One of the new stars of our Tech-Mesh™ product line is premium packing solutions, which we now offer in both structured and random formats.

Both structured and random packing provide unique advantages in the oil and gas industry, as well as other industries. Refinery towers and dehydration columns require the precise performance that packing solutions provide. Enhancing your oil and gas operations is made easy with structured and random packing products.

When it comes to mass transfer efficiency, we not only have the product solutions, but we also have the manufacturing capabilities that separate us from the competition!

Whether your project entails midstream, chemical, refinery or distillation columns, we have the solutions you need. Each structure can achieve efficient mass transfer using structured and random packing.

Continue reading for more information on packing and its functions, and to find out how to purchase through us today!

Structured Packing

Taking a closer look at advancements in mass transfer optimization, let’s begin with a consistent performer whose structure ensures reliability.

Structured packing solutions are designed to product consistent performance, while offering optimal pressure drop and efficiency. Typically, they are constructed from corrugated and textured metal sheets. This composition ensures an excellent, uniform wetting under both low and high liquid loads.

No mass transfer function is too complex or difficult for structured packing. The many strengths of this include:

- A high surface area for improved mass transfer efficiency

- Reduced pressure drops across the column

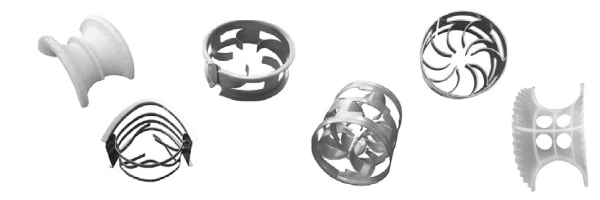

Random Packing

When exploring innovations in column efficiency, sometimes there is no need for a uniform structure to obtain the liquid-gas filtration that’s required.

Random packing is a technique of packing a column with specifically sized and designed materials in random orientations. These materials can vary from metal to plastic to ceramic. The individual pieces increase the surface area within a column or tower, thus increasing liquid-vapor contact and desired mass transfer.

In the most robust applications, random packing offers reliable and durable performance. It is a suitable choice for a wide range of applications, with flexibility and reliable performance ensured under various operational conditions.

Standing out in mass transfer applications, random packing offers several key features:

- Cost-effective solutions in mass transfer applications

- Strong resistance to fouling

- Easy handling and installation

Fundamental Properties and Functions

When choosing between random and structured tower packing, there are a few key factors. Here are the four main capabilities considered in the mass transfer process.

Surface Area

Packing styles with a higher surface area can facilitate more liquid-vapor contact, which is a vital consideration for effective mass transfer.

Pressure Drop

Minimizing pressure drop is crucial to reduce energy consumption and enhance the general column performance.

Capacity

The ability of the packing style selected to handle the volume of liquid flow without flooding or malfunctioning, to ensure continuous operation.

Mass Transfer Efficiency

Efficiency in this case measures the degree to which the structured or random packing can facilitate the liquid-vapor contact at a given energy input.

Types of Structured Packing

There are multiple types of structured packing which excel in different conditions. Dependent on pressure levels and the specific application, any or multiple of these styles of packing may be the right choice. Let’s look at four types and their separation functions.

Sheet Metal

Sheet metal packing consists of corrugated and textured, often perforated sheets of stainless steel oriented at an angle, which enhances contact between vapor and liquid phases. This style of packing improves mass transfer efficiency and reduces pressure drop across the column. Sheet metal packing is suitable for both low and moderate pressure applications.

Wire Gauze

Wire Gauze packing is comprised of specific metal wires, including stainless steel, níquel and copper, and is woven into a wire gauze. It is specifically formatted for column processes which require fine control, with lower liquid loads. Wire gauze is ideally used in applications where a high level of mass transfer efficiency and minimal resistance are crucial.

Wire Mesh

Wire Mesh packing is made up of ultra fine that is knitted and crimped to a specific finished density. It possesses enhanced self-surface wetting characteristics from these fine diameter wires. Wire mesh provides high mass transfer efficiency, maximizing surface area and promoting efficient vapor-liquid contact. Compared to gauze, mesh transfers mass at a higher pressure drop, and is suitable for most refining and gas absorption processes.

Grid Packing

Grid packing is a robust packing style, featuring either corrugated or bladed grid configurations. It is fabricated for ease of cleaning and installation. Its structure allows the ability to handle solids and dirty streams better than other types of packing, and grid packing can withstand processes prone to fouling or coking. Grid packing is a great choice for packing solutions with high operational demands, and risks of clogging columns.

Malla de alambre de punto

Shifting the focus from packing beds to separation, another mesh product we provide is knitted wire mesh. Used in chemical, oil and gas and other industries, this durable mesh boasts flexibility and reliability within all applications.

Our knitted wire is efficient and economical and is knitted on state-of-the-art equipment. Our mesh maximizes separation efficiency, minimizes pressure drop, and promises performance.

Demister Pads

The final knitted wire mesh component in a column is mist eliminators, or demister pads. Almost every packed bed will also have a demister pad. These pads trap mist droplets carried through by rising gas. Their liquid-gas separation capabilities are the key to ensuring potentially hazardous mist is trapped while clean vapor rises.

Vapor carries mist as it rises, so even at the end of the process, there are droplets remaining. These individual mist droplets are trapped by these pads and drop into the pool of liquid below. Our demister pads are manufactured from premium stainless steel, copper or custom alloys to fit the needs of your filtration product!

These mesh products help create efficient mass transfer using structured and random packing.

Random and Structured Packing Offered by CWI

Adding to the extensive list of knitted wire mesh products Central Wire Group of Companies can offer is both structured and random packing.

Choosing the right packing solution for your oil and gas operation is crucial to the integrity of the vessel and process. Product purity and consistency, safety, environmental compliance and more are jeopardized if mass transfer is not done thoroughly.

Want to learn more about effective mass transfer using structured and random packing? Check out our new packing page on the site aquí!

Ready to invest in packing, demister pads, or our other knitted wire mesh products? Request a quote with us today using the button below!