Building on our expertise in knitted wire mesh and custom demister pads, we are excited to announce the expansion of our product offerings to include Structured and Random Packing solutions.

Choosing the correct Packing Solution for your Oil & Gas Operation is crucial to the integrity of the vessel and process. Our Packing options are designed to optimize your oil & gas production and profits.

Mass transfer efficiency can be greatly improved by the use of Structured or Random Packing. Whether your project entails midstream, chemical, refinery or distillation columns, we have the solutions you need.

Embalaje estructurado

Superior Performance and Long-Lasting Quality

Our Structured Packing solutions are engineered for superior performance, offering optimal pressure drop and efficiency characteristics. Ideal for distillation processes, these packings ensure excellent liquid and vapor distribution, which is crucial for high-capacity and high-purity applications.

Key Features:

- High surface area for improved mass transfer

- Reduced pressure drops across the column

- Enhanced separation efficiency

Types of Structured Packing:

Gauze

Gauze structured packing is specifically engineered for distillation processes requiring fine control, particularly in chemical industries with low liquid rates. This type of packing is ideal for applications where maintaining a high level of separation efficiency with minimal resistance is crucial.

Knitted

By knitting wire into a high-density mesh, the packing provides high mass transfer efficiency that maximizes surface area and promotes efficient vapor-liquid contact. Compared to gauze, knitted mesh transfers mass at a higher pressure drop. Knitted packing is suitable for refining, petrochemical, and gas absorption processes.

Grid

Grid structured packing is primarily used for robust performance in processes prone to fouling. It features either corrugated or bladed grid configurations that allow it to handle solids and dirty streams better than other types of packing. In industries with clogging and high operational demands, grid packing is a great choice for your packing solutions.

Sheet Metal

Consisting of corrugated metal sheets oriented at an angle, enhancing contact between the vapor and liquid phases, Sheet Metal packing improves mass transfer efficiency and reduces pressure drop across the column. The packing is suitable for both low and moderate pressure applications.

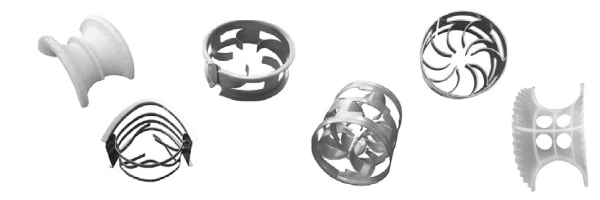

Random Packing

Versatile, Robust Performance

Random Packing is your go-to option for versatile, robust applications where durability and cost-effectiveness are key. Random Packing is suitable for a wide range of applications, offering flexibility and reliable performance under various operational conditions.

Key Features:

- Cost-effective solution for mass transfer applications

- Strong resistance to fouling

- Easy to handle and install