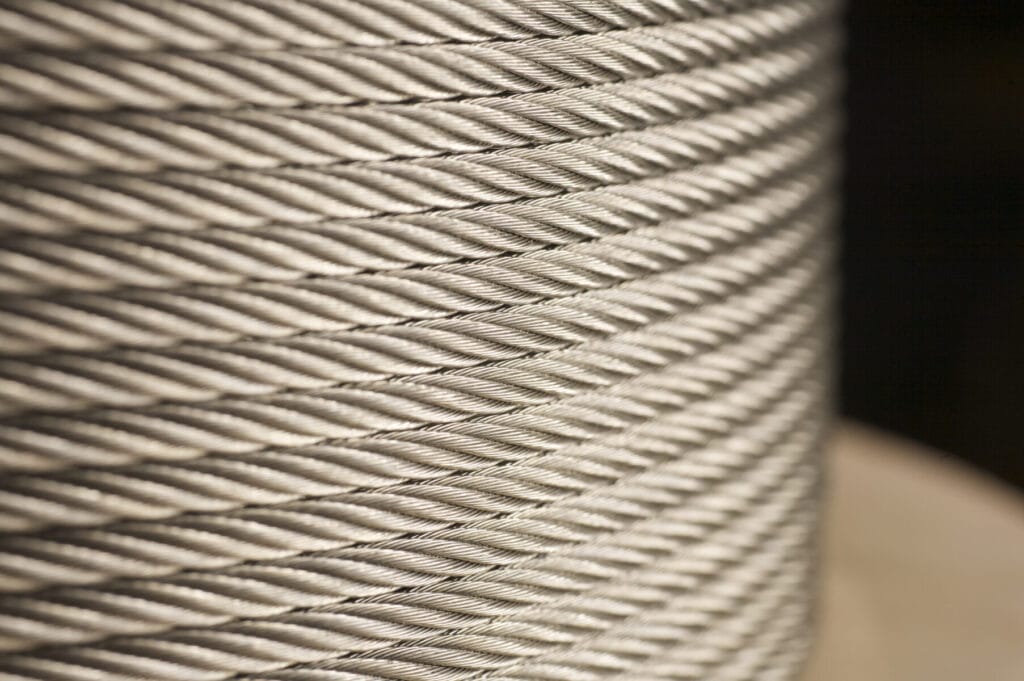

As a Wire Rope manufacturer, it is crucial to provide material versatility to customers, whose project needs can change depending on their specifications and their industry. Not all projects are built the same, and at Loos and Company, we are up to the task no matter the scope of your next project.

Our Wire Rope product line shows this versatility, with multiple sizes, constructions and materials available depending on your requirements. Whether your project is focused on aesthetics, flexibility, strength or durability, we are able to provide the right solution.

Choosing a Wire Rope Material

Being aware of the benefits and common applications of each material we offer in our Wire Rope product line ensures your specific requirements are met.

Continue reading to explore the benefits and applications of each material option in our Wire Rope product line.

Galvanized Steel:

