The oil and gas industry can be taxing, on not just workers but on products as well. Any materials being used need the appropriate qualities to withstand the harsh conditions of this industry.

Materials need to withstand conditions like extreme temperatures, harsh corroding chemicals, and the physical pressures of the industry.

From downhole applications to repair products, oil filtration system materials and more, Central Wire Group of Companies offers a wide array of products for effective use in the oil and gas industry. Look to CWI: serving the entire oil and gas industry, for your next solution.

Continue reading for more information on some of the critical components and products for the oil and gas industry, and what makes each one the right choice every time.

Oil and Gas Slicklines

The CWI GD™ – SUPA® Slicklines can handle the harshest of oil, gas, & geothermal conditions, both on-shore and off-shore. Slicklines are high-strength cables used for various downhole operations in the oil and gas industry. They typically are deployed to convey tools and equipment into wellbores without needing an expensive workover rig.

The CWI GD™ – SUPA® Slicklines are engineered for oil, gas, and geothermal applications. Our slickline is manufactured in the USA from alloys designed to provide a continuous, weld-free, bright finish wireline available in a variety of lengths up to 40,000 feet.

We produce corrosion-resistant lines designed to go downhole in sour and sweet environments. With eight material alternatives to choose from, our GD™-SUPA® slickline can handle harsh conditions while maintaining the performance levels you need.

Our slickline services for precision downhole operations can be compliant with EN10204 standards when required.

Available Alloys

- GD316 (UNS S31600)

- GD22 (UNS S31803)

- SUPA 40 (UNS S31803)

- GD31Mo (UNS N08926)

- SUPA 75 (UNS N08926)

- GD35Mo (UNS N08028)

- GD37Mo (UNS S31277)

- GD39Mo (UNS N08031)

- SUPA 80 (UNS N08031)

- GD50 (UNS R30035)

- GD100 (UNS S32760)

Tech-Mesh™ Products

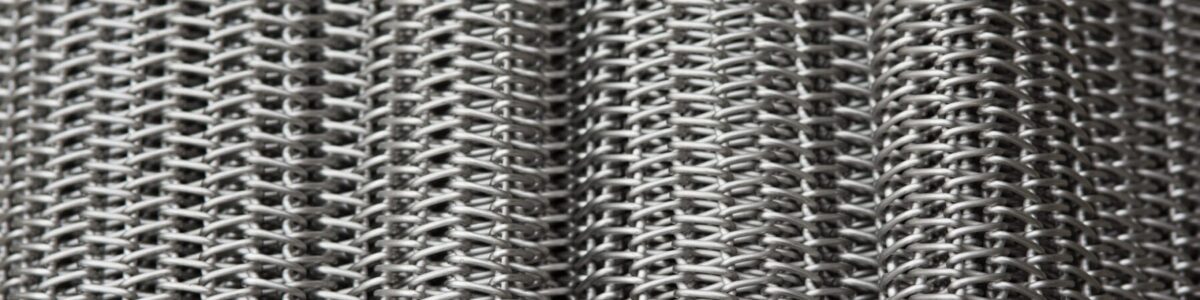

At CWI, our Tech-Mesh products refers to two product lines: custom demister pads and knitted wire mesh. Both product lines cater to the demands of the oil and gas industry with strength and durability. Here is a brief explanation of both, manufactured with the excellence and reliability required for filtration applications.

Knitted Mesh

Our knitted wire mesh is an efficient, economical, and reliable product for filtering liquids in oil refineries, chemical processing, and a wide range of other applications. Knitted on state-of-the-art equipment under strict quality control processes, our mesh maximizes separation efficiency and minimizes pressure drop. The knitted wire mesh is made from individual wires, either interlaced or knitted together, and is very flexible.

In oil and gas applications, knitted mesh is typically used when minimizing pressure drop is crucial. Its physical flexibility allows versatility in applications with non-standard or irregularly shaped equipment.

Demister Pads

Our custom demister pads, or mist eliminators, play a similar filtration role with a different construction. Our demister pads come in round, rectangle, ring or custom shape designs, and can be custom sized to the consumer’s needs. They can be designed as one unit or individual sections, depending on the size of the finished product. Many larger demister pads will also have top and bottom support grids.

Demister pads filter liquid and gases effectively, removing hazardous mist often right at the top of a distillation column. Constructed from premium stainless steel, copper, or custom alloys, our custom demister pads provide consistent filtration performance in harsh conditions.

All of our core products are produced in-house, and our finished mist eliminators are always manufactured in the USA through our Houston, Texas facility. We offer a wide range of alloys beyond traditional 300 series stainless steel, including Alloy 625 and Alloy 718. Whether you need Monel® 400 bulk mesh or a custom Nickel 200 demister pad, our knitted wire mesh products are always manufactured according to our customers’ unique specifications.

Available Alloys

- Stainless steel

- Nickel

- Specialty

End-Use Applications

- Mist elimination

- Chemical processing

- Filtration

Shape Options

- Round

- Rectangular

- Custom

Welding Wire Product Line

Looking to perform routine maintenance on chemical or petroleum processing equipment? Planning turnaround repairs or a plant shutdown and seeking an alternative supplier to simplify your purchasing process? Look no further than Central Wire Gruppo di aziende filo di saldatura. By ordering all your turnaround supplies from CWI, you can reduce downtime, perform maintenance all at once, and work confidently knowing you are receiving only the highest quality products from a trusted manufacturer.

CWI: Serving the entire oil and gas industry.

Packaging Options

- Reels

- Spools

- Drums/Drum Packs

- Tubes

Welding Types

- Tungsten Inert Gas (TIG) Welding

- Metal Inert Gas (MIG) Welding

- Submerged Arc (SAW) Welding

Leghe

- Stainless steel

- Nickel

- Copper

Profile/Shaped Wire

Wedge shaped wire, also known as triangular wire or V-wire, is a common choice for filtration screens. Filtration screens are made by welding lengths of shaped wire to support rods that add structure and rigidity.

By changing the spacing between the wedges or adjusting the size of the shapes, these screens can be highly customized to meet the needs of different applications.

Typically manufactured using 300 series stainless steel or Inconel® alloys, these heavy-duty screens are engineered to withstand the most demanding environments and conditions.

Leghe

- Stainless steel

- Nickel

- Specialty

Tolerances

- +/-0.0015” to +/-0.00025”

Wire Diameter

- 80mm – 18.00mm (0.031in – 0.709in)

Central Wire Group of Companies in the Oil and Gas Industry

CWI: Serving the entire oil and gas industry.

Central Wire helps take the stress out of turnaround season! Whether you need shaped wire for filtration screens, knitted wire mesh for mist eliminators, slicklines for downhole operations, or welding wire for general repairs, we have all the supplies you need in one place. Visit our product pages qui or contact us today at [email protected] with any additional questions!