At Central Wire, the strength of our manufacturing is seen in our precision, with the ability to meet tight tolerances and precise project specifications with ease. It is also proven in our vast product capabilities, which allows us to serve more than 20 unique industries.

We are also proud to offer Domestic manufacturing options to consumers in each of the 3 countries we operate in; Canada, the USA and the UK. In times of Global trade shifts and national pride, trust that Central Wire can provide products that are drawn, assembled, and customized to your specifications Domestically.

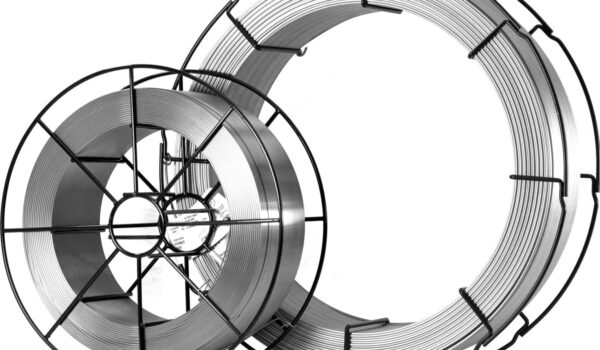

Continue reading to explore the capabilities of our Canadian manufacturing, specifically the industry applications of our Gen4™ Welding Wire.

Central Wire’s Domestic Manufacturing

60 years of Domestic manufacturing experience in Canada has allowed us to grow a presence in many Canadian markets, with three of our primary product lines leading the way. Our Fine Wire, Tech-Mesh™ and Welding Wire are trusted for durable performance by many Canadian businesses and end-users.

As Canada’s only Wire drawing and annealing company, and the sole manufacturer of Stainless and Nickel Welding Wire in the country, we set the standard for high-quality Canadian manufacturing. Check out a detailed list of our Welding Wire’s common applications below.

Generation4™ Welding Wire – Common Industries

Our wide variety of Stainless, Nickel, Nickel-Chrome, Cobalt and Copper alloy Welding Wire is suitable para MIG, TIG and SAW Welding procedures, offering versatility across many different industries. Below are some of the most common industries our Domestically manufactured Welding Wire is used in, and some application examples.

Petróleo y gas

The corrosive environment and production demands in the Petróleo y gas industry require premium performance from all raw materials. Working alongside our highly customizable Tech-Mesh™ product line in Oil and Gas refineries, here are some of the ways our Welding Wire supports efficient and safe crude oil production.

- Head Plates (Top and Bottom Heads)

- Secure, leak-tight welds at the vessel heads are critical for maintaining structural integrity and pressure containment.

- Vessel Shell Welds

- Continuous welds that form the pressure-retaining envelope, ensuring that the vessel can handle high internal pressures and harsh service conditions.

- Support Frame Attachment

- Support frames, which are welded to Demister Pads, provide enough structural strength to keep mesh in its desired form, size, and orientation during operation.

Aeroespacial

Aeroespacial is an industry with stringent standards for mission-critical safety and compliance. Many of our custom engineered solutions meet military-grade standards, offering unmatched quality, reliability and precision. Explore how our Welding Wire can support this industry’s need for durability and consistency.

- Landing Gear Components

- Reliable welds that last help ensure landing gear can absorb stress and impact during takeoffs and landings.

- Engine Nacelle and Exhaust Ducts

- These welds secure the engine housing and ensure that exhaust components maintain leak-tight integrity under severe thermal cycles.

- Fuselage Skin & Frame Reinforcements

- Ensure aerodynamic integrity and structural strength by securely attaching skin panels to the internal framework.

- Wing Spar & Wing-to-Fuselage Joint

- Bearing high aerodynamic loads and stress during flight, quality welds here are vital to structural integrity and safety.

Automotor

For either repair experts or Automotor manufacturers, Welding processes play a key role in the structural appearance and on-road performance of vehicles. Learn how our Welding Wire catering to MIG, TIG and SAW Welding types help assemble and repair key vehicle components.

- Exhaust Tip Junction

- Often, the exhaust tip is made of stainless steel while the pipe may be carbon steel. TIG welding with a 309L filler compensates for dilution, ensuring a durable, corrosion-resistant joint between dissimilar metals.

- Body Panels

- MIG Welding is ideal for rapidly and uniformly constructing body panels, typically on a large, flat surface for high volume vehicle production.

- Front Grille

- The aesthetic capabilities of TIG Welding are showcased in the front grille, with welds that maintain appearance and exhibit excellent corrosion resistance.

- Engine Mount

- Engine mounts require strong, durable joints to manage vibration and load, making controlled Welding essential.

Buying Canadian Made with Central Wire Industries

There is no better time than the present to Buy Domestically manufactured Canadian products from Central Wire! Our focus and experience with bringing high-quality, precision products to the Canadian market makes us a trusted source for these and many other industries.

Visit our Canadian manufacturing webpage aquí to view our full scope of Domestic manufacturing capabilities and expertise in one place.

To invest in Domestically manufactured Welding Wire to help kickstart your next project, Request a Quote with us today!