In today’s competitive markets and fierce economy, efficient production is a key across almost every industry. Oil and Gas in an industry which leans on operational efficiency for the success of its operations. With little available downtime to prioritize repairs and equipment replacement, the need for durable products that produce efficient performance is paramount in Oil and Gas refineries.

Continue reading to explore with us how the Oil and Gas industry demands consistent efficiency to meet its giant global demand.

Global Demand

One of the main factors in the need for efficient and consistent Oil and Gas production is the global demand for gasoline, diesel, jet fuel and other refined products. According to a Statista article, the global crude oil demand (which includes biofuels) has been steadily increasing over the last 20 years. In 2005, 83.65 million barrels per day were required whereas the projection to end 2024 is 104.46 million daily.

Crude oil production is relied on by so many companies across different industries. The world’s economy is largely dependent on fossil fuels, especially crude oil for applications such as:

- Transportation – Refined into fuels for vehicles, such as gasoline, diesel and jet fuel

- Heating – Crude oil can be used to heat buildings

- Electricity – Often used to generate electricity

- Asphalt – Crude oil is used to make asphalt, for road paving or roofing material

- Healthcare – Used in the making of lifesaving equipment such as pacemakers, MRI machines, IV bags and surgical instruments

- …and more!

With the multitude of industry applications that rely on crude oil production, the need for efficiency and effective Oil and Gas production has arguably never been greater. Highlighted below are our relevant product lines, which help Oil and Gas companies meet their strictest deadlines consistently.

Oil and Gas Production Efficiency Strategies

Due to the importance of consistent and efficient production, companies have devised strategies to ensure Oil and Gas operations are efficient. The energy demand is as high as ever, and with inefficient processes potentially raising prices, posing safety and environmental risks, and affecting the bottom line for corporations, these strategies help support both corporations et consumers.

Focus on Safety

Safe working conditions are crucial to the workplace in every industry, but worker safety becomes an entirely different priority in labor extensive industries like Oil and Gas. Having workers feel safe and prioritized not only boosts worker satisfaction but is critical to operational efficiency. Preventing risks of injury or harm requires continuous evaluation and adaptation but contributes to a healthy work environment and effective production.

Lean Management

Reducing the waste of time, materials and money in the Oil and Gas industry is crucial to meeting the high volume, time sensitive demands of the industry. Optimizing column and refining processes allows for the efficient production required from Oil and Gas plants. The reduction of waste in Oil and Gas can be done by using recycled materials, as well as using durable materials that are built to last even in harsh conditions.

Embracing Digitalization

In our modern technology-driven World, the digitalization of presque tous industry is clear. Even in Oil and Gas, an industry known for its labor extensive and hard-working environment, is being digitalized and enhanced with AI. This sector is turning to digitalization for solutions to environmental concerns, and to find ways to cut costs, boost production efficiency and to enhance data management and decision-making.

The Key Recovery Period: The Importance of Turnaround Season

A crucial component of Oil and Gas plant processes is scheduling their turnarounds and ensuring that the required repairs and maintenance is done to keep efficient production going.

This essential, scheduled period of downtime at refineries and production plants is used for maintenance, repairs, upgrades or complete overhauls of job sites. These turnarounds are key to ensuring safety, efficiency, and material longevity, as the condition of the materials used in crude oil production may be hard to analyze during busier parts of the year.

These downtime periods are strategically planned so that necessary repairs are done during periods of low demand for Oil and Gas products, such as the winter months, minimizing the financial impact. Although an expensive process up front, turnarounds in this industry are crucial to avoiding unplanned issues and repairs during busy times for production.

Are you planning your own turnarounds? Looking to source the equipment to make your necessary repairs and replacements? Look no further than Central Wire for the industry expertise and durable quality that you need!

Continue reading the section below to learn about our product lines that cater to this industry’s environmental challenges and efficiency demands, and to kickstart your efficient turnaround season with us!

How Central Wire Group of Companies Maximizes Oil and Gas Efficiencies

The labor intensive, competitive and time sensitive Oil and Gas industry also presents some environmental challenges, which demand durable performance from a few of our product lines. To meet the efficiency demands of the industry, our product contributions include:

GD™ - SUPA® Slicklines

Notre Slickline products can handle the harshest of Oil, Gas, & Geothermal conditions, both on-shore and off-shore. These high-strength cables are corrosion resistant, and perfect for any and well measuring line and downhole applications in both sour et sweet environments. Available in eight material options, each of our Slicklines also comes with certificates of conformance stating physical and mechanical properties, including alloy chemistry and breaking load.

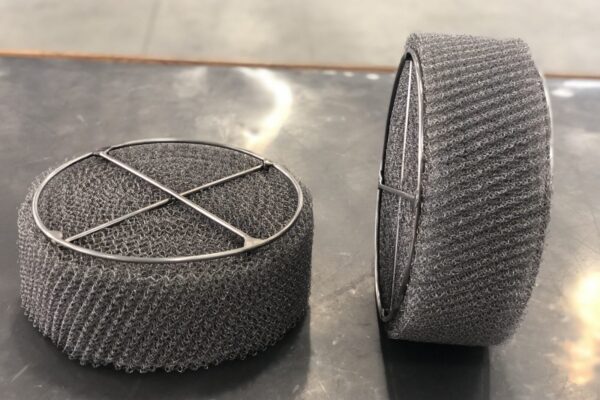

Tech-Mesh™ Products

Our Tech-Mesh™ product line is key to achieving the desired efficiency in your Oil and Gas applications. With the ability to custom fit our Bulk Mesh or Demister Pads to your exact specifications and needs, efficient liquid-gas separation could not be easier! We can adjust mesh density, shape, size, and offer a variety of alloy options to ensure your Oil and Gas efficiency only improves with CWI!

Profile/Shaped Wire

Our custom Shaped Wire offers the competitive advantage you need in your Oil and Gas applications. Wedge Shaped Wire, also known as triangular wire, is a common choice for filtration screens used in this industry. This product line creates heavy-duty screens, made by welding lengths of our Shaped Wire to support rods to add structure and rigidity.

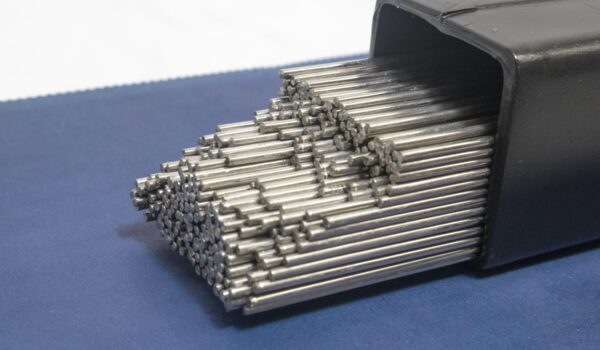

Generation4™ Welding Wire

Whether you’re looking to streamline your entire turnaround process with a multi-faceted manufacturer, or just need to perform some routine maintenance, our Welding Wire promotes the efficiency and durability you’re looking for. Adaptable to different levels of experience, and different Welding techniques, our Gen4™ alloy selection helps ensure your vessels and other equipment are built to last.