In terms of economic impact, workforce size and environmental impact, the Aerospace industry is a robust force. According to RFGen, the industry contributes more than 1.65% to the total U.S. GDP each year, which is about $418 billion in economic value, with the industry also employing more than 2.1 million workers.

The sheer size and mission critical nature of this industry demands efficiency and consistency, to keep this massive financial cycle moving and to keep planes, commercial and cargo, safe.

From new fuel efficiency measures on-board aircraft to the innovative ways of making Aerospace manufacturing smoother, continue reading to learn how this industry is evolving, and the ways our Group of Companies continues to support it.

Aerospace Efficiency Priorities and Challenges

The constant innovation in this industry is necessary to keep up with new and improved technologies, and competitors working to maximize their efficiency and profits. The size and mission-critical nature of this industry creates a need for quick turnarounds on custom, durable products.

Improving efficiency in Aerospace manufacturing is one of the best ways to separate from the fierce competition of this industry. Learn more below about the technological advancements and manufacturing solutions that have led to more efficient Aerospace manufacturing, as well as increased fuel efficiency.

Custom Manufacturing

One of the ways Aerospace has become more innovative in its processes is by using custom manufacturing methods. These include additive manufacturing such as 3D printing, or subtractive manufacturing such as our CNC Machining. Both methods create custom, precise products that can meet tight tolerances. The streamlined digital design of custom components helps to create faster production styles while allowing full customization of size and shape characteristics.

Efficient Engine Technology

A major component of the efficiency push in this industry is creating more efficient and effective avión engines. These new advanced engine technologies can operate at peak efficiency for long periods of time and also help limit carbon emissions. The changes in engine design include lighter material options, or new designs altogether such as Turbofan or Bypass engines, which in different ways allow more air to pass through them, creating thrust while limiting fuel consumption.

Aerodynamics

The different shapes and designs of modern planes are a result of innovative solutions that benefit fuel efficiency and the overall performance of avión. Some examples of new aerodynamic design include blended wing body and morphing wings, which can change shape during flight depending on the flight conditions.

Energy Recovery Systems

Nothing promotes efficiency developments in the Aerospace industry like innovative energy recovery systems, which allow planes to recover energy during low-energy periods. Regenerative braking systems, for example, will recover energy during deceleration and can be implemented back into power auxiliary systems or to recharge batteries. Advanced thermal management can also be used to control heat to optimize performance and energy efficiency.

Fuel Efficiency

A major focus in the Aerospace industry is the advancements in fuel efficiency, to limit carbon emissions and make flights as efficient as possible. The demands for net-zero carbon emissions, as well as high fuel and aircraft repair costs bring this issue to the top of the priority list for this industry.

Many of the changes in the Aerospace industry are leading to more fuel-efficient aircraft. Experimenting with these and other advancements such as enhanced propulsion systems, sustainable aviation fuels (SAF) and more will only help increase the efficiency of aircraft manufacturing and flight going forward.

The Innovative Ways That Our Efficient Manufacturing Supports Aerospace

Central Wire Group of Companies is proud to be able to support mission critical Aerospace applications with products that help maximize manufacturing efficiency. Our custom manufactured mil-spec products meet the tight tolerances required to provide efficient performance in this industry. Our Aerospace product lineup includes:

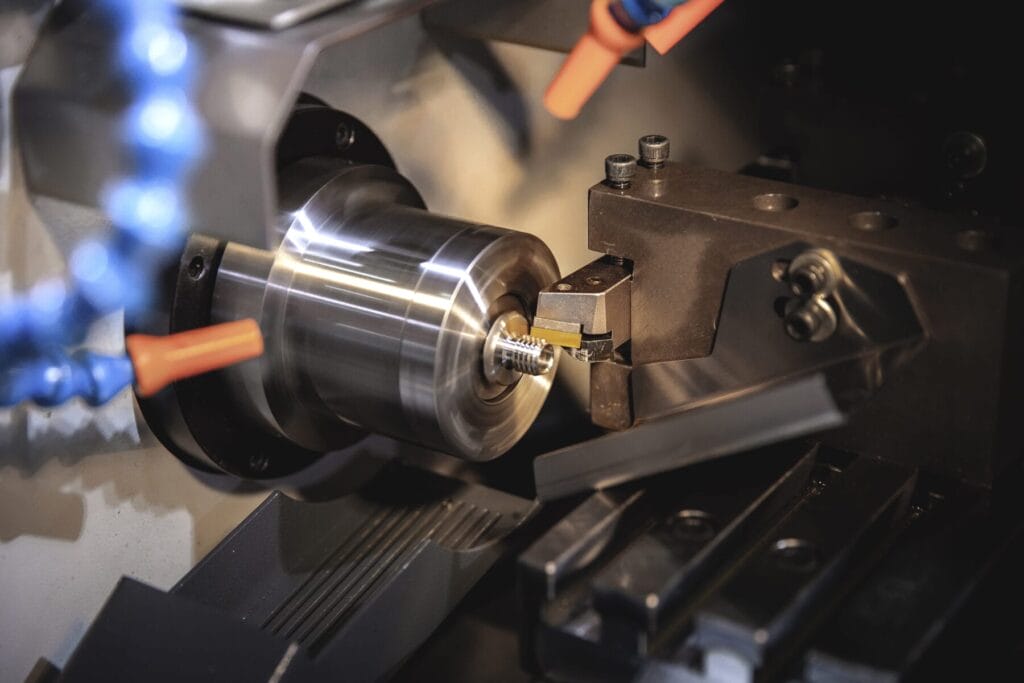

Custom CNC Machined Parts

Aerospace manufacturing requires precision parts, customized to exact dimensions and tight tolerances as small as .0001”. Our wide array of CNC Machines, from Milling machines to Turning machines and more, allow for fast lead times that support the urgent efficiency requirements of mission critical Aerospace applications.

