Bringing your ideas to life through precision machining, quality materials and rigorous testing methods is what makes our CNC product line the industry standard. With years of experience in custom part manufacturing, our expertise helps support your business’ bottom line with reliable lead times and high quality

For mission critical and commercial components that meet industry standards, offer long-lasting performance and bring your projects to life, our CNC product line is the right answer every time.

Explore our full capabilities below from precision Milling and Turning to rigorous quality testing which detects any defects before delivery.

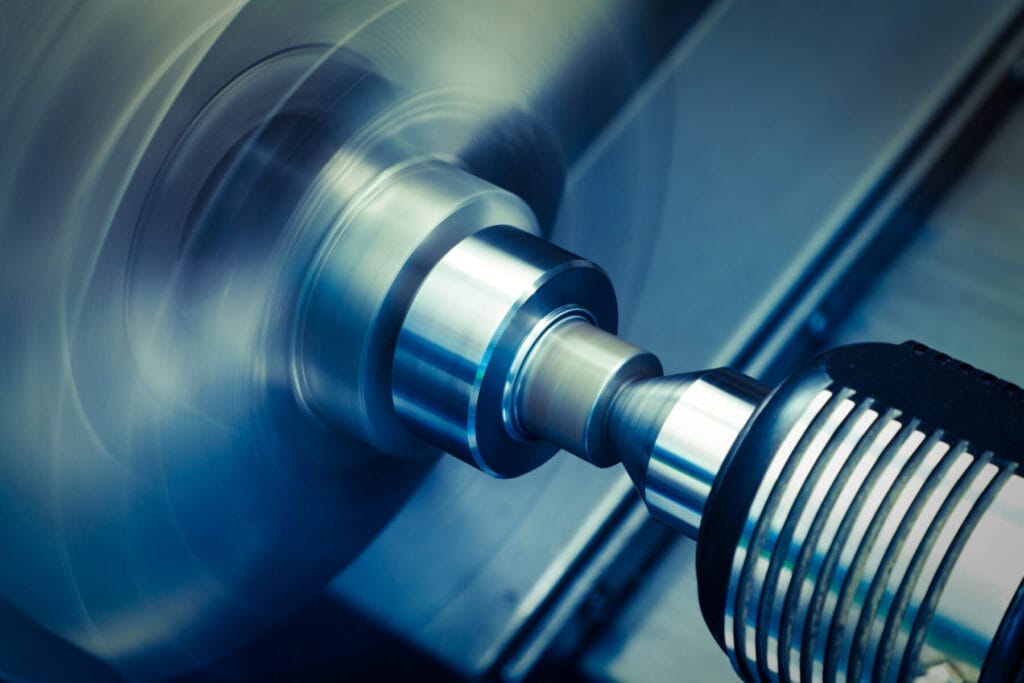

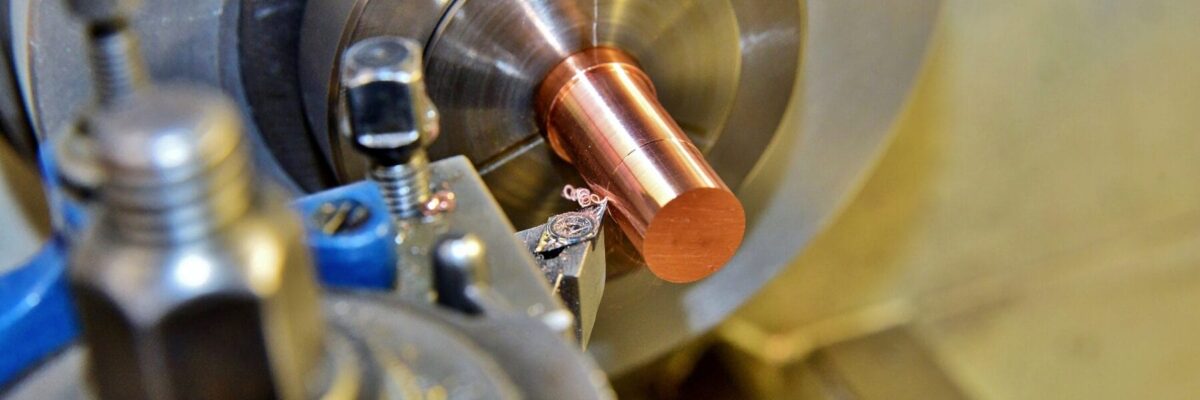

Milling and Turning – From Design to Delivery

Our varied CNC machining capabilities include precision Milling and Turning. With the best equipment in the industry, we can put your ideas into motion from design to delivery. This method of subtractive manufacturing minimizes waste, cutting away from one solid piece of material to create the perfect component for your project.

Our CNC process uses computer aided design (CAD) and computer aided manufacturing (CAM) files to create a set of coordinates, which create a product fit to your exact size requirements. Our machines, including our Milling and Turning machines take it from there, using exact voltage and cutting speed to ensure quality control and accuracy.

The advantages of our CNC Milling and Turning capabilities are endless, with full customization to meet your custom component needs.

CNC Milling:

- High accuracy

- 3 and 4-axis precision Milling

- Versatile machining serving a variety of applications

CNC Turning:

- Precision Turning

- Concentric Turning

- Multi-axis CNC Turning

- Multi-spindle CNC Turning

- Turning with live tooling

Along with these industry leading Milling and Turning capabilities, our efficient CNC machine lineup includes:

- Swiss Lathes

- Hydraulic Presses

- Drill Units

- Grinders

Tight Tolerances That Meet Your Needs

To ensure your precision products meet your exact project requirements, we are able to meet and maintain extremely tight tolerances with our CNC manufacturing. As a trusted leader in Mil-Spec component manufacturing, we supply parts to major distributors and industry leaders around the globe.

