CWI Generation4™ Nickel Welding consumables meet or exceed the standard requirements of many high temperature or corrosion resistant alloy welding applications, and we certify it. Consumables ship from stock in a variety of packages, depending on your requirements or specif application. Select from our range of products below, all of which are manufactured to conform with applicable AWS, ASME, or UNS standards. Choose CWI Generation4 ™ Nickel Welding consumables for their proven performance, and let us show you the value that quality, experience, and customer support can provide.

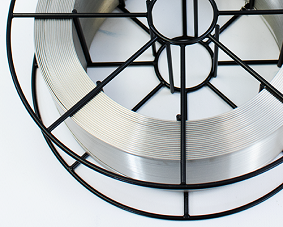

CWI Generation4™ Nickel Alloys are used in a variety of applications that require extreme thermal and/or corrosion resistance beyond what is achievable with stainless steel alloys. CWI Generation4 ™ Nickel Welding consumables are available in a wide range of Nickel Wire Alloys for use with all conventional welding processes. Below is a list of the standard nickel welding consumables we stock, and their typical chemical composition:

Typical Chemical Composition of Gen4 Nickel Welding Consumables

| Product | Specifications - AWS A5.14 | C | Mn | Si | Fe | Cr | Mo | Ni | Nb+Ta | W | S | P | Al | Ti | Cu |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GEN 55 | 0.05 | 0.25 | 0.15 | 43.60 | 55.90 | ||||||||||

| GEN 72 | ERNiCr-4 | 0.03 | 43.60 | Bal | 0.50 | ||||||||||

| GEN 99 | ERNiCl (AWS AS.15) | 0.05 | 0.22 | 0.05 | 99.60 | ||||||||||

| GEN 208 (FM 61) | ERNi-1 | 0.06 | 0.30 | 0.40 | 0.10 | 95.50 | 0.003 | 0.008 | 0.50 | 3.0 | <.15% | ||||

| GEN 276 | ERNiCrMo-4 | 0.01 | 0.55 | 0.04 | 5.50 | 15.55 | 16.10 | Bal | 3.65 | 0.002 | 0.009 | ||||

| GEN 413 (FM 67) | ERCuNi (AWSA5.7) | 0.75 | 0.10 | 0.55 | 1.0 | 0.006 | 0.35 | Bal | |||||||

| GEN 418 (FM 60) | ERNiCu-7 | 0.05 | 3.45 | 0.77 | 0.40 | 65.20 | 0.002 | 0.009 | 0.10 | 2.25 | Bal | ||||

| GEN 606 (FM 82) | ERNiCr-3 | 0.03 | 2.85 | 0.22 | 1.10 | 20.40 | 72.90 | 2.50 | 0.001 | 0.003 | |||||

| GEN 617 (FM 617) | ERNiCrCoMo-1 | 0.06 | 0.20 | 0.11 | 0.75 | 21.80 | 9.05 | Bal | 0.001 | 0.005 | 1.25 | 0.25 | 12.45Co | ||

| GEN 622/622LHIW (FM 622)* | ERNiCrMo-10 | 0.008 | 0.20 | 0.04 | 3.10 | 21.50 | 13.50 | Bal | 3.50 | 0.002 | 0.0058 | ||||

| GEN 625/625LHIW (FM 625)* | ERNiCrMo-3 | 0.009 | 0.05 | 0.12 | 0.62 | 21.90 | 8.65 | 64.50 | 3.70 | 0.002 | 0.006 | 0.17 | 0.19 | ||

| GEN 686 | ERNiCrMo-14 | 0.01 | 1.00 | 0.08 | 5.00 | 0.50 | 16.50 | Bal | 3.80 | 0.02 | 0.02 | 0.50 | 0.25 | 0.50 | |

| GEN 718 (FM 718) | ERNiFeCr-2 | 0.04 | 0.25 | 0.20 | 17.55 | 19.0 | 3.10 | 53.30 | 5.05 | 0.004 | 0.001 | 0.40 | 0.90 | ||

| GEN 825 (FM 65) | ERNiFeCr-1 | 0.01 | 0.45 | 0.25 | 29.0 | 21.50 | 3.10 | 42.60 | 0.001 | 0.015 | 0.10 | 1.0 | 2.0 |

Opciones de envasado

- Carretes

- Carretes

- Drums / Drum Packs

- Tubes

- View All Welding Wire Packaging Options