BENEFITS

Using CWI products in your build offers many advantages.

- Corrosion-resistant: Copper wiring is not subject to galvanic corrosion when connected to other metals and alloys.

- Conductivity: Copper is more efficient than any other electrical conductor. Using this alloy for construction requires less insulation and smaller conduits than aluminum.

- Malleable: Copper is strong and resists stretching, neck-down, creep, nicks and breaks. Avoid fatigue failure and select a malleable and ductile alloy.

APPLICATIONS

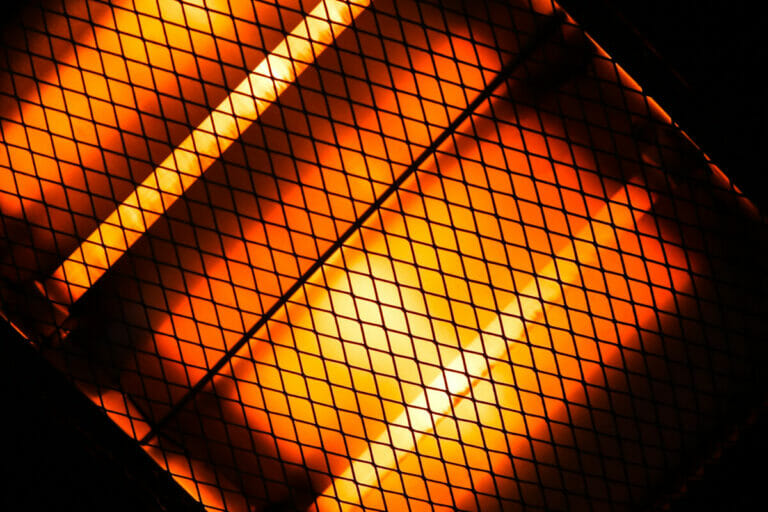

- Power Generation: For large appliances like furnaces and ovens, consider an efficient copper wire cable construction.

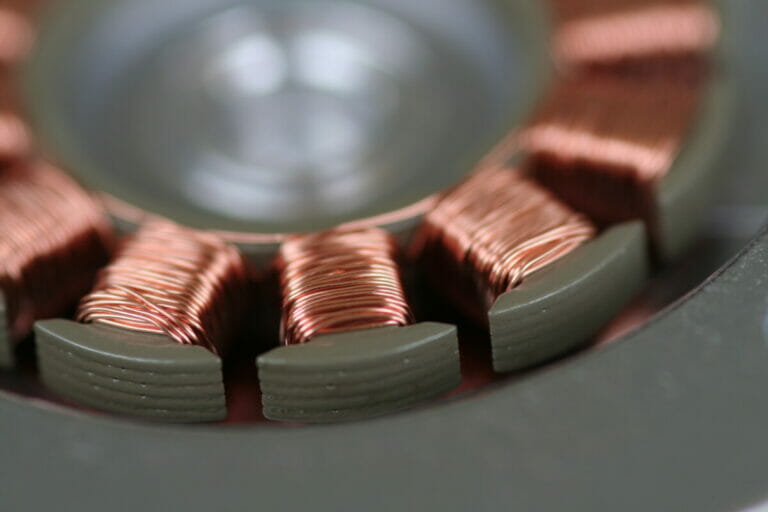

- Electronics Circuitry: Red metals alloys are used to make electrical contacts, from lighting to HVAC.

- Telecommunications: Copper is responsible for moving data and throughout a building or home and linking to telecommunications and cable networks.

PRODUCTS

Filo sottile

CWI manufactures copper wiring electrical fine wire in dimensions from 0.001” (0.0254mm) up to .032” (0.0812mm). It is known as the conductor of choice in wiring systems throughout the construction industry. Need help outfitting a new build? Contact a salesperson to supply your building’s red metals.

Filo di resistenza

For extremely high-temperature construction applications like heat-treating ovens and furnaces choose a CWI resistance wire. This type of wire has high resistivity, which makes it better for short wire to convert electrical energy into heat. These ovens can be used to treat a variety of metals and glass to harden or soften a material through extreme heating and chilling. CWI resistance wire is available in several copper alloys. CWI manufactures resistance wire from: 0.001″ (0.0254mm) up to .0808” (2.052mm).