Today’s specialty metals can work well in any environment, strain, or temperature. Despite harsh demands of different environments, there are plenty of high temperature resistant alloys available! As industries around the world push for higher and higher levels of performance in their materials, metallurgists continue to develop new and exciting alloys to meet today’s challenges.

Temperature presents a unique challenge when working with metals — the ability to select alloys that can maintain their strength and yield during high heat applications, but that are able to be processed in temperature ranges that make them viable for use in industry. If you are developing solutions that require operation in a challenging high temperature environment, take a moment to review the choices below., and discover what alloys can withstand high temperatures.

High Temperature Resistance Alloys

Inconel® 600 is a versatile nickel-chromium alloy which can withstand temperatures all the way up to 2000°F. This alloy contains a lot of nickel. This makes it resistant to corrosion from organic and inorganic compounds. It also resists corrosion from alkaline solutions. The chromium content gives resistance to various sulfur compounds and oxidizing environments.

People use this alloy in applications such as:

- Furnace Seals, Fans and Fixtures

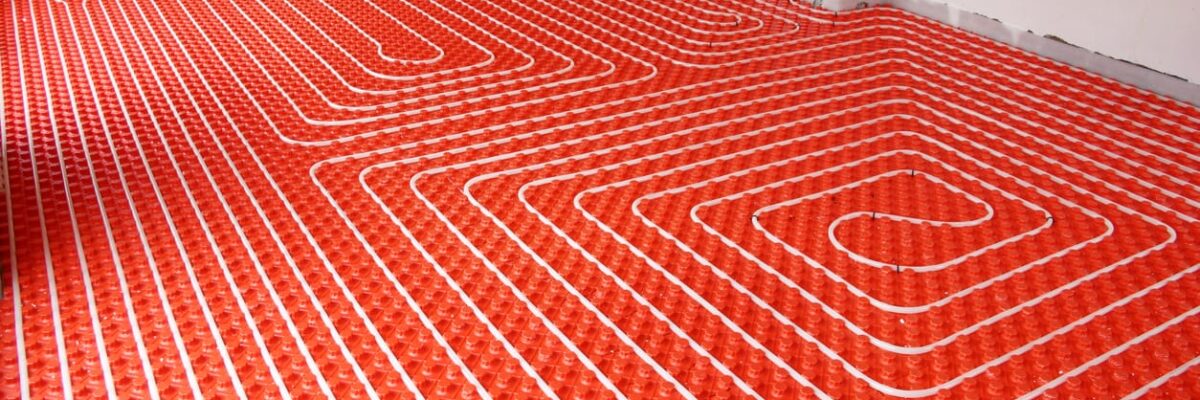

- Heated Flooring

- Chemical and Food Processing

Inconel® 601, like Inconel® 600, consists mainly of nickel and chromium in its structure. The latter is more common than the former because it has more applications.

601 possesses more antioxidant properties, than 600, thus it is used in different applications like:

- Fabricated Combustion Chambers

- Strand Annealing Tubes

- Rotary Kilns and Calciners

Inconel® 718 is an alloy made of nickel, chromium, and molybdenum. It has excellent mechanical properties at both high and low temperatures. Works well in temperatures from -423°F to 1300°F, and can resist oxidation up to 1800°F.

In terms of applications, Inconel® 718 is suitable for:

- Gas Turbine Components

- Cryogenic Storage Tanks

- Jet Engines

Hastelloy X® is a nickel-based alloy with high strength and oxidation resistance up to 2200°F. Beyond that, it possesses a high resistance to stress and corrosion cracking in petrochemical applications.

This alloy can withstand high temperatures and resist oxidation and neutral atmospheres, preparing it for use in applications such as:

- Furnace Applications

- Gas Turbine Engines

- Cabin Heaters

35-19Cb

CWI Nickel Prime Series 35-19Cb is an austenitic nickel-chromium alloy, with addition of niobium (columbium). It is characterized by its high mechanical strength, and is suitable for furnace temperatures up to 2012°F. Its main application use is as wire in mesh belts.

330

CWI Nickel Prime Series 330 is also an austenitic nickel-chromium-iron-silicon alloy that offers excellent oxidation as well as carburization resistance up to 2200°F. The high nickel content makes this alloy resistant to chloride stress corrosion cracking, like Hastelloy X®. This unique alloy is featured in applications like:

- Power Generation

- Heat Treatment

- Furnace Parts

Unlike all the other alloys featured, L605 is a cobalt based alloy. It can provide continuous service up to 1800°F and good strength to 2150°F. L605 can withstand oxidation up to 1900°F and is also resistant to hydrochloric acid, nitric acid, and wet chlorine. Due to its resistance to corrosion in very severe environments, this alloy is used in applications such as:

- High Temperature Ball Bearings and Bearing Races

- Gas Turbine Engine Combustion Chambers and Afterburners

- Heart Valves

CWI and Our Resistance Wire Options

These 6 alloys answer one of our biggest questions: what alloys can withstand high temperatures? In the pressing industries of our modern world, trust our metal alloys to get the job done.

Whether your application is manufacturing of furnaces, ovens, other appliances or even jet engines, CWI provides the resistance wire alloys you need! For temperatures far below freezing, or above 2000°F, there are alloys that can handle it! For more information on our products, or to request a quote for resistance wire, visit our product page here!