As a custom manufacturer that serves various industries, we understand the need for different metal alloys depending on corrosion risks, temperature, moisture, and other variables present in different applications. However, it may not be clear to some customers when to use which of our alloys, and what strengths and weaknesses they possess.

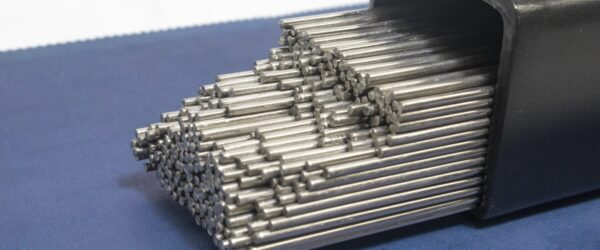

Two of our most versatile alloy series are Inconel® and Monel®, both falling under our Nickel Specialty Alloy category. Although they fall under the same group, the different chemical compositions lead to different strengths and applications for both groups.

Continue reading to learn about what makes both Inconel® and Monel® so effective in their respective industries and end-use applications.

Chemical Composition Differences

As mentioned, Inconel® and Monel® are both a part of our Nickel Specialty Alloy category, however their exact chemical composition does differ. Monel® alloys are nickel-copper based, while our Inconel® alloys are nickel-chromium.

Nickel-copper based alloys are especially great for corrosion resistance, with notable strengths of handling saltwater corrosion, as well as sulfuric and other acids.

Nickel-chromium based alloys are more known for oxidation resistance and handling extreme temperatures, so they are often applied in industries with different gases present and large temperature variances.

Industries & Applications

Inconel®: The applications best suited to the strengths of Inconel® alloys include aircraft parts, oil and gas extraction, heating elements in kitchens, and pharmaceutical applications.

Monel®: The applications best suited to the strengths of Monel® alloys include oil refineries, chemical processing, coastal structures, and many applications within the Marine industry.

Alliages de spécialité

Under both of these alloy series, there are specific alloys designed to handle certain conditions and challenges. Below are some of the most prevalent Inconel® and Monel® alloys.

Inconel® X-750

One of our highest performance alloys, X-750 is an austenitic alloy that is made precipitation-hardenable by the addition of aluminum and titanium. It can offer great resistance to corrosion and oxidation, along with high tensile and creep-rupture properties at high temperatures.

The workability of this alloy is excellent, including machinability and welding. It offers elevated temperature strength properties to 1300ºF and oxidation resistance to 1800ºF. X-750 is also resistant to a variety of industrial corrosives under oxidizing conditions, while possessing excellent resistance to stress corrosion cracking in fully age-hardened conditions.

Chemical Composition: UNS N07750 – Al: 0.40-1.0%, Cb: 0.70-1.20%, Cr: 14.0-17.0%, Fe: 5.0-9.0%, Ni: 70% min and Ti: 2.25-2.75% with full chemistry to AMS 5698

Inconel® 600

Inconel® 600 is a non-magnetic, solid solution strengthened alloy with excellent carburization and good oxidation resistance at elevated temperatures.

This alloy possesses resistance to sulfur compounds, has excellent mechanical properties, and has a combination of high strength and great workability.

Chemical Composition: UNS N06600 – Cr: 14.0-17.0%, Fe: 6.0-10.0% and Ni: 72.0% minimum per ASTM B166

Inconel® 625

Inconel® 625 is specifically used for its high strength and its outstanding resistance to pitting, crevice and corrosion cracking.

625 has excellent mechanical properties at both extremely low and high temperatures, and good resistance to acids as well as alkalis.

Chemical Composition: UNS N06625 – Cr: 20.0-23.0%, Mo: 8.0-1.0% Ni: 58.0% min and Cb: 3.15-4.15%

Monel® K500

Monel® K500 is a precipitation-hardenable, age-hardenable alloy which provides the superior corrosion resistance found in Monel® 400, with added strength and hardness for extra durability.

K500 has approximately three times the yield strength and double the tensile strength of Monel® 400. It also offers excellent mechanical properties from sub-zero temperatures up to about 480ºC.

Chemical Composition: UNS N05500 – Al: 2.3-3.15%, Ni: 63.0-70.0%, Ti: 0.35-0.85% and Cu: 27.0-33.0% with full chemistry to ASTM B865

Monel® 400

Monel® 400 is categorized for superior general corrosion resistance in a wide variety of media, as well as good weldability. The alloy is slightly magnetic at room temperature and is resistant to neutral, alkaline, and acid salts.

Chemical Composition: UNS N04400 – Ni: 63.0-70.0% and Cu: 28.0-34.0% with full chemistry to ASTM B164

Choosing Premium Nickel Alloys at CWI

With Central Wire Group of Companies, our customers get quality and durable materials that they can trust. Our raw metal alloy capabilities include nickel-copper, nickel-chromium, nickel-molybdenum-chromium, nickel-cobalt, red metals, and a wide variety of stainless-steel options.

Our capabilities allow us to support industries with challenges such as high temperatures, high levels of oxidation, a variety of corrosion risks and more. Our high strength and durable alloys are able to handle some of the physically demanding industries we serve, such as Mining and Oil and Gas.

To learn more about our full alloy catalog, visit our alloys page ici !

If you know the alloy your project requires, and are ready to invest in our quality manufacturing, Request a Quote with us today!