Aerospace manufacturing requires diligence, precision and quality control to meet mission critical standards, and ensure efficiency and safety. As a manufacturer of custom, premium products that support this industry, we understand the requirements that provide consistent, quality production across Aerospace and Defense.

The introduction and implementation of automation in part manufacturing and aircraft assembly reduces human error and maintains ultra tight tolerances and specifications in critical components. Workplace injury risk from repetitive motion and manual material handling are also significantly decreased with the use of automation.

Learn more below about how technological advancements in automated manufacturing are aiding in maintaining quality and safety in Aerospace.

Automation in Aircraft Assembly & Manufacturing

Along with strict requirements for manufacturing precision, mass production industries such as Aerospace also create risks of manual labor related injury. Many of the tasks in the manufacturing process pose hazards such as handling heavy components, working at heights, and repetitive motions. The use of automated systems to assemble and move large aircraft components helps to protect workers and lower their risk of injury.

The complex, precise and time-sensitive supply chain in this industry demands highly efficient manufacturing that still meets industry specifications. The use of robotic arms and other automated systems can speed up production, while reducing potential human error. Even the smallest imbalances or deviation in aircraft dimensions can lead to critical failure, putting high importance on precision.

Examples of the use of automation in this industry to protect workers, improve efficiency, and maximize precision include robotic arms that are used to assemble large structures like fuselages and wings, and AGVs (Automated Guided Vehicles) that are used to transport large components within a facility.

Limiting the manual requirements of repetitive and strenuous assembly tasks in this industry helps to limit the risk of worker injury while enhancing precision in an industry that requires every step to be exact.

Automated Fluid Dispensing Systems

Another major trend in the shift to Aerospace manufacturing automation is the increased use of automated fluid dispensing systems. Helpful in meeting precision and consistency standards, these systems apply a range of fluids including adhesives, sealants and lubricants with meticulous accuracy.

Using automated systems for fluid dispensing is crucial to ensuring the integrity of critical Aerospace components, especially those that are exposed to extreme conditions. The benefits of automating this process include:

- Consistent application process, meeting quality standards and creating a uniform coating.

- Reduced need to handle hazardous materials, improving worker safety.

- Higher production rates due to the speed and efficiency of automated dispensing.

With time-sensitive deadlines placing unique pressure on the Aerospace supply chain, the use of automated fluid dispensing systems maximizes efficiency without sacrificing precision. These adhesives and coatings are crucial to aircraft performance and durability, making this a critical innovation in Aerospace manufacturing.

Custom Engineered Aerospace Components

Using high quality raw materials is crucial in Aerospace manufacturing, as is meeting tight tolerances. Aircraft components must be engineered to precise project requirements to ensure high performance in mission critical applications. With automation and robotics becoming more prevalent in aircraft part manufacturing, custom components are being manufactured more efficiently and precisely than ever before.

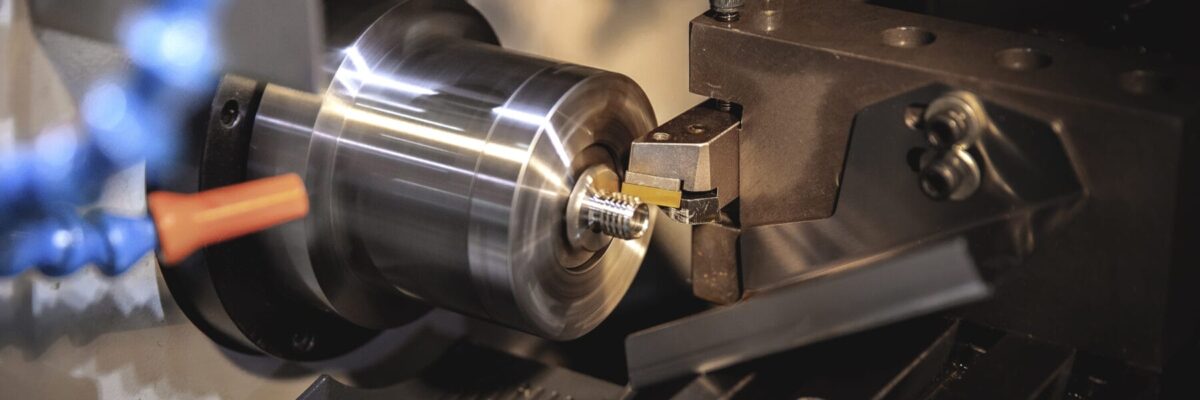

One example is CNC Machining, which is one of our many product capabilities that serve this industry. By using CAD (computer aided design) and CAM (computer aided manufacturing) files, precise product data is created. From there, our CNC machines use the precise direction, including size and shape requirements, speed, voltage, and more to make cuts and produce the perfect product.

These custom components, manufactured from military grade alloys, serve various Aerospace applications, including:

- Fasteners, Bolts, Screws, Nuts

- Engine Components

- Landing Gear Components

Our Product Capabilities Serving Mission Critical Applications

Our multi-faceted manufacturing capabilities have made us a globally recognized manufacturer in the Aerospace industry. Below are some of our trusted product capabilities relied on by some of the biggest Aerospace corporations.

Critical Cable Assemblies

The Aerospace and Military sectors possess stringent standards for military grade materials and a need for quick lead times that can only be met with the highest quality products. With the industry’s largest Assembly inventory, we can meet all of your project needs with the short lead times that keep your business running smoothly.

Our Bulk Cable (bare & coated) and Hardware & Fitting selection means your Aerospace Assemblies can be fully customized to your precise needs. We can also cross reference all NSN’s, part numbers, or drawing numbers from any design activity. This includes Army, Navy, and OEM manufacturers.

To learn more about why our Assemblies are trusted by so many Aerospace corporations, or to kickstart your next project with us, visit our product page below!

Custom Components – CNC & Bar Stock

For the critical components that keep everything together, from fasteners to bolts and screws, our custom part manufacturing capabilities offer unmatched quality and precision. Our previously mentioned CNC Milling and Turning capabilities can maintain tolerances as small as .0001”, while also using rigorous testing methods to ensure quality and detect potential flaws.

We also offer Centerless Ground Bar Stock products which can be manufactured up to 0.750” to customer specifications. Our state-of-the-art equipment allows for superior quality control, precise tolerances, and an improved surface finish. This product line primarily uses DFARS compliant Stainless Steel and Nickel alloys, meeting the mission critical requirements of the Aerospace industry.

Our meticulous manufacturing process and vast raw material capabilities make us an unmatched source for quality Aerospace components. Learn about these two products and their full range of capabilities below!

Investing in our Aerospace Expertise

With years of experience, industry-leading machine capabilities and expertise, our Aerospace product offerings are trusted by many for durable, mission critical performance. Our long list of Military Specifications and Federal Classifications support the quality and precision of our manufacturing.

Learn more about our approvals, certifications, domestic manufacturing and more on our website today!