Finding a manufacturer with the premium metal alloys your applications require, with the ability to tailor products to your exact needs can be a challenge. In the world of manufacturing, the choice of materials can significantly impact the quality and performance of the end-use product.

Thankfully, at CWI we understand the need for customization and precise manufacturing. No two applications, projects, or customers are the same. Our talented team helps ensure you make the right material choice for the various demands of your industry.

Premium Bar Stock at Central Wire

Stangenware is a versatile form of raw material that is critical in applications across a wide spectrum of industries. It stands out for its exceptional adaptability, aligning precisely with diverse project needs in industries such as Aerospace, Automotive, Oil and Gas, and Renewable Energy. Customization is the cornerstone, enabling alloy selection based on factors like corrosion resistance, durability and strength.

This is especially critical in Aerospace, where extreme conditions demand robust materials. Additionally, Bar Stock’s dimensions and mechanical properties can be tailored to your exact standards, ensuring seamless component integration. Alloys further enhance performance, reducing friction, bolstering corrosion resistance, and ensuring consistency.

Let’s now delve into key alloys used in our Bar Stock product line, discovering their importance in various industries.

Our Premium Bar Stock Alloys

A286 Alloy - AMS5731/AMS5726/AMS5853/AMS5732

- Alloy Composition: A286 is a nickel-iron-based superalloy with additional elements such as chromium, titanium, and molybdenum. Its composition makes it highly resistant to corrosion and oxidation.

- Strength and Durability: A286 boasts high tensile strength and exceptional durability, making it suitable for applications demanding both strength and corrosion resistance.

- AMS Specifications: A286 meets various AMS specifications, including AMS5731, AMS5726, AMS5853, and AMS5732. These specifications define the alloy’s precise properties and performance standards.

- Customization: A286 Bar Stock can be customized to meet specific industry requirements. It offers excellent mechanical properties, making it ideal for applications in Aerospace, Automotive, and Industrial manufacturing.

Inconel® 718 - AMS 5962/AMS 5662

- Alloy Composition: Inconel® 718 is a nickel-chromium-based superalloy known for its exceptional high-temperature strength and corrosion resistance. It contains elements like nickel, chromium, molybdenum, and niobium.

- AMS Specifications: Inconel® 718 conforms to AMS specifications, including AMS 5962 and AMS 5662. These specifications set rigorous standards for the alloy’s performance and reliability.

- High-Temperature Performance: Inconel® 718 excels in high-temperature applications, maintaining its strength even at elevated temperatures. It is widely used in Aerospace, Renewable Energy, and Nuclear applications.

- Corrosion Resistance: This alloy exhibits excellent resistance to corrosion and oxidation, making it suitable for challenging environments.

Inconel® 625 - AMS 5666

- Alloy Composition: Inconel® 625 is a nickel-chromium-based superalloy that includes elements like nickel, chromium, molybdenum, and niobium. It’s renowned for its corrosion resistance and high-temperature performance.

- AMS Specification: Inconel® 625 adheres to AMS 5666, a specification that ensures its quality and reliability for various applications.

- Corrosion Resistance: Inconel® 625 offers outstanding resistance to chloride pitting, fatigue stress, and oxidation. It’s commonly used in MarFbaine, Chemical, and Aerospace industries.

- High Creep Rupture Strength: This alloy has a high creep rupture strength, making it ideal for applications where materials are exposed to high stress over extended periods.

Inconel® 600 - AMS 5665

- Alloy Composition: Inconel® 600 is a nickel-chromium-based alloy containing elements like nickel, chromium, and iron. It is known for its resistance to oxidation and corrosion at elevated temperatures.

- AMS Specification: Inconel® 600 adheres to AMS 5665, which defines its properties and performance standards.

- High-Temperature Performance: Inconel® 600 is valued for its ability to maintain strength and resist oxidation at high temperatures. It’s used in applications like heat treating and nuclear engineering.

- Ease of Welding: Compared to other Inconel® variations, Inconel® 600 is relatively easy to weld, enhancing its versatility in fabrication.

Bar Stock Manufacturing – How it Works

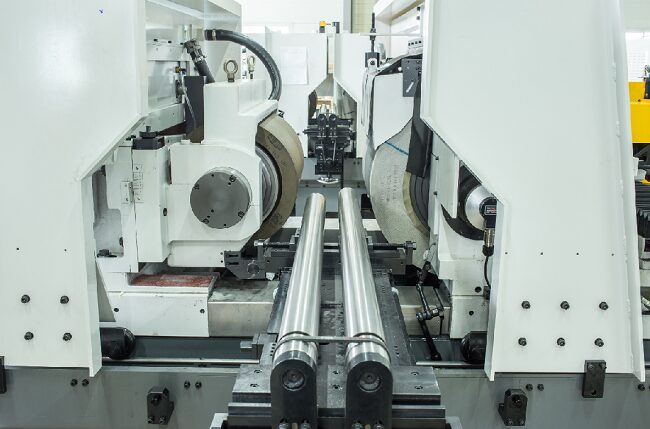

A crucial part of what makes Central Wire a global leader in Specialty Bar Stock products is our custom manufacturing and machining capabilities. Notably, our through-feed centerless grinding machines maximize our ability to meet extremely precise tolerances.

The process consists of a workpiece being constantly fed through the machine between a grinding wheel and a regulating wheel. This process not only allows for us to meet exact customer demands but offers improved surface finish as well.

This manufacturing process helps our Bar Stock find use in applications including;

- Bearings and Bushings

- Engine Components

- Verbindungselemente

- Bolts, Screws Nuts

- Landing Gear Components

Choosing Central Wire

In conclusion Bar Stock, with its remarkable adaptability, is a vital raw material in numerous industries. Customization to specific project needs, coupled with the use of alloys like A286, Inconel® 718, Inconel® 625, and Inconel® 600, allows for unparalleled performance in demanding applications.

At CWI, we specialize in providing top-quality Bar Stock and a wide range of alloys, precisely tailored to meet your project’s requirements. Our expertise and commitment to excellence make us the ideal partner to help you achieve your goals.

Ready to invest in premium Bar Stock metals with CWI? Angebot anfordern heute mit uns!