With additional capabilities including prototyping or bulk orders, annealing and bead blasting, we truly are the global leaders for CNC Machining. Alongside our knowledge and material variety, we boast the ability to meet tolerances as small as .0001”, meaning no custom material project is out of our wheelhouse.

Our precision machining capabilities are relied on for mission critical applications in both the Aerospace and Military & Defense industries. Common critical applications of our CNC Machined parts include fasteners, engine components, landing gear and other connective aircraft components. Aerospace manufacturers around the world rely on the efficiency and quality produced in our state-of-the-art AS9100 certified facility.

More Than Manufacturing – Our Quality Testing and Inspection Procedures

Alongside an industry leading material inventory and unmatched machine capabilities, our quality testing procedures help to detect critical defects which would impact durability and performance. With modern manufacturing having high stakes and low margins for error, our testing methods aren’t just beneficial – they’re essential.

We use a variety of destructive and non-destructive testing methods to ensure the quality, durability and performance of our products. As more than just a manufacturer, we use methods such as Fluorescent Penetrant Inspection (FPI) to deliver critical quality in our finished products.

FPI is a critical non-destructive testing procedure which detects flaws and defects that would otherwise go unseen. The process involves a fluorescent chemical being applied to a product’s surface, before an Ultraviolet (UV) light is shone on the product. The solution creates a contrast between the smooth surface of the product and any imperfections.

Take a deep dive into the advantages of FPI and other non-destructive testing methods, as well as the full step-by-step process that ensures product quality in our blog on the subject here!

How Our Custom Component Manufacturing Can Support Your Next Project

Loos and Company’s CNC machining capabilities and expertise make us a globally trusted industry leader in custom component manufacturing. With quality materials and testing procedures we are able to deliver precisely what you need, every time.

Our custom CNC parts serve various mission critical and commercial industries with long-lasting performance, including:

- Aeroespacial

- Automoción

- Industrial

- Médico

- Military & Defense

For more information on how we can support your business throughout your whole project, with custom machining and engineering, visit our CNC product page below!