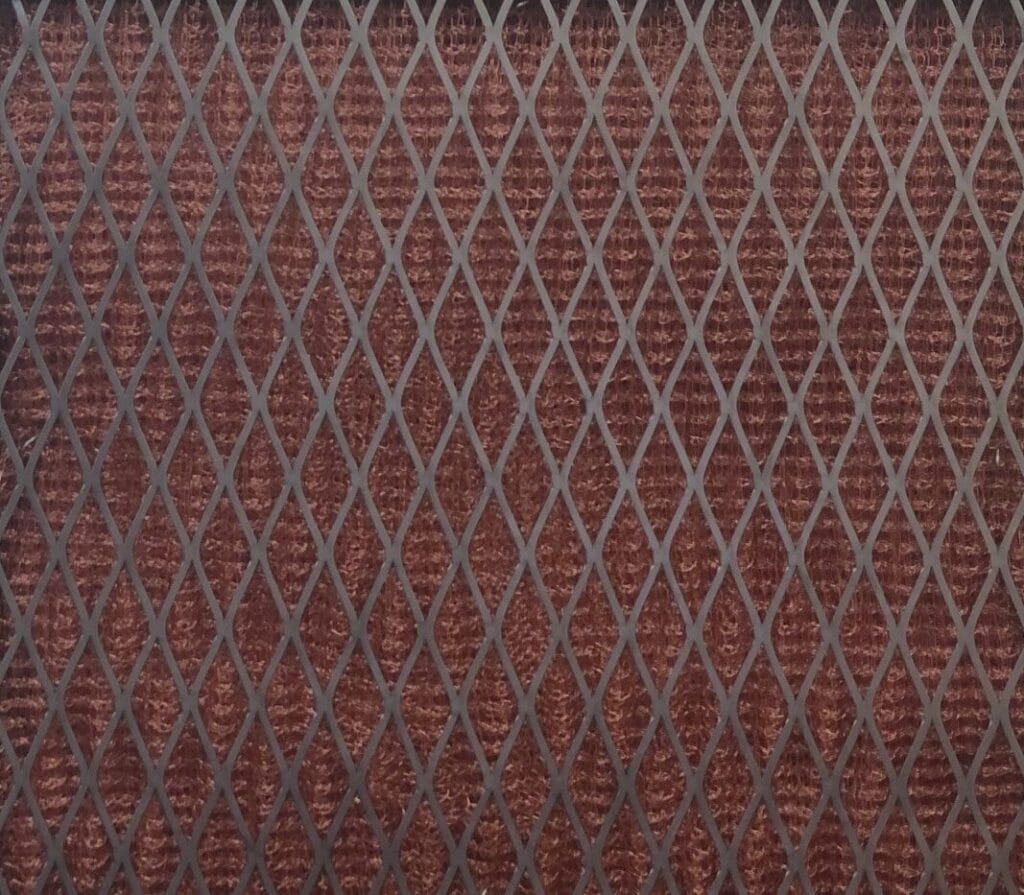

Applications of Our Copper Wire Mesh

One of the most versatile alloys that we produce is copper. Possessing high tensile strength, high ductility, and good corrosion resistance, copper is built to withstand the harsh conditions of the industries we serve.

