Military and Defense, Mission Critical Success

We pride ourselves on being industry leaders in MIL-Spec products and manufacturing. Our products can withstand demanding industries in mission critical industries.

We manufacture our military and defense products to the highest standards, as there is no room for error. We proudly domestically manufacture mission critical components that the US Government can rely on.

Below are our product lines catering to the industry and the applications of our products in the military and defense industries.

Lignes de produits

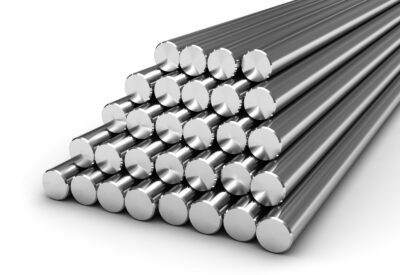

Premium stainless steel and nickel bar stock manufactured up to 0.750” to customer specifications. Highly customizable for many end-use applications and mission critical industries.

Assemblages de câbles sur mesure réalisés avec précision et expertise. Notre avionLes assemblages de câbles pour les applications militaires et commerciales sont tous hautement personnalisables et suffisamment durables pour résister à des applications exigeantes..

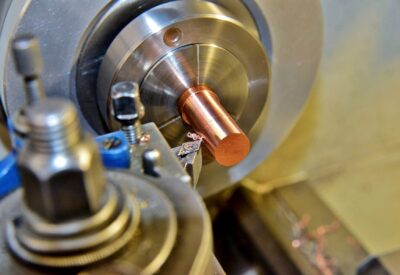

Custom CNC manufacturing can use many different alloys including stainless steel, aluminum, brass, bronze, copper and nickel. Custom parts are tested in-house to ensure quality, and precise machining produces the perfect product every time.

Cold heading wire is available in stainless, nickel, and copper base alloys. Quality raw material for use as fasteners, blind rivets, screws and bolts.

Involves a meticulous process of extruding a plastic jacket onto avion cable or wire rope, to enhance durability, functionality, and improve aesthetics. More resistant to abrasion than ordinary cables and adds resilience for harsh conditions.

Welding wire produced for various techniques including MIG, TIG and SAW welding. Available in stainless and nickel-based alloys.

Our AS9100 certified military products are manufactured with excellence, ready to take on the challenges that this mission critical industry presents. With the industry’s largest assembly inventory, we are able to produce custom assemblies for military and defense applications in a timely manner.

Here are the applications of our products in military and defense:

Applications des produits

Flight Control

Rudders, ailerons, elevators and more components that dictate a plane’s direction are controlled from the cockpit by cable assemblies. Throttle controls use cable assemblies as well, relying on quality cables for consistent and smooth acceleration. Mid-air alterations that keep flights on track, and make pilot’s jobs easier, are powered by avion cable.

Fasteners & Engine

Bar stock products are both highly customizable, and highly reliable, being manufactured from AS9100 certified metals. Whether it’s the little fasteners that keep the plane together, or the more complex engine parts that ensure take-off, descension and everything in between is done efficiently, you can trust CWI bar stock.

Emergency Systems

Our durable cable assemblies and coated cable products can be used for safety and emergency systems in aircrafts. If you’ve ever heard a pre-flight speech about emergency procedures, you’ve heard mention of a product we can provide.

Emergency exits and masks stored above seats are a few examples of safety precautions that would be opened or released by our cable products. With how critical these measures can be, having quality cables involved is crucial.

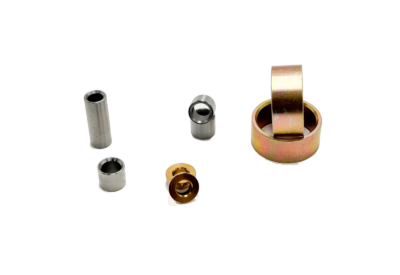

Bushings, Hardware

CWI custom manufacturing allows us to provide many smaller hardware components to the aerospace industry. From bushings to bearings to nuts and bolts, our CNC machining capabilities can be used to create the perfect product for any application.

Bushings and bearings help limit friction, and we can also manufacture the exact screw, nut or bolt needed to keep structural components together, and maximize the function of all the technology within an aircraft.

Structural Parts

Much of the structure of an aircraft can be produced from bar stock metal alloys like stainless steel and aluminum. The fuselage (main body) and wings of a plane use these metals for their lightweight structure, corrosion resistance and durability to withstand weather obstacles, long flights, heavy loads and the many other challenges of this mission critical industry.

Our AS9100 certified locations have many certifications, listed here:

Loos Naples – Naples, Florida

SPECIFICATION | DESCRIPTION |

MIL-DTL-781 | Covers wire rope terminals designed for attachment to wire rope by swaging |

MIL-DTL-8878 | Turnbuckles, Positive Safetying, General Specification intended for use in the construction of aircraft and aircraft accessories |

MS-21252C | Clip Locking, Clevis Fork |

MS-20667 | Fork End Fittings |

MS-20668 | Eye End Fittings |

MS-21254C | Turnbuckle, Eye End (For Pin) |

MS-21255C | Turnbuckle, Clip Locking, Eye End (For Wire) |

MS-21259 | Stud End Fittings |

MS-21260 | Locking Stud End Fittings |

MS-20663 | Double Shank Balls |

MS-20664 | Single Shank Balls |

MS-21251 | Turnbuckle Bodies |

MS-21256 | Locking Clips |

MS-51844 | Manches ovales |

Loos & Co. – Pomfret, Connecticut

SPECIFICATION | DESCRIPTION |

MIL-DTL-83420 QPL-83420 | Wire rope, flexible, for aircraft control (supersedes MIL-W-83420, MIL-C-5424 and MIL-W-1511) |

MIL-DTL-87161 QPL-87161 | Wire rope, non flexible, for aircraft application (supersedes MIL-W-87161, MIL-W-5693 and MIL-W-6940) |

MIL-DTL-18375 QPL-18375 | Cable, steel (corrosion-resisting, non-magnetic) flexible, preformed (for aeronautical use) (supersedes MIL-W-18375) |

MIL-DTL-87218 QPL-87218 | Cable, lockclad, for aircraft control |

MIL-DTL-6117 QPL-6117 | Wire Rope Assemblies, Aviation, Swage Type |

MIL-DTL-83140 QPL-83140 | Wire ropes, stainless steel preformed, non-rotation, for aircraft rescue hoist and cargo handling (winching) (supersedes MIL-W-83140) |

MIL-W-18242 | Wire rope and wire rope assemblies; single leg-corrosion resisting steel, minesweeping |

RR-W-410 | Federal Specification for Wire Rope and Strand |

MIL-DTL-5688 | Wire Rope Assemblies; Aircraft, Proof Testing and Prestretching |

Strand Core – Milton, Florida

SPECIFICATION | DESCRIPTION |

MIL-DTL-83420 | Wire rope, flexible, for aircraft control – supersedes MIL-W-83420, MIL-C-5424, and MIL-W-1511 |

MIL-DTL-87161 | Wire rope, non flexible, for aircraft application – supersedes MIL-W-87161, MIL-W-5693, and MIL-W-6940) |

MIL-DTL-18375 | Cable, steel (corrosion-resisting, non-magnetic) flexible, preformed (for aeronautical use) – supersedes MIL-W-18375 |

MIL-DTL-83140 | Wire ropes, stainless steel preformed, non-rotation, for aircraft rescue hoist and cargo handling (winching) – supersedes MIL-W-83140 |

MIL-DTL-18242 | Wire rope and wire rope assemblies; single leg-corrosion resisting steel, minesweeping |

RR-W-410 | Federal Specification for Wire Rope and Strand |