often comes down to one critical issue: long-term performance and reliability.

Mastering Materials: A Deep Dive into Bar Stock Alloys

In the world of manufacturing, the choice of materials can significantly impact the quality and performance of the end-use product.

Safety and Strength Cables in the Mining Industry

Limiting downtime and maximizing efficiency is key to keeping business on track while keeping workers protected from any of the dangers in Mining applications.

A Sustainable Future: The Renewable Sectors We Serve

Our continued innovation in manufacturing for this industry reflects our dedication to creating a greener, more resilient world for generations to come.

The Critical Wire, Cable & Assembly Products that Serve the Medical Industry

The Medical Industry leaves no room for error, requiring precise materials that offer reliable performance.

The 7 Differentiators of CWI Tech-Mesh™

The 7 differentiators that set us apart in the industry and make CWI the right choice for your next Knitted Mesh project

A Look into Aircraft, Military, & Lock-Clad Assemblies

At Loos & Company, we are proud to serve mission critical industries such as Aerospace and Military and Defense with quality and excellence.

High-quality Slicklines Protect Against Costly Downtime

Choosing CWI helps protect you from slickline failure, saves valuable downtime, and keep projects and jobsites safe and efficient.

CWI Alloys for Corrosion Resistance

Metals can corrode for many reasons, including metal reacting with a substance like oxygen or hydrogen, or a metal being placed under too much stress causing the material to crack.

L'importance de la traçabilité intégrale des lots pour les fils de soudure

Dans le domaine de la fabrication, la traçabilité intégrale des lots permet de rendre des comptes à chaque étape du processus, depuis le distributeur de matières premières jusqu'à l'utilisation finale du produit.

4 Avantages du remplacement des poulies en acier et en aluminium par des poulies en nylon moulé

En tant que choix de l'industrie des câbles métalliques pour tous vos besoins en matière de réas, nous connaissons les défis que vos applications de réas peuvent poser au produit.

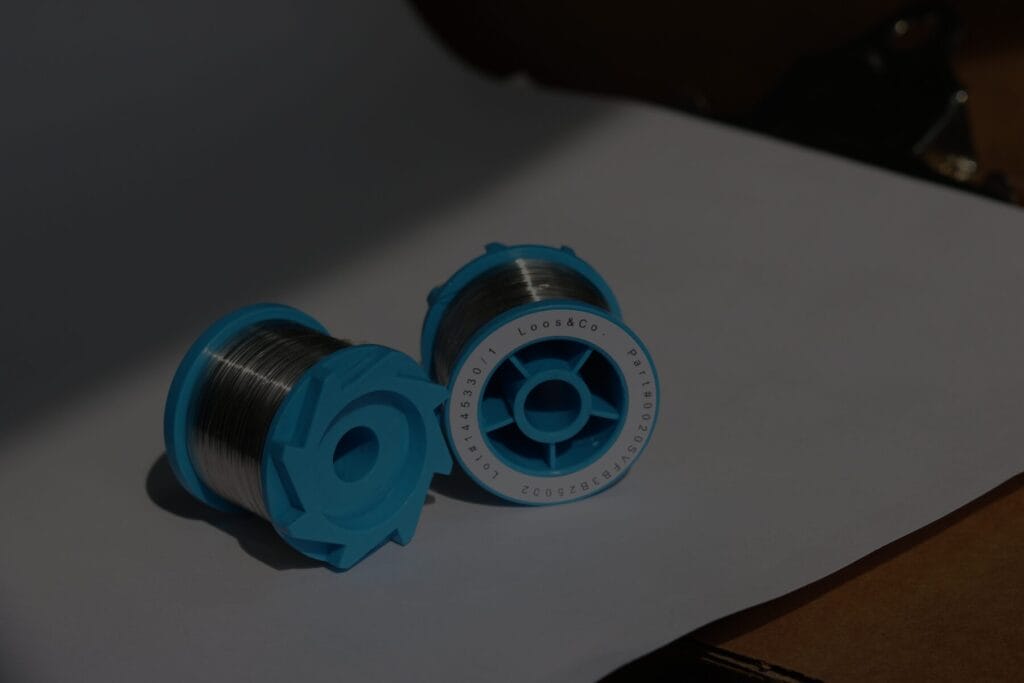

Pourquoi choisir CWI Fine Wire

Notre fil peut être utilisé seul, en tant que brin unique, ou être transformé en câble métallique, en enroulant un nombre spécifique de fils simples autour d'un fil central.