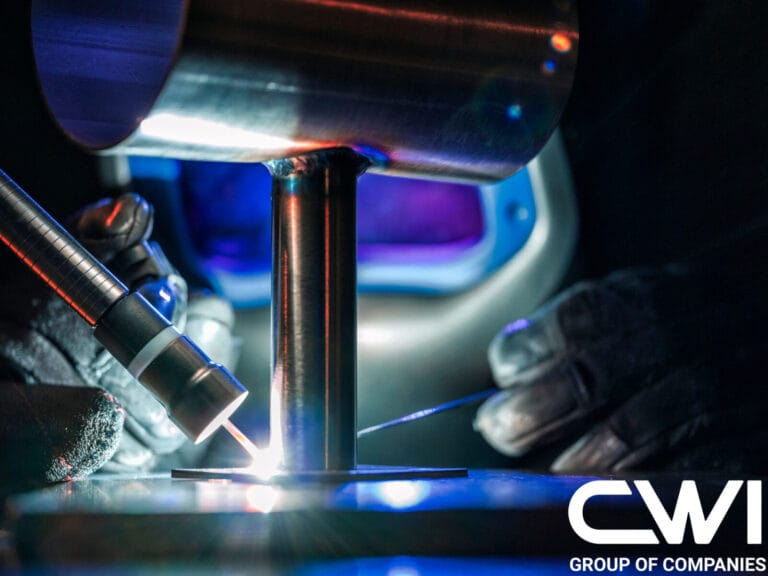

Discover our specialized Welding Wire suitable for MIG, TIG, & SAW welds. Designed for superior strength and adaptability.

Our welding wire is manufactured to your exact specifications, fulfilling a variety of filler needs for many technical processes. Whether you’re a fabricator or a wholesaler, Central Wire manufactures the MIG, TIG, and SAW welding wire you need.

All Welding products are supplied with a certificate of conformance stating physical and mechanical properties including alloy chemistry. Every welding product is manufactured to have its own unique lot identification number for full lot traceability.

Our welding wire is manufactured in our ISO 9001:2015 certified facilities in the U.S., Canada, and the UK.

Welding Wire for MIG TIG & SAW Welding

Welding Types

We manufacture welding wire suitable for different welding practices including:

- MIG

Metal Inert Gas, also known as Gas Metal Arc Welding (GMAW)

- TIG

Tungsten Inert Gas, or Gas Tungsten Arc Welding (GTAW)

- SAW

Visit our Welding Types Information page to learn more.

Welding Procedures

CWI Generation4 ™ Stainless Steel and Nickel Welding wire alloys can be used with many different joint styles and welding processes. Once the weld joint style, the filler material, and the process has been identified, a proper welding procedure can be identified.

Some factors to consider when choosing your welding wire and procedure are:

- Voltage

- Amperage (Current)

- Gas (Atmosphere)

Visit our Recommended Welding Procedures page to find detailed information on the voltage, amperage (current), and gas (atmosphere) to be used with our welding consumables in your specific welding application.

Leghe

Our welding wire is available in a multitude of inossidabile e nichel-based alloys, including:

- ER209

- ER218

- 309LMo

- ER409NB

- Specialty Nickel Chrome Alloys:

– 276

– 622

– 625

– 686

– Alloy 59

Industrie

We manufacture welding wire that is suitable for a variety of industries where the highest levels of quality and safety are required. Our welding wire consumables are used in industries like:

- Petrolio e gas

- Food and Beverage

- Automotive

- Defense

- Nuclear

- Energia

- Costruzione

- Marina

- Rail

- Structural Engineering

- Manufacturing

Applicazioni

For every welding application, Central Wire has a Generation4™ alloy that can meet your requirements. Some of the most common applications are:

- Tank Fabrication

- Overlay/Cladding

- Chemical Processing

- Pipes

- Hydro Turbines

- Mufflers

- Pumps and Valves

- Cryogenic Welding

- Boats and Barrages

- Fuel Lines

- Engine Parts

- Tubing

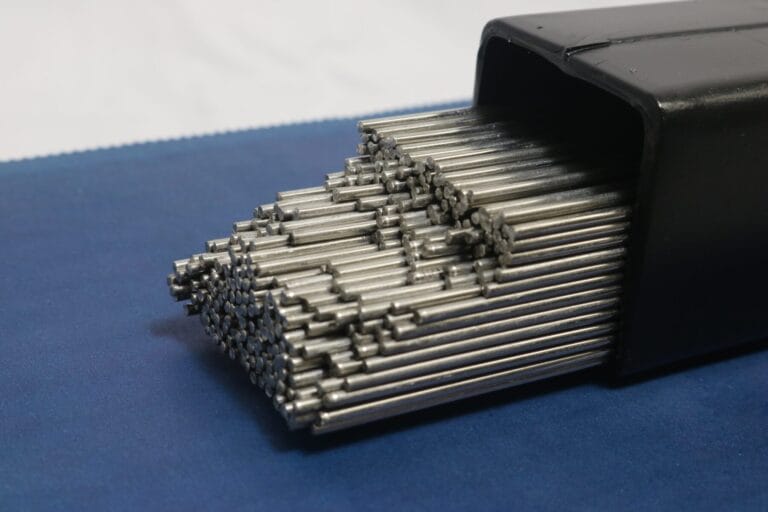

Imballaggio

No matter your packaging needs, Central Wire can provide customized solutions to fit your applications. Multiple packaging and shipping options are available from our facilities in the US, Canada, and the UK, including:

- Mulinelli

- Bobine

- Drums/Drum Packs

- Tubi

- White Labeling

Literature

We have a wide range of literature to assist you with your welding wire purchase. Our literature includes:

- Stainless Steel Welding Wire SDS

- Filo per saldatura in leghe di nichel SDS

- Stainless Steel Welding Wire SDS (French)