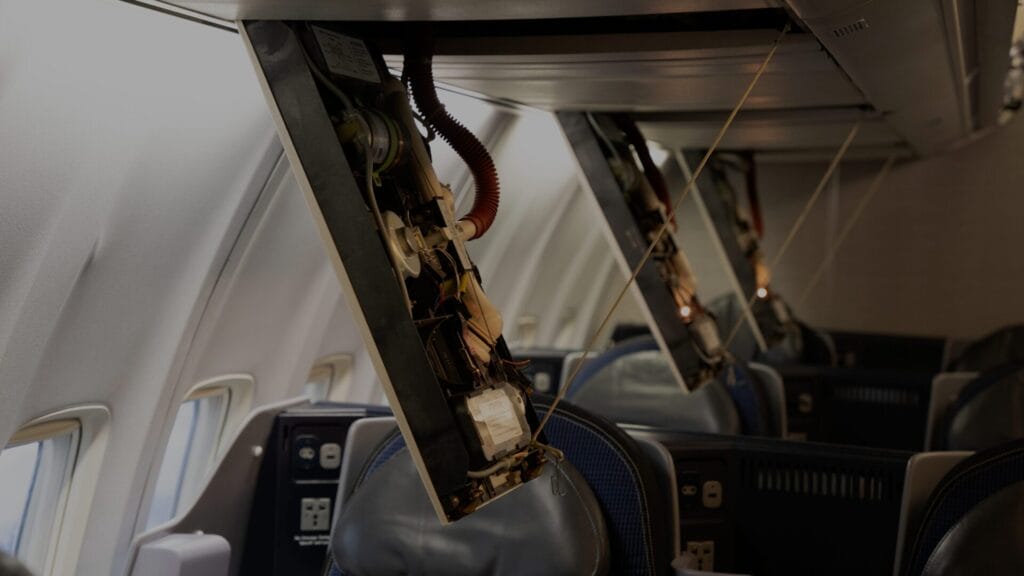

Balancing Flexibility, Strength and Fatigue in Aircraft Cable

The Aerospace applications that use our Aircraft Cable are essential, from flight control to emergency control systems.

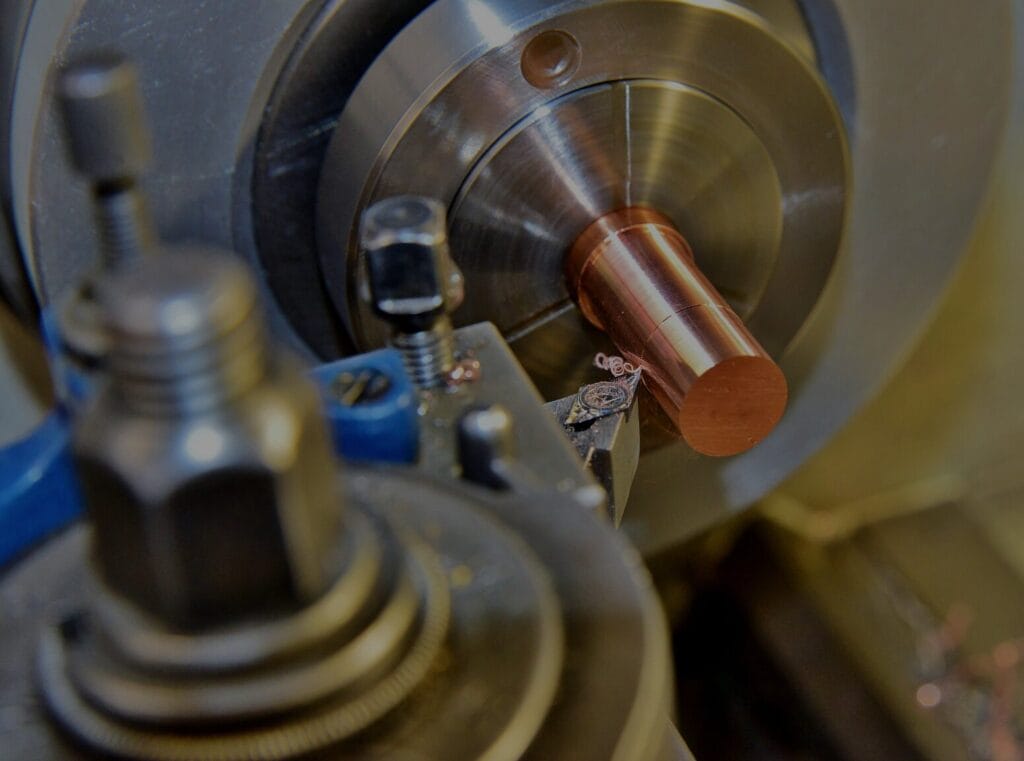

Our Many CNC Machines and their Capabilities

Specific machinery is required to create the right product to serve our customer base with short lead times.

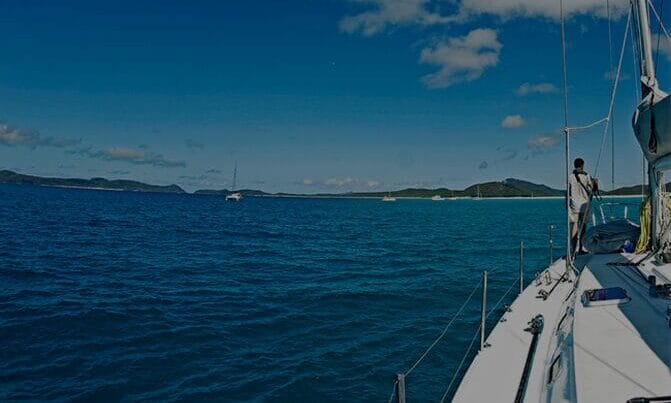

Our Cable Products in the Marine Industry

Having a way to meet risks & challenges is essential for marine cable products, just as much as it is for the captain of a ship.

