Repair and fabrication professionals alike understand the importance of a weld that lasts. Our knowledge and expertise in the Welding Wire manufacturing sector allows us to support the strict material requirements of both groups. At Central Wire, our specialized Generation4™ Welding Wire is designed for superior strength and adaptability.

The versatility and alloy selection in this product line is top-of-the-line, with a multitude of stainless and nickel-based alloys to ensure the perfect fit for your project. You can find a comprehensive list of our Welding Wire alloy options here.

Voltage, amperage and gas must all be considered before making a decision on both your Welding Wire material, and your welding procedure. Use our Recommended Welding Procedures Page as a premier resource for detailed information on these three factors.

Continue reading below to learn about the Arc Welding types that Central Wire can manufacture for.

The Welding Types That We Support

Our products and expertise make us leaders across various welding applications, industries and procedures. The most common welding procedures that we support are Gas Metal Arc Welding (GMAW), Gas Tungsten Arc Welding (GTAW) and Submerged Arc Welding (SAW).

Each of these processes offers unique benefits and drawbacks, depending on the exact conditions of your project. Let’s take a deeper dive into the keys to each of the Arc Welding procedures that we cater to:

Gas Metal Arc Welding (GMAW)

Considered the most common industrial welding process, GMAW or MIG (Metal Inert Gas) Welding is widely considered to be uncomplicated, and the easiest Welding process to learn. In MIG Welding, the welding gun brings all the required components (power, filler metal, shielding gas) together at the weld point.

This procedure is economic, quick, efficient, and typically works best with thin to medium thickness materials. Carbon steel, stainless steel, copper, and aluminum are among the metals that MIG Welding caters to the best.

Typical application of this Welding procedure includes many industrial and general manufacturing applications, in which the final weld conditions are not very demanding or intense. Automotive repairs or manufacturing with lighter, thinner materials can also be a successful application of MIG Welding, especially if speed and efficiency are a priority.

Gas Tungsten Arc Welding (GTAW)

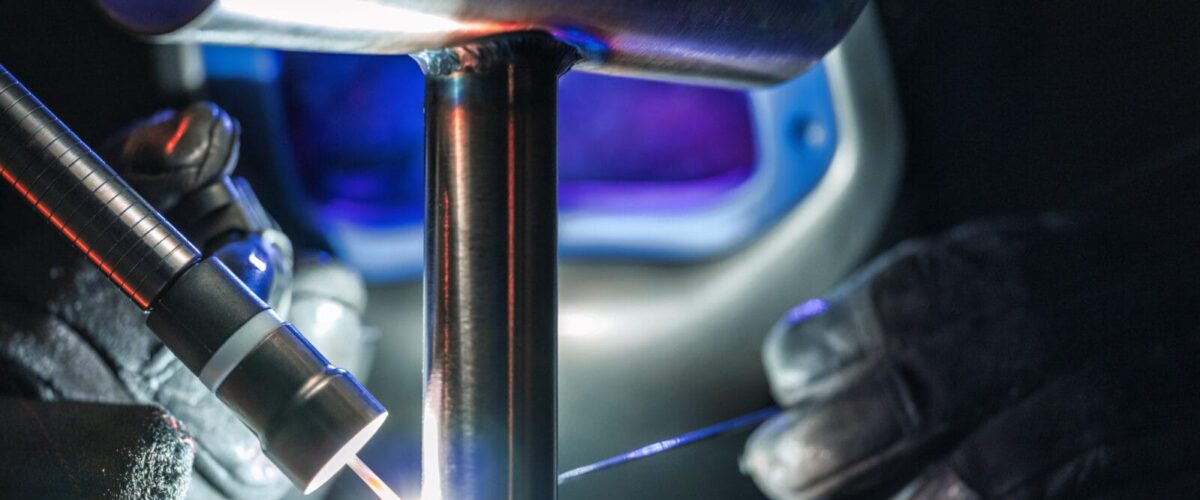

Another common welding process is GTAW, or TIG (Tungsten Inert Gas) Welding. This method requires a more experienced and skilled welder, as the manual technique of applying a filler metal to create the weld joint, while utilizing the equipment, is quite complex.

However, the complexity of this procedure also offers more precision than MIG Welding. If done correctly, TIG Welding provides a very clean and high-quality weld. Material requirements are similar to MIG, with thin steels, copper and aluminum working best with this process.

Applications are much broader, as the precision capabilities allow for more high-end welding to be done. TIG Welding is often used for welding art for example, due to the small details that can be applied. Mission-critical industries like Aerospace can rely on this procedure too, for precision, thin-metal welding, as can industries like food processing or pharmaceuticals.

Submerged Arc Welding

Functioning differently to MIG and TIG, SAW is primarily an automated method of welding. Sub-Arc Welding isolates the arc zone below the surface of a granular flux, which eliminates any contamination to the atmosphere. It uses a continuous feed of consumable Welding Wire, in either a single or multiple alloy/wire combination.

As opposed to the capabilities of MIG and TIG, SAW can handle much thicker welding materials. The same group of alloys are applicable, although nickel and other high-strength alloys can also be welded this way.

Heavy-duty industry applications including ship building, pipeline construction, pressure vessels, and large-scale structural work will often require the capabilities of Sub-Arc Welding. It is best applied for long, continuous welds of thick, strong metals.

Quality Control and Industry Conformance

We understand the many needs of the modern consumer, beginning with reliability. Our innovation and precision have allowed us to become a manufacturer with the ability to consistently meet tight tolerances and specifications for our customers.

Quality and Testing are two things that our company takes very seriously. With our Generation4™ Welding Wire, we provide all of the information you need to trust our products. All of our Welding products are supplied with a certificate of conformance, stating physical and mechanical properties including alloy chemistry.

Another advantage of our Welding Wire is the opportunity for full lot traceability for every welding product. Each product is manufactured with its own unique lot identification number, tracing its manufacturing journey. Learn more about why this is important in our lot traceability blog here.

Relying on CWI for Your Welding Wire Alloys

As Welding industry experts, we know the various requirements that your project may present, and we have the resources to meet them. When the highest levels of safety and quality are needed, choose Central Wire for all your Welding Wire consumables.

No matter your packaging needs, alloy requirements, or wire size demands, we are ready to meet your specifications. Request a Quote today to find the perfect Welding Wire solution for your next project.