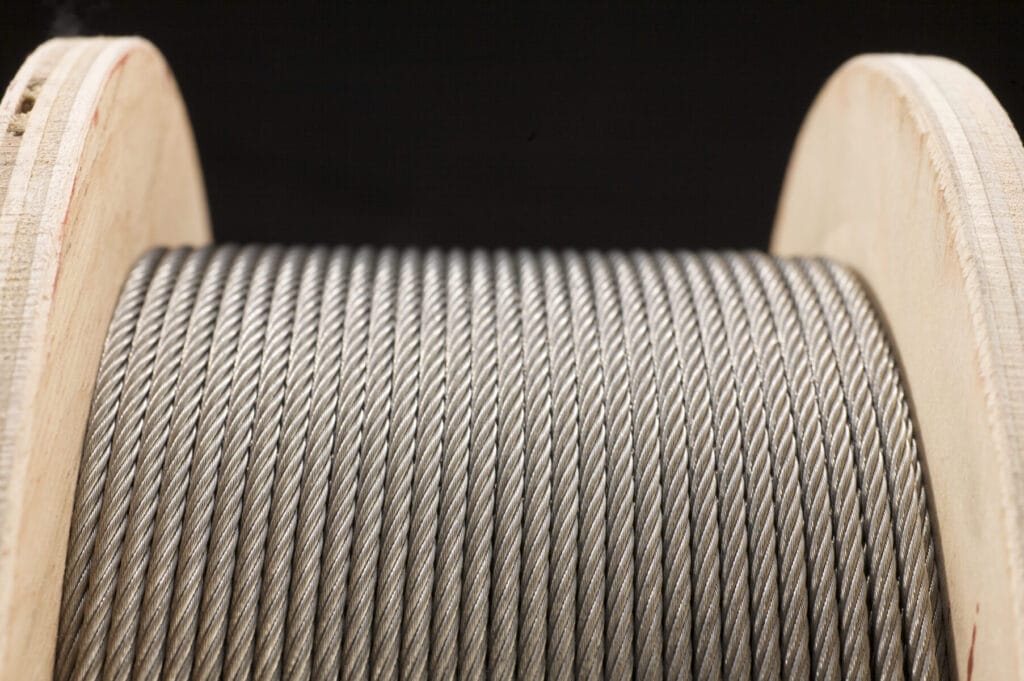

Choosing Galvanized Steel Wire Rope promises a versatile, strong and durable product. Available in 6×19, 6×37, 7x7x7, and 7x7x19 constructions, Galvanized Steel provides consistent performance in logging, rigging, hoisting and general industrial applications. The material consists of zinc-coated carbon steel and is only available in commercial grades. Some of the key features and shortcomings of this material include:

- Typically possesses a higher breaking strength than Stainless Steel

- Remains ductile over years of use

- Fairly flexible

- Minimal resistance to corrosion

Stainless Steel:

Stainless Steel is consistently one of our most sold materials. Alloy 302/304 is our most common, but some constructions of our Wire Rope and Cable are available in 305 and 316 as well. Notably, Stainless products can handle the difficult environmental conditions of industries like Mining and Oil and Gas. The main strengths and weaknesses to consider when choosing Stainless Steel Wire Rope include:

- Excellent corrosion resistance, and can resist damage from saltwater and moisture

- High levels of strength

- Hard-wearing material

- Oxidation and chemical resistance

- Less flexible than Galvanized Steel

Bright Carbon Steel:

Available in both Independent Wire Rope Core and Fiber Core options, Bright Carbon Steel Wire Rope can provide a range of flexibility and strength. This material is only available in 6×19 and 6×37 constructions, and in commercial grades. Common end-use applications include crane hoisting, rigging, and general industrial applications. The notable features of Bright Carbon Steel Wire Rope include:

- High levels of strength

- Very flexible material

- Cost-effective option

- Does not protect against corrosion unless additional lubrication of coatings is added

Domestic Manufacturing

With every product line we manufacture, we pride ourselves on the Domestic Manufacturing standards that we meet. We are able to produce consistent, high-performing products for our customers right here in the United States. These standards include:

- Domestic Wire Rope – Ensures that Wire Rope is stranded and closed in the USA

- 100% Domestic / Buy America Act – 100% of a product must be manufactured in the USA

- Buy American Act – The cost of product supplies manufactured outside of the USA must not exceed 50% of the total price of the final product

- Made in USA – “all or virtually all” of a product has been made in America, significant parts, processing and labor included

We also possess multiple Military Specifications for our Wire Rope products, for aircraft control among other applications. Check out our Government Sales page qui for more on our military capabilities!

Choosing us as Your Wire Rope Supplier

No matter your material and project needs, we are the right choice for your next Wire Rope purchase. Our Domestic Manufacturing process confirms the quality control and precision you expect from a manufacturer.

Learn more about our Wire Rope product line, and how we can meet the specifications of your next project on our product page today!