As a multi-faceted manufacturer with many locations and product lines, we are able to offer many benefits to our customers. From customization requests to short lead times, the perks of choosing CWI go far beyond our premium raw materials.

Our quality assurance is also second to none, with multiple testing options readily available which confirm the durability and reliability of our products. Whether it be destructive or non-destructive testing, we are able to ensure the quality of our products meets your expectations.

With that being said, we know that the importance of accountability goes far beyond these offers, which is why we manufacture every welding product with its own unique lot identification number for full lot traceability.

Continue reading below to discover the importance of full lot traceability, and what it means for our Welding Wire product line.

What is Full Lot Traceability?

In manufacturing, full lot traceability creates accountability along every step of the process from raw material distributor to a products end-use application.

A group or “lot” of products that were made together in the same production run, with the same materials, are assigned identification labels which can then be tracked.

Lot traceability applies to raw materials, finished goods and everything in between, with the prime objective being a batch of manufactured products that are traceable at every stage of the production process. Lot traceability is extremely efficient because it is bi-directional, meaning you can track back upstream to a raw material provider and manufacturer or downstream to distributors and end-use customers.

Importance of Full Lot Traceability

Having this ability to track products through their entire manufacturing and production process not only allows easy sourcing should there be some sort of product defect, but also builds trust and accountability down the entire production chain.

Quality Control

You’ve seen it before, a product recall due to a defect or other issue. Commonly you may see this with cars or food products, but it can happen within any industry. These recalls can create panic and confusion, wondering how or why a product could have such an issue.

With full lot traceability, the confusion is eliminated. Products can be traced to whichever stage the issue occurred in, facilitating problem resolution and improving overall quality.

Compliance

When manufacturing for certain sectors like Aerospace or Automotive there are many regulations and quality assurance requirements. This traceability can ensure that the raw material manufacturer meets the industry standard and regulatory requirements for these industries.

Accountability

The clear record of every aspect of the Welding process increases accountability between manufacturer, distributor and end-use customer. Promising quality and durable raw materials is one thing but having your product traceable to you ensures accountability and responsibility for manufacturing consistently to that level of quality.

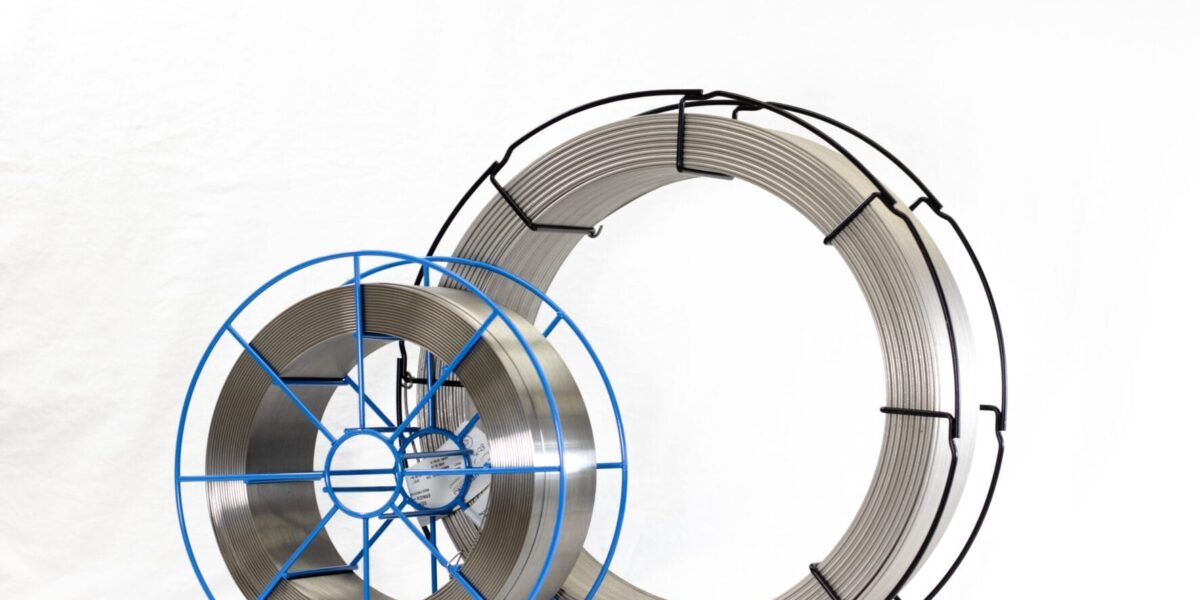

Traceability of our Generation4™ Welding Wire

Our Welding Wire product line boasts excellent versatility and quality, covering many Welding Types and ensuring your projects and repairs last even in harsh conditions.

We also have the necessary resources to help you choose the right alloys, and Welding Procedures for your project. This includes our Welding Types Information Page and our Recommended Welding Procedures Page.

We show our confidence and expertise in this product line by providing full lot traceability for all Welding Wire products, along with certificates of conformance stating physical and mechanical properties including alloy chemistry. What you see is what you get with Central Wire!

Contatto

As a manufacturer with years of experience in a huge range of product lines and industries, we know what it means to build trust with your customers. Consistent manufacturing quality, with the testing capabilities and raw materials we provide goes a long way in building trusting relationships with customers.

However, we want the added accountability with our Welding Wire product line, with full lot traceability ensuring at any point in the production chain, the materials can be traced back to our manufacturing plants. That’s how confident we are in what we do!

If you have any additional questions about our Welding Wire products, or want to learn more about any of our other manufacturing capabilities, contact our sales team at sales@centralwire.com.

If you want to learn more about our Generation4™ Welding Wire product line and capabilities, visit our product page today here.