As a multi-faceted manufacturer, the Central Wire Group of Companies is uniquely positioned to deliver custom manufacturing y wire solutions that meet the most demanding global standards. With facilities across Canada, the USA, and the UK, we provide a blend of domestic support and global manufacturing capabilities, giving our customers sourcing stability, reduced lead times, and confidence in the consistency of every order.

En premium stainless alloys a nickel alloys, our product portfolio ensures precision and durability in mission-critical industries worldwide. Whether you are sourcing raw wire materials for a one-time project or securing a long-term partnership for global supply, we offer the capabilities and quality assurance that only an industry leader can deliver.

Global Manufacturing Facilities and Buying Options

In today’s interconnected economy, sourcing challenges and supply chain uncertainty remain at the forefront of manufacturing concerns. By partnering with Central Wire, you gain the advantage of global manufacturing facilities paired with flexible order structures designed to support both short-term and long-term needs. Global Quality Backed by Local Support

We accommodate:

- Prototypes for research and development.

- Bulk orders for high-volume applications.

- Scheduled deliveries for consistent supply chain stability.

With this versatility, our customers avoid the risks of juggling multiple vendors while gaining access to a reliable partner that delivers both product consistency y supply chain resilience.

Custom Products to Suit Your Precise Requirements

With over six decades of wire manufacturing experience, we understand that each project requires unique solutions. Our global operations allow us to match specific application requirements with the right alloy, profile, and finish.

- Customizable for density, rigidity, flexibility, and strength.

- Manufactured from stainless alloys, nickel alloys, or specialty metals.

- Used in filtration, separation, and mist elimination with options for bulk mesh or custom demister pads.

- Manufactured from nickel, stainless, and premium specialty alloys.

- Available in multiple regular and custom profiles.

- Four distinct edge configurations for precise mechanical performance.

- Offered in corrosion-resistant alloys such as stainless steel, nickel, and copper.

- Four economical coating options for enhanced finish and long-term performance.

- Manufactured to tight tolerances to ensure consistency in demanding applications.

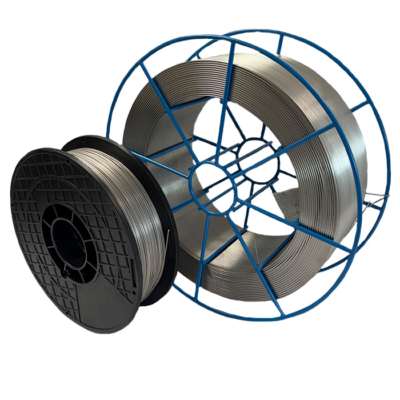

- Nuestra Generation4™ Welding Wire line supports MIG, TIG, and SAW welding procedures.

- Proven to deliver consistent arc stability, reduced spatter, and improved weld quality.

- Manufactured in North America, ensuring shorter lead times y domestic availability.

This breadth of products demonstrates our ability to scale from custom manufacturing for specialized projects to high-volume production for industrial requirements, all without compromising quality.

In-House Testing Procedures

Quality does not stop at production. Every order is backed by robust in-house testing and validation processes. Our ISO-certified facilities employ:

- Non-destructive testing to verify structural integrity without compromising performance.

- Mechanical testing for tensile strength, elongation, and hardness.

- Metallurgical analysis to confirm alloy chemistry and consistency.

These procedures ensure every coil, spool, or length of wire meets the strictest requirements before it leaves our facilities, reinforcing our reputation as a global leader in precision wire manufacturing.

More than a Manufacturer

Central Wire Group is more than just a wire supplier—we are a long-term partner in your success. Our global presence and deep engineering expertise provide:

- Research and Development Support – Innovation for new alloys, finishes, and profiles.

- Engineering Consultation – Application-specific advice from experts with decades of experience.

- Supply Chain Stability – Mitigating sourcing challenges with multiple global facilities.

- Custom Manufacturing – Tailored solutions to match your exact application requirements.

Whether you are a multinational organization needing consistent, large-scale sourcing, or a smaller operation requiring highly specialized wire, our adaptability and technical support ensure reliable solutions that protect your bottom line.

Trusted by Industry Leaders Worldwide

For over 60 years, Central Wire has supplied premium alloys and custom wire solutions to industries including:

- Aerospace & Defense

- Medical Device Manufacturing

- Petróleo y gas

- Automotive & Heavy Equipment

- Industrial Filtration

- Construction & Infrastructure

This global reach is built on one foundation: commitment to quality at every stage of manufacturing. As recognized industry leaders, we continue to evolve with the needs of our customers, offering both the durability of stainless alloys and the performance of nickel alloys in critical applications.

Why Choose Central Wire for Your Wire Manufacturing Needs ?

- Global manufacturing footprint across North America and Europe.

- Flexible lead times and order sizes to match your project timeline.

- Extensive alloy selection for maximum durability and application fit.

- Proven supply chain reliability with domestic and global delivery options.

- Dedicated to providing customer satisfaction through engineering support and long-term partnerships.

By choosing Central Wire, you are not just sourcing material—you are securing a relationship with a global leader in wire manufacturing.

Ready to explore how Central Wire can help solve your sourcing and supply chain challenges with premium quality wire solutions?

Contact our sales team at sales@centralwire.com or visit centralwire.com to explore our full range of products and capabilities.