Enhanced driving comfort and safety on the roads are crucial factors in technological advancements and compliance in the Automoción industry. Mandating manufacturing processes and vehicle features help to provide some consistency across every new car being put on the road.

With the concerns in this industry ranging from how long a car will last to handling harsh weather conditions, compliance standards are in place to improve the driving experience while keeping drivers safe.

Continue reading below to learn about some of the trends and developments regarding Automotive compliance in manufacturing, and what product lines we manufacture that cater to safe and smooth Automotive operation.

Cybersecurity

Innovations in connected and high-tech vehicles are offering an unprecedented driving experience for consumers, and new levels or revenue for Automotive manufacturers. However, with the Automotive ecosystem becoming far more digital, there are cybersecurity measures required to ensure the protection of data and safety.

The National Highway Traffic Safety Administration (NHTSA), with understanding of the vulnerability to hacking with such digitalized vehicles, released guidelines on the Best Practices for Modern Vehicles. Some of the principal functions of the updated guidelines are:

- Risk Based Priorities for Protection of Safety-Critical Vehicle Systems and Sensitive Information

- Timely Detection and Rapid Response to Potential Threats

- Rapid Recovery if Attacks Occur

- Methods for Accelerating the Adoption of Lessons Across the Industry

Increased digitalization and technological advancements in vehicles are changing the driving experience for many consumers, and these regulations help to ensure the positives can be achieved in a safe manner.

Mobility Safety: EVs, Autonomous Vehicles, and Other Innovations

Trends and innovations in modern vehicles, from electric cars to autonomous vehicles, have created a need for new regulations and compliance requirements to ensure safety. For accurate data collection the Society of Automotive Engineers (SAE) created a six-level classification system with 0 being a vehicle where a driver is fully responsible for driving tasks, and 5 being a fully autonomous driving experience.

One of the main requirements is ensuring accident reporting for vehicles equipped with level 2-5 autonomy. This helps to offer consumers full transparency about the decision to purchase and drive an autonomous vehicle. This research takes into account weather conditions, road congestion and more to create more accurate data.

Electric Vehicle compliance involves everything from the manufacturing of the cars, to ensuring the power grid can handle charging requirements as popularity grows. One of the main EV-exclusive manufacturing requirements is the minimum sound for hybrid and electric cars, to ensure safety for pedestrians and other drivers.

Autonomous and Electric Vehicles are rigorously tested for safety and performance, but data recorded on the roads helps to create transparency and give manufacturers and consumers a better understanding of the way these vehicles perform.

Defects, Repairs, and Vehicle Safety

Compliance standards for vehicles don’t just consider manufacturing but also defect reporting and repair requirements. The lifespan of a car includes various repairs and inspections, and these must be conducted safely and thoroughly, with accurate reporting.

Transport Canada for example has regulations where they are required to be notified if a company becomes notified of safety defects or non-compliance with safe manufacturing standards. These issues are then critically shared with consumers who can have issues repaired or have their vehicle exchanged for one which follows road safety and compliance standards.

Requirements for safe driving and manufacturing in the Motor Vehicle Safety Act cover and regulate three main sectors: vehicles, tires, and child car seats. These acts apply to people and companies that import, distribute and manufacture vehicles. This mandates safe and consistent vehicle manufacturing and ensures tires and car seats are up to a certain standard, protecting every passenger in the vehicle.

Central Wire’s Automotive Product Capabilities

Our full gama of products means we serve various industries with parts for repair specialists, manufacturers and more. Check out some of our Automotive capabilities below, from small connective parts to long-lasting repairs.

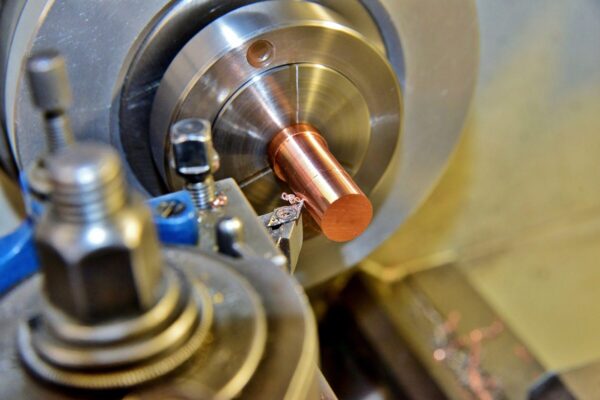

Specialty Bar Stock and CNC Machined Parts

Our custom manufacturing capabilities are showcased in our Specialty Stock de bar y Mecanizado CNC product lines. With our centerless grinding, milling, turning, and other custom machining processes, we can meet the tight tolerances required to promote safety and compliance in this industry. Common applications include engine components, shafts, axles, fasteners, and other small connective parts that help a vehicle last.

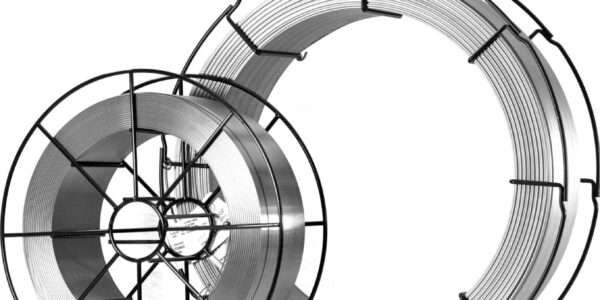

Generation4™ Welding Wire

As a manufacturer of Stainless, Nickel, and Specialty Nickel-Chrome Welding Wire, we can meet the specifications of countless industries, including Automotive. Our Gen4™ line is suitable for MIG, TIG, and SAW Welding processes, serving a variety of Automotive Welding applications including body panels, underbody subframe, engine mount, front grille, and more.

A Trusted Supplier: The CWI Advantage

With 60 years of manufacturing experience, and Domestic product capabilities in Canada, the USA and the UK, Central Wire is your trusted source for reliable products that are quality tested for durable industry performance.

Check out our Quality & Testing y Capacidad de fabricación pages for more information on the full scope of our product offerings and rigorous testing procedures.

To unlock Central Wire’s versatile capabilities, in Automotive and beyond, Request a Quote with us today!