To ensure the quality this industry needs, our CNC products also go through rigorous testing methods to detect any flaws that could affect industry performance.

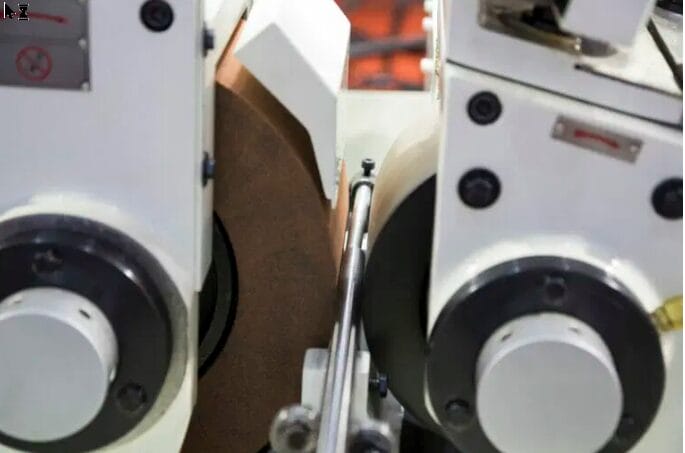

Specialty Bar Stock

Similar to our CNC products, our specialty Bar Stock products provide excellent customization capabilities. Custom produced at our AS9100 certified Perris, California location, our bars are manufactured up to 0.750 inches to our customer specifications.

Central Wire is a global leader in specialty Bar Stock manufacturing, and our Centerless Grinding process gives us the precision to meet tight tolerances and offer improved surface finish.

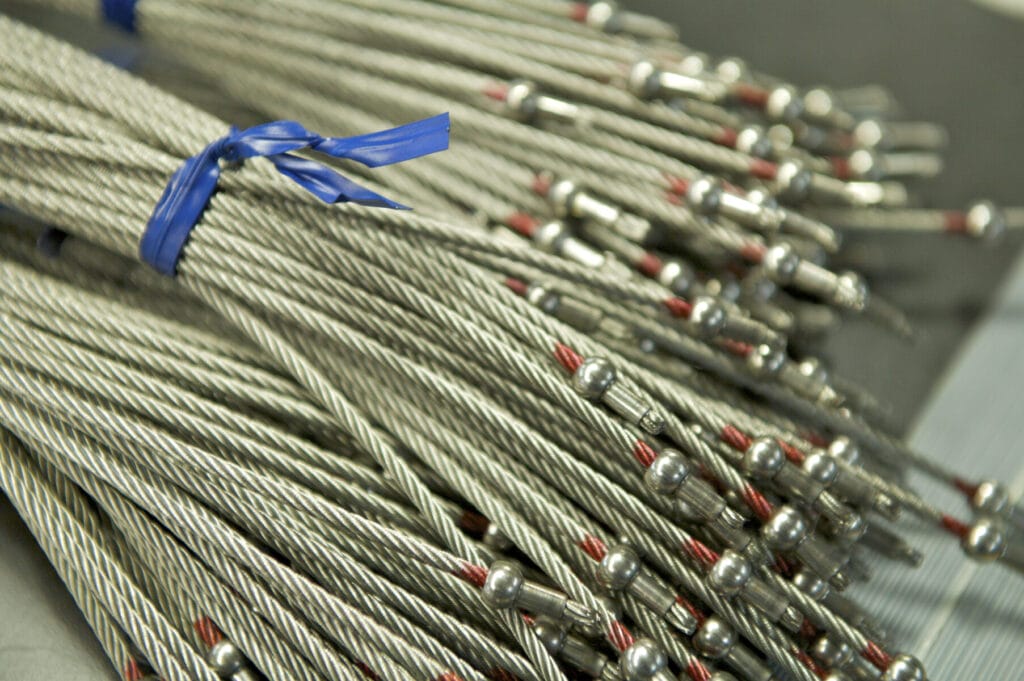

Aircraft Control Cable Assemblies

Efficiency and precision are at the forefront of our Aircraft Control Cable Assembly manufacturing process. With the industry’s largest Assembly inventory, we are able to shorten lead times and offer precision manufactured quality for mission critical applications in a timely manner.

Our start to finish quality control is second to none, as we manufacture the Cable and Hardware used to create our custom Cable Assemblies. With Loos, there is no need to sacrifice quality to invest in Cable Assemblies that are custom manufactured efficiently to your exact specifications.

Choosing Aerospace Quality That You Can Trust

Central Wire Group of Companies is proud to support efficient and effective Aerospace manufacturing with custom products that meet precise customer specifications. Our CNC Machining, Bar Stock manufacturing and custom Cable Assembly capabilities are trusted by many of the industry’s largest corporations.

To improve your Aerospace efficiencies and keep up with the constant technological advances of this industry, Request a Quote today and kickstart your next Aerospace project with us!