Welding Wire | Fine Wire | Knitted Mesh | Custom Demister Pads and More!

Canada’s only wire drawing and annealing company, providing high-performance wire tailored to the needs of distributors & end-users.

Central Wire Industries, founded in 1955 and headquartered in Perth, manufactures and distributes Stainless Steel, Nickel alloy, and Copper and Brass wire products worldwide. With 2 dedicated manufacturing facilities in Canada, Central Wire is focused on bringing high-quality, precision products to the Canadian market, in a range of industries, including: Aerospace, Automotive, Construction, Oil & Gas, & beyond!

Learn about our Canadian facilities, Domestically manufactured products, available alloys, product applications, and how we support Canadian businesses in more depth below.

Our Canadian Facilities - Quality Domestic Manufacturing

Perth, ON

Central Wire’s flagship facility in Perth, Ontario was opened in 1955 and has remained a staple in the Perth community ever since. With over 50 employees, the Perth facility specializes in Welding Wire & Fine Wire in Stainless, Nickel, Copper, and Specialty alloys.

Calgary, AB

Central Wire’s second Canadian location in Calgary, Alberta was opened in 2018, originally for distribution and then quickly expanded to having dedicated manufacturing services. The Calgary plant primarily manufactures Knitted Wire Mesh & Custom Demister Pads.

Ready to learn more? Browse Our Product Lineup!

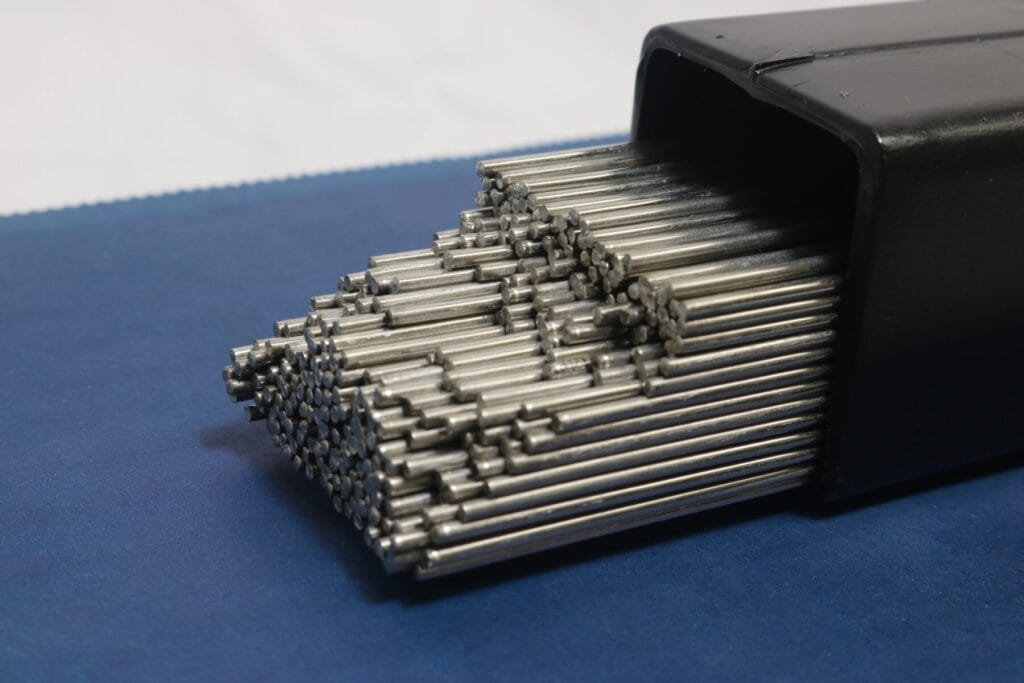

Filo per saldatura

CWI Generation4™: Saldature MIG, TIG e SAW

Our evolutionary CWI Generation4™ – specialty alloy welding products are manufactured with the highest quality raw materials, including; Stainless, Nickel, Specialty Nickel-Chrome, Cobalt and Copper. Whether you’re a fabricator or a wholesaler, our Welding Wire is available to suit your project needs. MIG, TIG, and SAW weld types are all available, Domestically manufactured in our ISO 9001:2015 certified facility. Central Wire is CWB approved, and on the AML list, a testament to the quality of our Domestic manufacturing.

