In engineered products, performance is not judged by how something looks on day one. It is judged by how it behaves year after year, in the environments and conditions it was built to withstand. To guarantee that level of performance, customers need evidence — not assumptions.

In CNC Machining and Seismic Cable Systems, traceability becomes the technical backbone that transforms precision into confidence. Every dimension, every material choice, every machining pass, and every load test must be recorded so engineers and installers can verify compliance before deployment.

This is how Loos & Company and Central Wire deliver traceability that is measurable, searchable, and fully aligned with industry expectations.

Central Wire’s CNC Machined Components und Industrial Tools demonstrate how longevity is woven into design and manufacturing from the beginning. These products serve industries where downtime is costly, accuracy is essential, and equipment must continue to perform long after installation or first use.

CNC Machining: Traceability in Every Dimension

A machined part may appear simple, but it carries a complex history — material selection, heat treatment, tool paths, inspections, measurement verifications, and final approvals. For the industries that rely on these components, such as Aerospace, Military, Marine, and Industrial machinery, documentation is essential for both compliance and performance assurance.

Every CNC component manufactured at Loos & Company includes:

- Lot identification tied to melt chemistry and material certs

- Dimensional inspection reports for all critical features

- Process logs that track machining parameters

- Surface finish measurements confirming tolerance stability

- Verification of heat treatment or secondary operations

- Zertifizierungen tied directly to the part’s production record

This level of traceability ensures that every part can be traced backward — not only to the day it was machined, but to the alloy it was produced from, the tools used to cut it, and the measurements taken to confirm its final geometry.

When Structural Safety Depends on Documentation

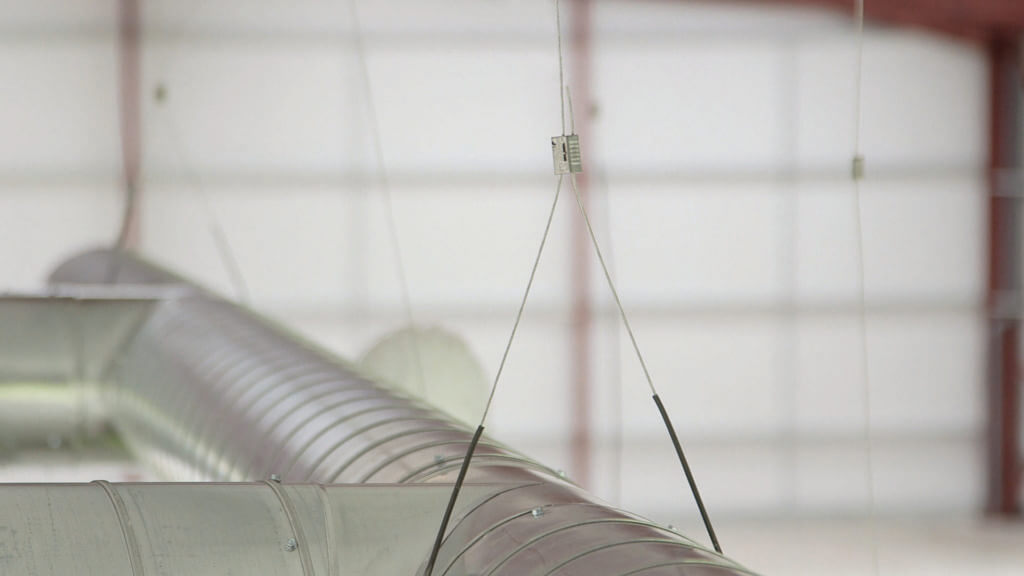

Seismic Cable Systems are engineered for a single purpose: to protect structures and the people inside them. These assemblies must act with precision during seismic events, supplying stability, damping movement, and distributing forces safely. Their reliability depends on documented proof that every component meets performance requirements — before installation ever begins.

Traceability is built into the Seismic Cable manufacturing process:

- Raw material identification confirms alloy and tensile capability

- Load testing results are tied to each specific Assembly

- Dimensional verification ensures fittings and cables match engineered requirements

- Inspection data is logged and attached to project records

- Zertifizierungen accompany every shipment

For contractors, engineers, and inspectors, this documentation is not optional. It is the evidence they rely on to confirm compliance with building codes, project specifications, and safety standards.

A Seismic Cable System is only as strong as its traceability system — because that documentation is what ensures the product performs during the moment it matters most.

Proven Quality Across Every Stage

n industries where failure has serious consequences — structural collapse, equipment malfunction, load instability, or safety hazards — traceability is not simply a value-added service. It is a requirement.

CNC Machining depends on validated dimensions because many parts must interface with other precision components. Seismic Cable Systems depend on verified load performance because their job is to reinforce structures during unpredictable, high-energy events.

Traceability provides assurance that the material, the machining, the assembly, and the testing all fulfill their roles without exception.

- It builds reliability into the process.

- It builds longevity into the installation.

- It builds confidence into the final outcome.

Consistency Across Global Facilities

Loos & Company and Central Wire operate across three regions — the United States, Canada, and the United Kingdom. All facilities share one unified approach to traceability, documentation, testing, and certification.

This means a CNC component machined in Pomfret carries the same documentation structure as one produced in the U.K.

A Seismic Cable shipped to a major contractor in California includes the same traceability sequence as one delivered to a project in Europe.

This consistency reinforces supply chain reliability, simplifies audits, and ensures quality is not dependent on geography — only on the system behind it.

Traceability Builds Trust

Whether it’s a machined housing for an Aerospace assembly or a Seismic Cable placed into a building’s support structure, customers need more than dimensions and tensile values — they need proof.

Traceability delivers that proof. It provides transparent, verifiable insight into how each product was made and tested. It ensures compliance, strengthens confidence, and removes uncertainty from high-risk applications.

Next Steps

Explore our CNC Products und Seismic Bracing Products to see how Central Wire delivers accountability through testing, certifications, and products built to last.

For project guidance or to request a quote, contact our team today at sales@loosco.com