Oil and Gas Efficiency

In this industry’s various filtration and mass transfer applications, temperature changes, chemicals, and other challenges can wear products down. Investing in the right materials ensures quality production and limits the need for repairs.

Below you can see our product lines that cater to the industry, and the applications of our products in oil and gas.

Lignes de produits

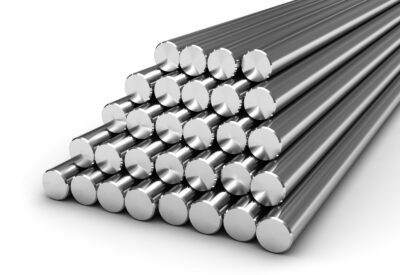

Premium stainless steel and nickel bar stock manufactured up to 0.750” to customer specifications. Highly customizable for many end-use applications and mission critical industries.

Cold heading wire is available in stainless, nickel, and copper base alloys. Quality raw material for use as fasteners, blind rivets, screws and bolts.

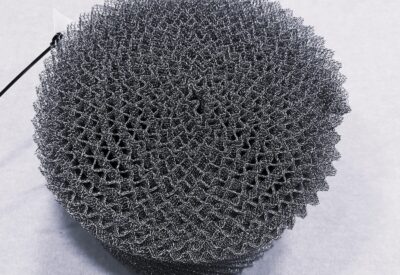

Custom demister pads manufactured in shapes including round, rectangle, ring and custom. Strong grid structure and ductility capabilities allow for consistent mist elimination.

Fil fin de haute qualité produit dans des tailles allant de 0,001" à 0,032", avec des tailles personnalisées disponibles sur demande. TLes empereurs vont du recuit doux au revenu de printemps.

Wire filter mesh made from individual wires that are interlaced, or knitted, together. Loops are strategically woven to be able to move and stretch, with flexibility and durability to handle harsh applications.

Structured and random packing products perfect for robust mass transfer applications. Structured packing available in gauze, knitted, grid and sheet metal forms. Random packing available in materials like metal, plastic and ceramic.

Available in stainless, duplex, nickel, copper, brass and carbon alloys, our shape wire is custom manufactured in house to fit specific customer needs. Les tailles de fils profilés que nous proposons sont les suivantes 1.25mm² à 150mm ² CSA (Cross Sectional Area).

Corrosion resistant spring wire comes in stainless steel and nickel alloys, boasting excellent coiling ability at high speeds needed no additional lubricant. Manufactured in sizes from 0.022” to 0.625”.

Manufactured to provide a continuous, weld-free, bright finish wireline available in a variety of lengths up to 40,000 feet. Corrosion resistant lines designed to go downhole in sour and sweet environments.

Welding wire produced for various techniques including MIG, TIG and SAW welding. Available in stainless and nickel-based alloys.

The oil and gas industry presents unique challenges, requiring materials with chemical and corrosion resistance to go along with consistent performance.

Let’s look at some of the applications of our products in the oil and gas industry.

Applications des produits

Downhole Operations

Notre GD™ – SUPA® slicklines can handle all the harshest oil and gas conditions, both on-shore and off-shore. Heavy breaking loads allow for heavy downhole performance. Multiple alloy options allow adaptably to different temperatures and applications. Our slicklines can be used for well measuring lines, in downhole applications and as electro-mechanical cable.

Mass Transfer

CWI’s structured and random packing product line excels in mass transfer applications in oil and gas columns. Reducing pressure drops, handling low and high liquid loads, and size and shape variety are just a few reasons to choose our packing solutions. Both structured and random packing increase surface area, thus facilitating more liquid-vapor contact within columns.

Liquid-Gas Filtration

Our knitted wire mesh and demister pads create excellent liquid-gas filtration, especially in the oil and gas industry. Custom manufacturing, flexibility and strong metal alloys ensure successful filtration remains consistent in harsh conditions.

Vessel Repair

Excessive repairs or material replacement is an obstacle in many industries, including oil and gas. Quality welds using the correct techniques and welding wire keeps oil and gas vessels from wearing down or breaking in robust filtration applications.