The Sustainability Trends Driving the Automotive Industry

Continue reading to learn a few ways that these changes are being implemented in vehicles and plants around the world.

4 Ways We Ensure Cold Heading Material Consistency

Designed to withstand mission critical environments and harsh conditions, material consistency and strength is crucial to the performance of all Cold Heading products.

CWI’s Precision Machining Capabilities Serving Markets with the Highest Quality Requirements

Our CNC Machining tools include milling machines, turning machines and more, which help us meet your exact specifications!

The Importance of Precipitation Hardening

Precipitation hardening is a heat treatment process which increases the tensile strength and hardness of various alloy families. In some cases, this process can increase the yield strength of an alloy fivefold.

Unsere zahlreichen CNC-Maschinen und ihre Fähigkeiten

Specific machinery is required to create the right product to serve our customer base with short lead times.

Fahrzeugrestaurierung und Schweißtechniken

Beyond sourcing parts and deciding on paint, interior design and other aesthetic features, one of the main tasks is welding repairs. There are plenty of body shops capable of doing this, but many car restoration jobs are preferably done by the individual.

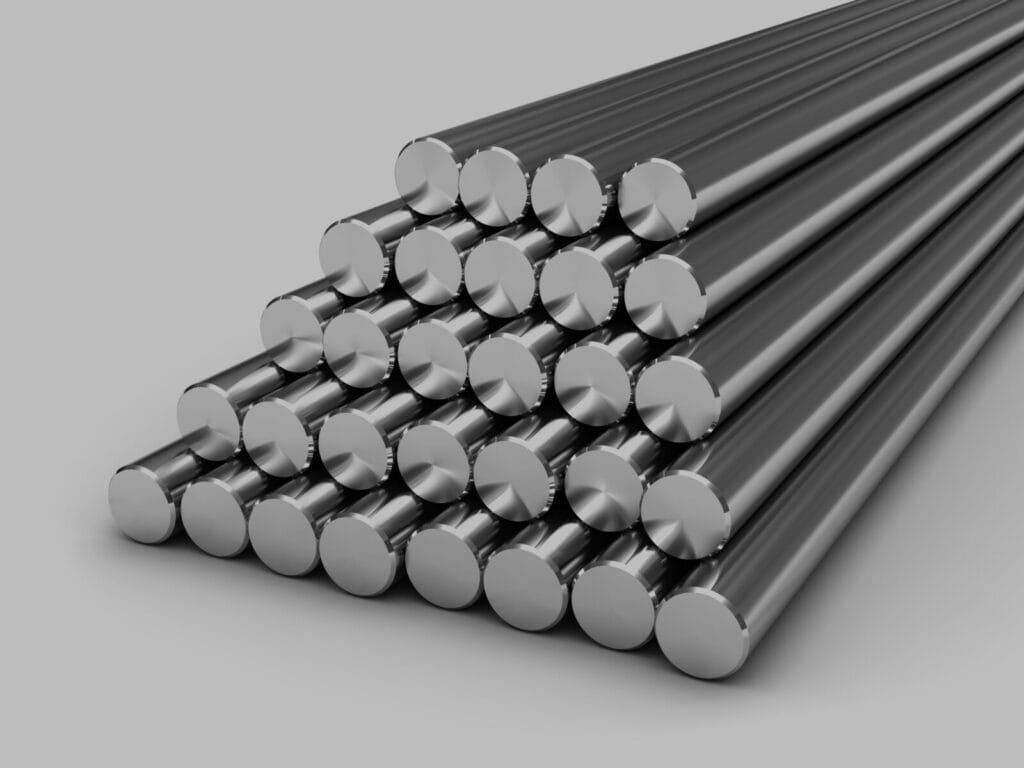

Central Wire fertigt Stangenmaterial für die Luft- und Raumfahrt und darüber hinaus

Turning premium bar stock metals into fasteners, engine components, fasteners and more is made easy with our quality manufacturing.

Investieren Sie in die richtigen Kabelkonfektionen?

Are You Investing in the Right Cable Assemblies & do you know which one is right for your application? Let’s dive in and find out!

Industriezweige, die von Stangenmaterial angetrieben werden: Ein tiefes Eintauchen in Premium-Legierungen

From aerospace to automotive, oil and gas to industrial applications, and renewable energy, Bar Stock’s adaptability and robustness play a pivotal role in shaping our world.