Central Wire is proud to be Canada’s ONLY manufacturer of Stainless and Nickel Welding Wire.

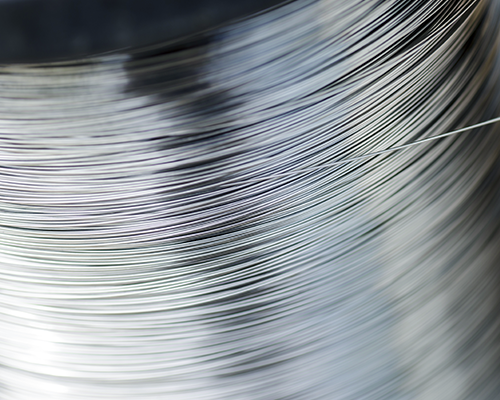

Filo sottile

Manufacturing Fine Wire for Aerospace, Medical & More

Tailored to meet your specifications for Medical, Aerospace or Commercial quality products we are able to meet tight tolerances from: 0.001” up to .032”, with custom Fine Wire sizes available by request. Available in tempers ranging from soft annealed to spring temper and a wide range of packing from specialty bobbins to bulk packages. Our Domestically manufactured Fine Wire supports Canadian businesses, with common applications including woven wire mesh and hose manufacturing.

Tech-Mesh

Knitted Wire Mesh/Custom Demister Pads

Tech-Mesh™, Knitted Wire Mesh is manufactured for maximum separation efficiency & minimized pressure drop. Our knitted products combine flexibility and durability, making wire mesh ideal for filtration, alongside other industry uses. Our Tech-Mesh™ manufacturing process is precise from rod processing and breakdown to support frame attachment, allowing us full quality control. Finished products can be customized to your desired mesh density, geometry, crimp style, and more.

Leghe speciali di acciaio e nichel

Premium Wire Manufacturing, including x750, Mp35N® & Beyond

Leghe inossidabili:

302S, 302HQ, 304, 304L, 304VM, 305, 309, 310, 316, 316L, 316LVM, 316Ti, 317, 317L, 321, 347, 409, 409CB, 410, 420, 416, 420, 430, 431, 434, 439, 446, 17-7 PH (631), 13-8Mo, 15-7Mo, A286, 904L, Duplex 2205, Nitronic® 32, Nitronic® 50, Nitronic® 60

Leghe di nichel:

Monel® 400, Monel® K500, Inconel® 600, Inconel® 601, Inconel® 625, Inconel® 718, Incoloy® 800, Incoloy® 825, Nickel 200, Nickel 201, Nickel 205, Nickel 211, Alloy 20 (20Cb3), C276, 330, 35-19Cb, Invar36

Leghe speciali:

X750, Hastelloy® X, L605, MP35N®

Saldatura:

ER209, ER218, 309LMo, ER409NB

Nickel Chrome:

276, 622, 625, 686, Alloy 59

Leghe di rame:

- Serie rame:

C10100, C10200, C11000, C70200, C70500, C70700, C71100, C72150, C71500, C72500, C74500, C75200, C75700 - Serie Bronzo:

C22000, C22600, C41100, C50700, C50900, C51000, C52100, C65100, C65500, C65600 - Serie in ottone:

C23000, C24000, C26000, C-260b, C27000, C27400, C42500

…and many more! These specialty alloys provide superior corrosion resistance, high strength, and excellent performance in extreme environments. CWI’s alloys are ideal for applications requiring durability and reliability, such as Aerospace, Chemical Processing, and Oil and Gas industries. Browse an extensive list of our Stainless e Nichel leghe di seguito.

Qualità e test

ISO9001 Certification, Non Destructive Testing & More

Our multi-site ISO 9001:2015 registration by BSI covers the manufacture and distribution of round, stranded and shaped Stainless, Nickel, Copper, Zinc, and other alloy bar and wire products in various sizes and tempers, including ferrous and nonferrous Welding Wire. Scarica qui la nostra certificazione ISO.

PRODUCT APPLICATIONS

Automotive

Aerospaziale

Petrolio e gas