Learn about our high-performance, age hardenable, Iron-Nickel-Chromium Alloy, A286.

A286 Overview

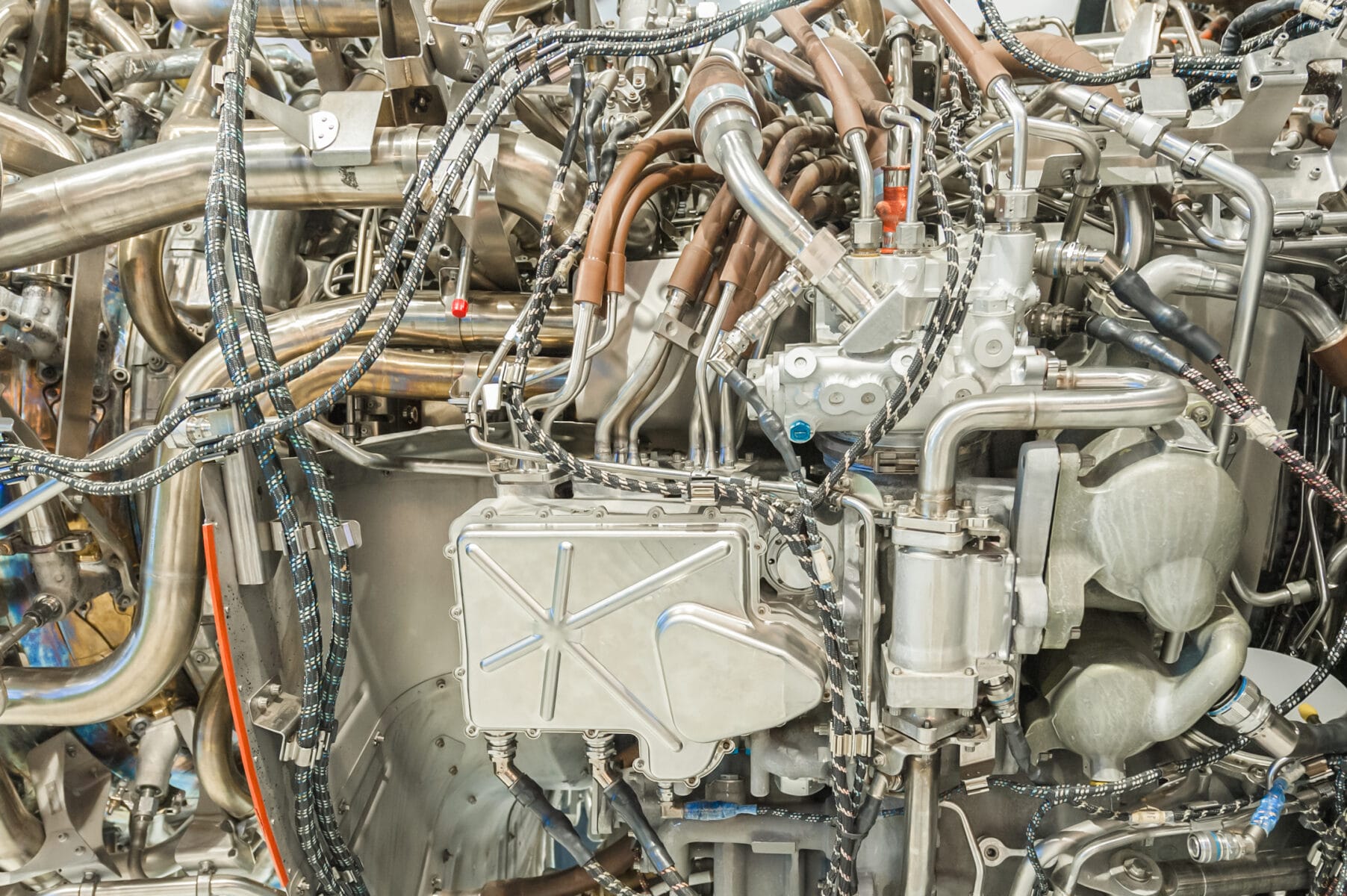

Alloy A286 is an age-hardenable iron-nickel-chromium alloy developed for use in environments that demand both high strength and reliable corrosion resistance at temperatures reaching up to 700°C (1290°F). Its robust mechanical properties make it well-suited for components in aircraft and industrial gas turbines. Additionally, it is commonly employed in the offshore oil and gas sector, as well as in fasteners and automotive engine parts exposed to elevated heat and stress conditions.

Ageing process – heat treatment to be held 705 – 760 °C (1300 – 1400 °F) for 16 hours and then air cooled.

A286 Composition

| C | Mn | Si | P | S | Kr | Ni | Mo | Ti | B | V | Co | Al | Cu | Pb | Fe | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min % | 0.03 | 1 | – | – | – | 13.5 | 24 | 1 | 1.9 | 0.003 | 0.1 | – | – | – | – | Bal |

| Max % | 0.08 | 2 | 0.5 | 0.02 | 0.015 | 16 | 27 | 1.5 | 2.3 | 0.01 | 0.5 | 1 | 0.35 | 0.5 | 0.005 |

Designations and Specifications

Designations

- W.Nr 1.4944

- W.Nr 1.4980

- UNS S66286

Specifications

- AMS 5731

- AMS 5734

- AMS 5737

- AMS 5853

- ASTM A453

- BS HR 52

- BS HR 650

- ISO 15156-3

- NACE MR 0175

Anwendungen

Common A286 applications include:

- Super Chargers

- After Burner Parts

- Verbindungselemente

- Jet Engines

Zerreißfestigkeit

| Condition | Annealed | After Ageing | ||

|---|---|---|---|---|

| N/mm² | KSI | N/mm² | KSI | |

| Annealed & Aged | <750 | <109 | 950 – 1300 | 138 – 188 |

| Condition | As Drawn | After Ageing | ||

|---|---|---|---|---|

| N/mm² | KSI | N/mm² | KSI | |

| Spring Temper & Aged | 1050 – 1250 | 152 – 181 | 1200 – 1500 | 174 – 218 |

Verpackungsoptionen

- Spulen

- Spulen

- Bars/Cut Lengths

- Kundenspezifische Verpackung verfügbar