How Does Your Beer Make it to the Table?

In a world where home brewing equipment and other machinery have seemingly simplified the beer making process, there are still challenges and demands that must be met to ensure the process works out.

Car Restoration and Welding Techniques

Beyond sourcing parts and deciding on paint, interior design and other aesthetic features, one of the main tasks is welding repairs. There are plenty of body shops capable of doing this, but many car restoration jobs are preferably done by the individual.

What is Seismic Bracing?

Loos & Co. Seismic Bracing products can help prevent much of the damage caused by earthquakes, that some home and business owners may not think about.

CWI Coatings for Every Application

High quality metals and alloys promote strength, durability and consistent performance. However, they can be made to last even longer with specialty coatings.

Loos Precision Products Offer Machined Excellence

From aerospace to medical, and industrial to commercial, Loos Precision Products offers innovative solutions for custom-machined hardware and accessories, delivered on time and to your specified requirements.

Central Wire Manufactures Bar Stock For Aerospace and Beyond

Turning premium bar stock metals into fasteners, engine components, fasteners and more is made easy with our quality manufacturing.

Common Questions About Custom Cable Assemblies

Cable assemblies can be as simple or complex as you need them to be. Whatever specifications or customizations you require, we can provide them. It’s what we do!

Where is Fine Wire Used?

Picture this – a wire so thin that it’s almost invisible, yet strong enough to help shape the future of technology in fields as complex as aerospace and medicine – that’s the power of fine wire.

Stoffaustausch bei strukturierter und zufälliger Packung

Both structured and random packing provide unique advantages in the oil and gas industry, as well as other industries. Refinery towers and dehydration columns require the precise performance that packing solutions provide. Enhancing your oil and gas operations is made easy with structured and random packing products.

Wie wählt man Zurrdraht-Materialsorten

There has never been a time period as electronically driven as we are in right now. This means more people relying on high-speed telephone service and that the need for preventing or reducing power outages is more prevalent than ever before. Welcome the unsung hero – Lashing Wire.

Wie Widerstandsdrahtlegierungen die Hitze bringen

One struggle for some of our customers is finding the right product to handle high temperature environments. Whether this be a home appliance with heating elements or electrical applications where conductivity is the key, resistance wire plays an essential role in your project’s needs.

Bewältigung der Herausforderungen beim Schweißen von rostfreiem Stahl

Welding presents very unique challenges, many of which revolve around using the right material so that your weld lasts and maintains over a long period of time. One material that can present some challenges is welding using stainless steel.

Hochspannungsfederdraht für jede Anwendung

Springs are a universal solution for a variety of modern products ranging from the high-tension performance requirements of heavy equipment and transportation to the rapid flexing and space constraints in electronics and other small objects.

Prüfung mit fluoreszierendem Eindringmittel: Der Defekt-Detektiv

Nondestructive Testing (NDT) is a group of quality control examination processes used in various mission-critical industries. From aerospace to medical, evaluating materials without compromising the structural integrity, before they go into end-use, is vital.

Der Kampf von Kupferdraht gegen Mikroben und Bakterien

Multiple industries use copper wire for its conductivity and corrosion resistance. However, did you know that many businesses also choose copper for its antibacterial properties?

Legierung MP35N®: Vielseitigkeit, Stärke, Widerstandsfähigkeit

When searching for metal alloys to deploy in crucial applications, reliability and strength are the qualities to search for. MP35N® is an alloy that not only possesses these traits but can handle harsh environments effectively.

CWI: Dienstleister für die gesamte Öl- und Gasindustrie

The oil and gas industry can be taxing, on not just workers but on products as well. Any materials being used need the appropriate qualities to withstand the harsh conditions of this industry.

Beseitigung von Nebel und Filtration: Die Rolle von Demister-Pads

Alongside knitted mesh in the Tech-Mesh™ product line, demister pads, also known as mist eliminators, are one of the most versatile and influential pieces of filtration equipment.

Investieren Sie in die richtigen Kabelkonfektionen?

Are You Investing in the Right Cable Assemblies & do you know which one is right for your application? Let’s dive in and find out!

Was ist der Unterschied zwischen MIG- und WIG-Schweißen?

Chances are, you’ve crossed paths with MIG and TIG welding in conversations about metalwork. But what are the core differences between these two types of welding?