Longevity is the ability of a product to deliver stable, repeatable performance over time—years of cycles, loads, stress, and exposure without losing integrity. At Central Wire, longevity isn’t an attribute assigned after the fact. It’s engineered deliberately into the materials, the construction, and the quality systems behind our Wire Rope e Bar Stock.

These two product families serve different functions, but both demonstrate the same philosophy: build to endure first, and everything else follows.

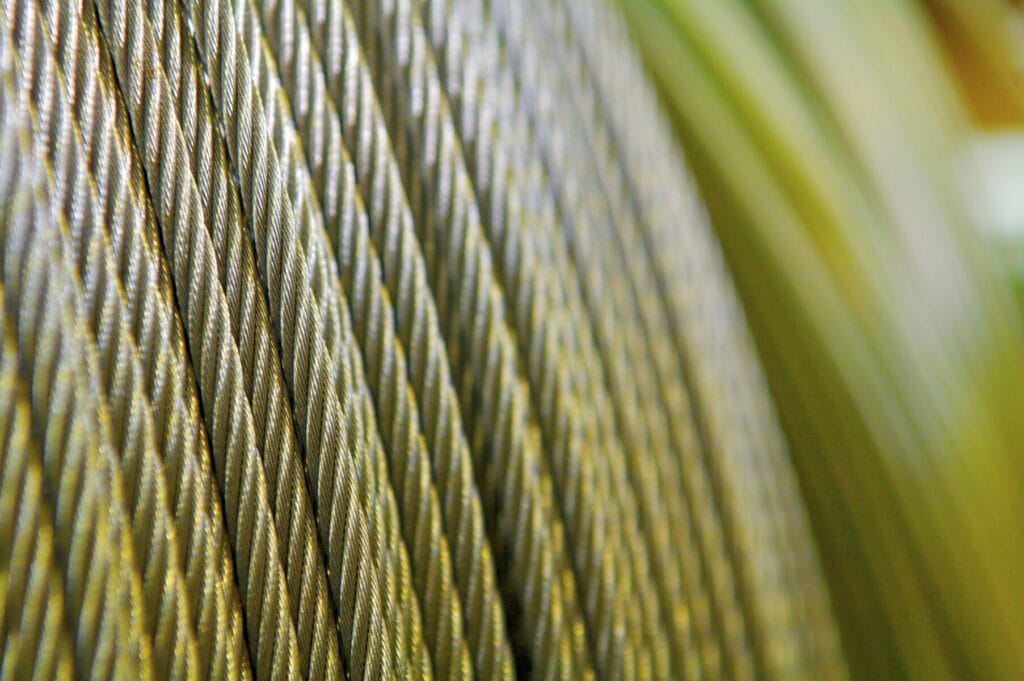

Wire Rope Designed for Long Service Life

Wire Rope is among the most stressed components in an industrial system. It lifts, supports, guides, restrains, and moves loads around the world—often continuously and under demanding conditions. Its longevity depends on decisions baked into its design.

Material choice is the starting point. Stainless Steel constructions provide long-term corrosion resistance in Marine and Architectural environments. Specialty alloys extend fatigue life in Aerospace and Industrial equipment. Controlled wire drawing and strand alignment ensure each layer distributes load evenly, preventing premature wear.

Longevity comes from predictable performance under real-world conditions. The rope must maintain flexibility without losing strength, resist corrosion without maintenance cycles, and withstand bending fatigue across thousands of load iterations. Central Wire achieves this through tight process control, consistent metallurgy, and manufacturing methods refined over decades.

Across Aerospace flight controls, Marine rigging, Industrial cranes, Architectural tension systems, and lifting equipment, Wire Rope longevity is the difference between reliability and risk.

Bar Stock: Longevity Through Metallurgy and Consistency

If Wire Rope’s longevity is defined by movement, Bar Stock’s longevity is defined by stability. Every fastener, bolt, machined part, and formed component made from our Bar Stock starts with the integrity of the material itself. Mechanical performance over years of use is determined long before a part is machined or cold-headed—it begins with alloy chemistry, microstructure, and dimensional accuracy.

Central Wire ensures these foundations are correct from the start. Alloy chemistries are verified before production, and mechanical properties are validated through tensile and hardness testing. Dimensional consistency ensures that customers machining precision components or forming high-volume fasteners can rely on stable performance from lot to lot.

Longevity for Bar Stock means components resist wear, deformation, and corrosion through years of operation. Whether it becomes a precision Aerospace component, an Automotive fastener, or an Industrial machine part, the stability of our Bar Stock ensures predictable, long-term performance.

The Metallurgical Science in Longevity

Both Wire Rope and Bar Stock rely on a shared backbone: metallurgy. The way metals respond to stress, temperature, corrosion, and mechanical forces over time determines their life cycle.

- Stainless grades extend lifespan in corrosive or outdoor environments.

- Controlled grain structure improves fatigue life in cables and precision parts.

- Specialty alloys maintain integrity under high temperatures or chemical exposure.

- Consistent tensile properties prevent early failure in both rope and fasteners.

Longevity is not a single feature—it’s an engineered outcome from the raw material level onward.

Longevity Verified Through Testing

Longevity cannot be claimed; it must be demonstrated. That’s why Central Wire validates both Wire Rope and Bar Stock through rigorous destructive and non-destructive testing.

Wire Rope undergoes tensile testing, fatigue cycling, bend analysis, and visual inspection. Bar Stock is tested for hardness, tensile strength, dimensional stability, and microstructural integrity. These tests ensure each product line performs predictably not just when new, but across the full life cycle customers expect.

Testing is ongoing. Longevity is not a one-time certification—it’s a continuous confirmation that every batch, every coil, every reel meets the same standard.

Consistency Across Global Facilities

Longevity relies on consistency. With facilities in the United States, Canada, and the United Kingdom, Central Wire applies unified quality systems so that Wire Rope and Bar Stock meet the same standards no matter where they are produced. The longevity customers experience in one region is the same in another—because the processes behind the products are aligned.

This harmonization reinforces longevity by removing uncertainty from the supply chain. When customers reorder, they receive the same metallurgy, same performance profile, and same life expectancy—order after order, year after year.

Built to Last, Designed to Perform

Longevity is engineered, tested, and proven. Central Wire’s Wire Rope and Bar Stock deliver life cycles that align with the demands of Aerospace, Automotive, Marine, Construction, and Industrial sectors. These products endure because they are designed with longevity as the first requirement—not the last.

From corrosion resistance to fatigue behavior, from tensile stability to dimensional accuracy, longevity is embedded into every step of production. That’s why industries with the highest expectations continue to rely on Central Wire for materials and systems that perform long after installation.

Longevity in Real-World Use

The true measure of longevity is how products behave outside the factory.

Wire Rope maintains function in environments that test metal to its limits—saltwater exposure, vibration, temperature swings, and repeated mechanical loading. Bar Stock remains stable after machining or cold heading, delivering fasteners and components that hold tolerances and strength over years of operation.

Whether it’s a control cable in an aircraft, a Marine lifting line, a critical Industrial fastener, or a precision-machined part, Central Wire materials prove their longevity in the environments that matter most.

Next Steps

Explore our Bar Stock e Wire Rope to see how Central Wire delivers accountability through testing, certifications, and products built to last.

For project guidance or to request a quote, contact our team today at sales@centralwire.com