Central Wire Group of Companies' Wire Dusseldorf 2024 Showcase!

Thank you for stopping by our booth at Wire Dusseldorf 2024! We appreciate the opportunity to connect with you. In addition to meeting your company at the show, we're excited to provide you with further information about our products, capabilities, & manufacturing excellence.

Product Showcase:

At Central Wire, we pride ourselves on delivering innovative wire solutions that redefine industry standards. We specialize in manufacturing a wide variety of alloys, ensuring that our wires deliver exceptional performance in every application. Our top-quality manufacturing capabilities allows us to manufacture a range of wire & cable products

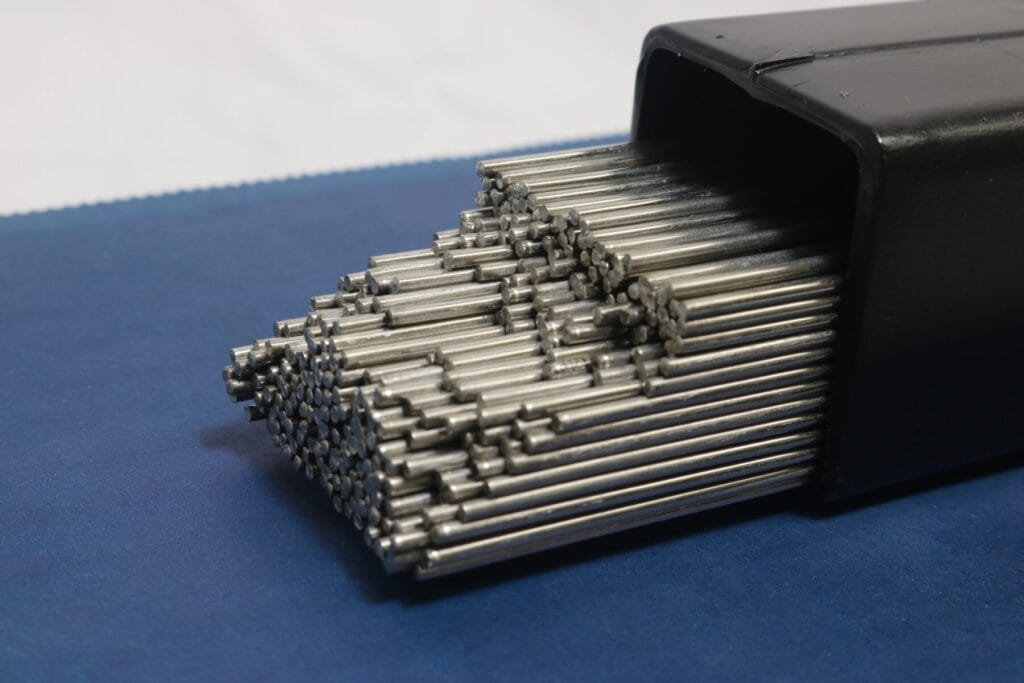

Welding Wire:

At Central Wire, we pride ourselves on crafting welding wire to match your exact specifications, whether you’re a fabricator or wholesaler, ensuring it meets diverse filler needs for various technical processes. Each product comes with a certificate of conformance, detailing its alloy chemistry and physical properties, providing you with confidence in its quality.

Manufactured in our ISO 9001:2015 certified facilities across the U.S., Canada, and the UK, our welding wire range encompasses a multitude of stainless and nickel-based alloys. You can count on us for professional-grade welding solutions that deliver reliability and performance.

Knitted Mesh:

At CWI, we specialize in stainless and copper mesh, offering our superior quality Tech-Mesh™ products crafted with precision and expertise. Our Tech-Mesh™ line includes Knitted Wire Mesh and Custom Demister Pads, meticulously manufactured at our Houston, Texas facility.

Knitted Wire Mesh is intricately woven from individual wires, allowing for exceptional flexibility and durability. Meanwhile, our Custom Demister Pads are tailored to your exact specifications, with options for wire diameters, alloys, mesh densities, and product geometries, all produced under precise equipment capabilities.

Profiled/Shape Wire:

Our profile wire is available in a range of sizes, from 1.25mm² to 150mm² (0.049”² to 5.90”²) CSA (Cross Sectional Area). Our profiles undergo manufacturing on specialized equipment meticulously ® designed and constructed in-house.

Each production line is equipped with in-line laser measuring systems, ensuring precise dimensional accuracy throughout the manufacturing process. Check out a full list of available alloys, including X750, MP35N®, & more here.

Other Products:

Federdraht: We manufacture a comprehensive range of cost-effective, corrosion-resistant stainless steel and nickel alloy spring wires. We offer spring wire in 300, 400, Nitronic®, and High Strength Stainless Alloys, while we specialize in High Performance Nickel Alloys, such as X750, Hastelloy®, Inconel®, & Monel®. Learn more about our spring wire alloys hier.

Slicklines: Produced in both the United States and the United Kingdom, our Slickline is meticulously manufactured from purpose-engineered alloys. Engineered to offer a seamless, weld-free, and brilliantly finished wireline, it’s available in various lengths extending up to an impressive 40,000 feet.

Stangenware: Our Premium Stainless Steel & Nickel Stangenware is crafted to customer specifications, reaching sizes of up to 0.750 inches. Central Wire boasts state-of-the-art equipment, ensuring rigorous quality control and positioning us as a frontrunner in specialty products. These bars are produced at our AS9100 Certified facility in Perris, California. For a comprehensive list of our specialty alloys, click hier.

Drahtseil: At our Pomfret, Connecticut facility in the USA, we specialize in drawing wire, stranding, and closing wire rope up to 1-1/4″ diameter. Our expertise extends to wire rope manufacturing in stainless steel, galvanized carbon steel, and a diverse range of other alloys, ensuring we meet your specific needs with precision and quality craftsmanship.

Beschichtetes Kabel: Our coated cable solutions involves a meticulous process of extruding a plastic jacket onto standard aircraft cable or wire rope, to enhance the cable’s durability and functionality, alongside improving aesthetics. Our coated cable not only adds a layer of protection against abrasions but also ensures resilience in harsh environmental conditions. With the capability to coat cables ranging from 1/32″ to 1 3/8″ in size, we offer a diverse selection of jacketing materials, including our specialized LOLON® series.

Industries Served:

At Central Wire, our manufacturing capabilities cater to a multitude of industries, including:

• Oil and gas exploration

• Aerospace advancements

• Construction projects

• Medical innovations

• Marine applications

• Architectural marvels

This list provides just a glimpse into the diverse range of sectors we serve. Our commitment to quality and innovation drives us to continually adapt and expand our offerings to meet the evolving demands of today’s dynamic marketplace.