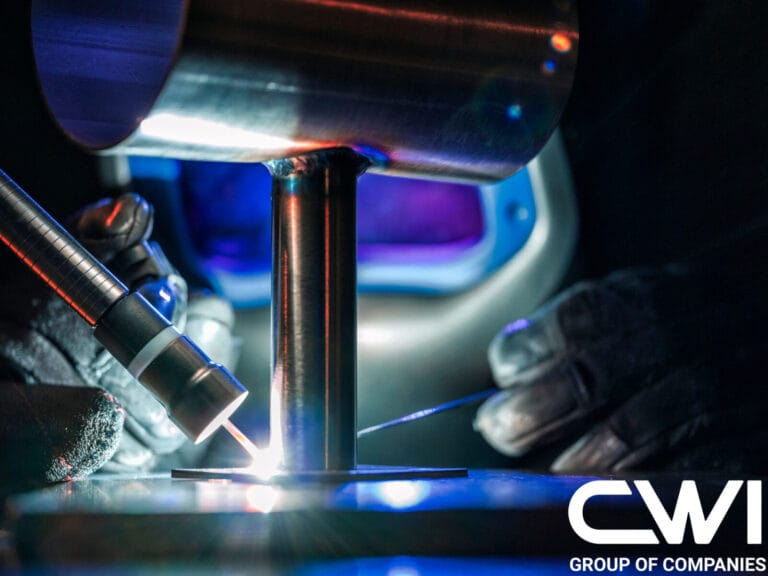

Discover our specialized Welding Wire suitable for MIG, TIG, & SAW welds. Designed for superior strength and adaptability.

Our welding wire is manufactured to your exact specifications, fulfilling a variety of filler needs for many technical processes. Whether you’re a fabricator or a wholesaler, Central Wire manufactures the MIG, TIG, and SAW welding wire you need.

Alle Schweißprodukte werden mit einem Konformitätszertifikat geliefert, in dem die physikalischen und mechanischen Eigenschaften einschließlich der Legierungschemie aufgeführt sind. Jedes Schweißprodukt wird so hergestellt, dass es seine eigene eindeutige Chargenidentifikationsnummer zur vollständigen Rückverfolgbarkeit der Charge hat.

Our welding wire is manufactured in our ISO 9001:2015 certified facilities in the U.S., Canada, and the UK.

Welding Wire for MIG TIG & SAW Welding

Schweißarten

We manufacture welding wire suitable for different welding practices including:

- MIG

Metal Inert Gas, also known as Gas Metal Arc Welding (GMAW)

- WIG

Tungsten Inert Gas, or Gas Tungsten Arc Welding (GTAW)

- SAH

Visit our Informationsseite zu Schweißarten to learn more.

Schweißverfahren

CWI Generation4 ™ Stainless Steel and Nickel Welding wire alloys can be used with many different joint styles and welding processes. Once the weld joint style, the filler material, and the process has been identified, a proper welding procedure can be identified.

Some factors to consider when choosing your welding wire and procedure are:

- Voltage

- Amperage (Current)

- Gas (Atmosphere)

Visit our Seite Empfohlene Schweißverfahren um detaillierte Informationen zu Spannung, Stromstärke (Strom) und Gas (Atmosphäre) zu finden, die mit unseren Schweißzusätzen in Ihrer spezifischen Schweißanwendung verwendet werden sollen.

Legierungen

Our welding wire is available in a multitude of stainless and nickel–based alloys, including:

- ER209

- ER218

- 309LMo

- ER409NB

- Specialty Nickel Chrome Alloys:

– 276

– 622

– 625

– 686

– Alloy 59

Branchen

We manufacture welding wire that is suitable for a variety of industries where the highest levels of quality and safety are required. Our welding wire consumables are used in Branchen like:

- Öl und Gas

- Nahrungsmittel und Getränke

- Automobil

- Verteidigung

- Nuklear

- Energie

- Konstruktion

- Marine

- Rail

- Structural Engineering

- Herstellung

Anwendungen

For every welding application, Central Wire has a Generation4™ alloy that can meet your requirements. Some of the most common applications are:

- Tankherstellung

- Auflage/Verkleidung

- Chemische Verarbeitung

- Rohre

- Wasserturbinen

- Schalldämpfer

- Pumpen und Ventile

- Kryo-Schweißen

- Boats and Barrages

- Fuel Lines

- Engine Parts

- Tubing

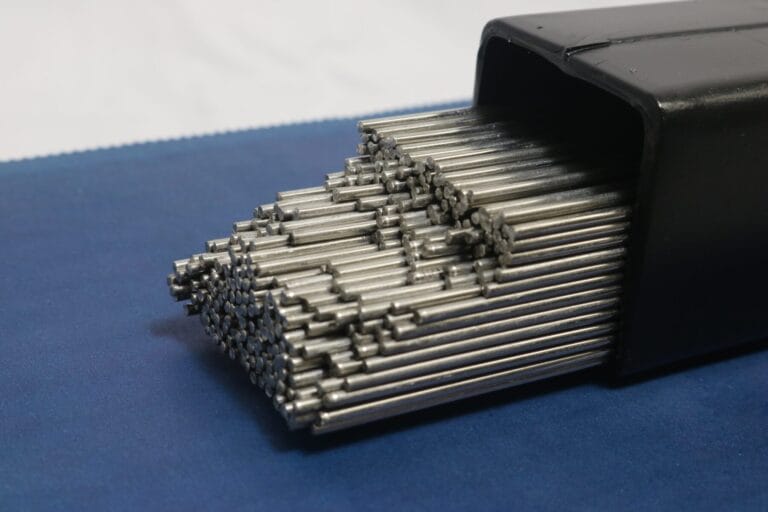

Packaging

No matter your packaging needs, Central Wire can provide customized solutions to fit your applications. Multiple packaging and shipping options are available from our facilities in the US, Canada, and the UK, including:

- Rollen

- Spulen

- Schlagzeug/Drumpacks

- Rohre

- White Labeling

Literature

We have a wide range of literature to assist you with your welding wire purchase. Our literature includes:

- Schweißdraht aus Nickellegierungen SDB

- Schweißen Gen4 2020 Broschüre

- Edelstahl-Schweißdraht SDB (Französisch)