Learn about our high-performance Nickel-Chromium Alloy, Inconel® X750. Used Primarily in Aerospace & the Oil & Gas Industry.

MP35N® Overview

MP35N® is a multi-phase, nickel-cobalt based alloy that has a unique combination of ultrahigh tensile strength, good

toughness and excellent corrosion resistance. It maintains its toughness, ductility, and corrosion resistance in a range of environments from cryogenic temperatures up to 850°F (454°C) and is virtually immune to crevice and stress corrosion. MP35N® is highly resistant to sulfide stress corrosion cracking and provides excellent performance in the most demanding sour well environments.

MP35N® Nominal Composition

| C | Minnesota | PAG | S | Si | cr | Ni | Mes | ti | Fe | Co | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| mínimo | 19.0 | 33.0 | 9.0 | ||||||||

| máx. | 0.025 | 0.15 | 0.015 | 0.01 | 0.15 | 21.0 | 37.0 | 10.5 | 1.0 | 1.0 | balance |

Aplicaciones

Due to Alloy MP35N®’s high combination of strength, high modulus values, and good corrosion resistance, Alloy MP35N® is used in:

- Dispositivos médicos

- Productos dentales

- Barras de torsión

- Aeroespacial y Defensa

- Sujetadores

- Motores

- Gas de petróleo

- Carcasas de presión

- focas

Physical Properties

| At 70°F | At 20°C | |

|---|---|---|

| Density | 0.304 lb/in³ | 8.42 g/cm³ |

| Modulus of Elasticity (E) | 33.8 x 10³ ksi | 233 GPa |

| Modulus of Rigidity (G) | 12.1 x 10³ ksi | 83.4 GPa |

| Coefficient of Expansion | 8.2 microinches/in.-°F (70-600°F) | 14.8 x μm/m°C (20-300°C) |

| Electrical Resistivity | 40.6 μ ohm.in | 103 μ ohm.cm |

| Thermal Conductivity | 78 Btu-in./ft.²hr.-°F | 11.2 W/m-K |

Typical Mechanical Properties - Spring Applications

| Condition | Heat Treatment | Tensile Strength | Suggested Operating Conditions |

|---|---|---|---|

| Solution Heat Treated | 1900 – 1925°F (1038–1052°C) for 4 to 8 hours | 115 – 140 ksi (793 – 965 MPa) |

-300°F to 800°F (-184°C to 427°C) |

| Spring Temper | 220 – 280 ksi (1517 – 1931 MPa) |

-300°F to 800°F (-184°C to 427°C) |

|

| Spring Temper + Aged | After spring coiling Age: 1200°F (649°C) minimum for 4 hours |

240 – 300 ksi (1655 – 2068 MPa) |

-300°F to 800°F (-184°C to 427°C) |

Estándares de la industria

El uso comercial de la aleación se rige por estándares industriales como: AMS 5844, 5845 (capaz), ASTM F562, NACE MR0175 (ISO 15156-3), NACE MR0103 (ISO 17945)

El uso aeroespacial se proporciona a través de AMS 5678G, que controla aún más el material con pruebas de calificación adicionales en la microestructura final del cable trefilado.

Available Specifications

| Wire & Bar | AMS 5844, 5845 (capable), ASTM F562, NACE MR0175 (ISO 15156-3), NACE MR0103 (ISO 17945) |

Microstructual Aspects

MP35N® has a face centered cubic (FCC) microstructure in the annealed condition. This is like other nickel and cobalt-based alloys. The primary strengthening mechanism is the partial transformation of the FCC structure to a hexagonal close-packed (HCP) structure. The FCC phase is stable above 1200°F, whereas the HCP structure is stable below 800°F.

However, the transformation from FCC to HCP cannot occur by temperature alone and requires mechanical deformation. Age hardening without mechanically deforming the materials to form the HCP structure has little effect because the cobalt-molybdenum phase forms at the interfaces between HCP platelets and the FCC matrix. Yield strengths greater than 260 psi (1793 MPa) are possible in the high-strength condition.

MP35N® Alloy Spotlight Video

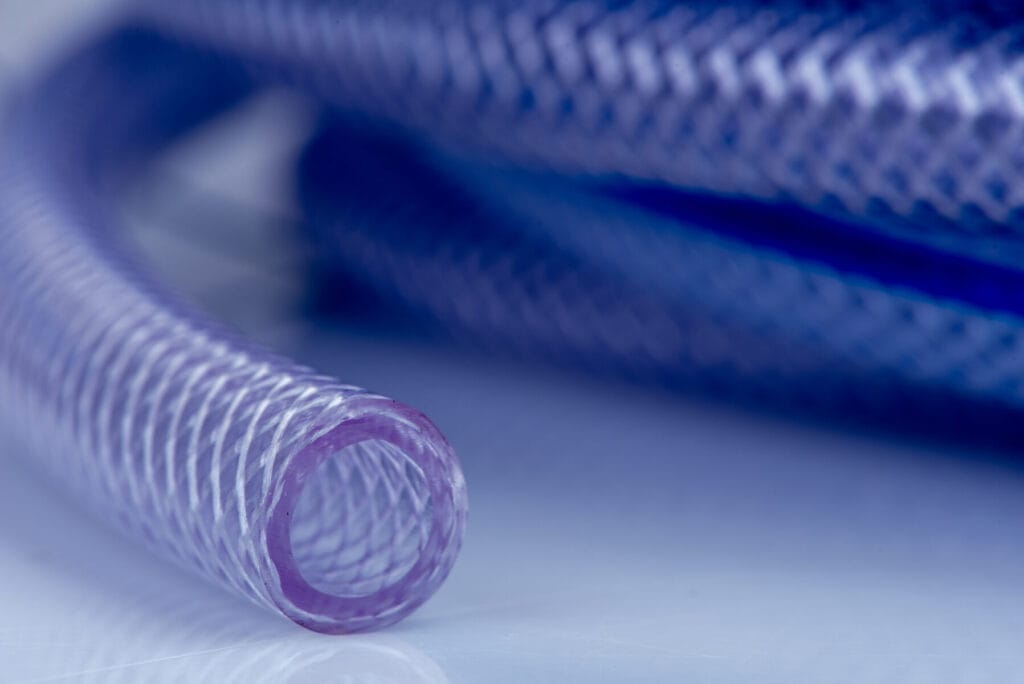

Opciones de embalaje

- Bobina

- Carretes

- Barras

- Embalaje personalizado disponible