CWI Generation4™ Welding Wires are designed for use in many different welding processes. The three most common types of welding used with our stainless steel and nickel welding alloys are Tungsten Inert Gas (TIG), Metal Inert Gas (MIG) and Submerged-Arc Welding (SAW). To ensure that you select the proper welding consumable alloy to work with your welding process, a brief description of each process is listed below. If you need further information on the specific welding parameters (Diameter, Voltage, Amperage, and Gas) recommended for each CWI Generation4 ™ Alloy, visit our recommended welding procedures page.

TUNGSTEN INERT GAS (TIG) WELDING

Aussi connu sous le nom Soudage à l'arc sous gaz tungstène (GTAW), TIG welding uses a tungsten electrode, a filler metal and an inert shielding gas (such as argon or helium) during the welding process. This method requires a highly skilled welder, as the manual technique requires two hands to utilize the equipment and apply the filler metal to create the weld joint. TIG welding is typically used with stainless steels and non-ferrous metals, on thinner section of metal, and provides the welder greater control over the properties of the weld versus other similar processes. It has the disadvantage of being relatively slow due to it’s complexity and multi part process.

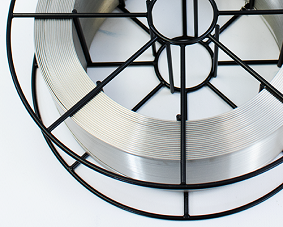

METAL INERT GAS (MIG) WELDING

Aussi connu sous le nom Soudage à l'arc sous gaz et métal (GMAW), the MIG welding process employs a welding gun, a power supply, an electrode (alloy wire) and a shielding gas. The welding procedure is uncomplicated, with the welding gun bringing all the required components (power, filler metal, shielding gas) together at the weld point. Compared to other methods, training for MIG welding requires less time to develop a usable skill level in the field. It is the preferred welding method in most industrial applications, and can be easily adapted to automation if required. Issues with dross and porosity of welds can affect the quality of the finished welds, so additional scrutiny of materials and cleanliness is required.

SUBMERGED ARC (SAW) WELDING

Souvent appelé Soudage à l'arc sous-marin, le procédé de soudage SAW est principalement une méthode de soudage automatisée qui isole la zone d'arc sous (sous) la surface d'un flux fondu, éliminant ainsi la contamination atmosphérique. Le processus utilise une alimentation continue de fil de soudage consommable dans une combinaison fil/alliage simple ou multiple. SAW a l'avantage d'un taux de dépôt élevé et d'une pénétration profonde de la soudure, ce qui permet un taux de soudage élevé en pieds/min. Il permet également des soudures en un seul passage avec un matériau plus épais. Le SAW est limité par le plan de l'opération de soudage (les soudures droites sont préférées) et peut nécessiter une étape supplémentaire d'élimination du laitier.

Diamètres de fil par type de soudure

| Diamètres MIG (GMAW) | Diamètres TIG (GTAW) | Diamètres SUB ARC (SAW) | |||

|---|---|---|---|---|---|

| Impérial dans. | Métrique mm | Impérial dans. | Métrique mm | Impérial dans. | Métrique mm |

| 0,023 | 0,6 | 1/16 | 1.6 | 5/64 | 2 |

| 0,030 | 0,8 | 3/32 | 2.4 | 3/32 | 2.4 |

| 0,035 | 0,9 | 1/8 | 3.2 | 1/8 | 3.2 |

| 0,045 | 1.14 | 5/32 | 4.0 | 5/32 | 4.0 |

| 0,047 | 1.2 | 3/16 | 4.8 | ||

| 1/16 | 1.6 | ||||