Some products become familiar because of how widely they’re used. Others become familiar because of how consistently they perform. For Loos & Company, the familiarity customers have with our Cable and Wire Rope often begins in one industry, then expands as they discover just how many environments those same products are engineered to serve.

That’s the story behind Cable recubierto y Wire Rope/Strand — two product families widely known, but even more widely capable. Customers recognize the names. They trust the quality. But the range, customization, and multi-industry flexibility often comes as a surprise.

This month’s theme of Familiarity highlights exactly that: familiar products, broader applications, and performance that extends far beyond expectations.

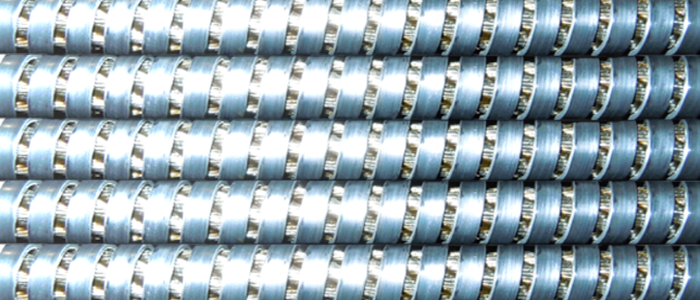

Coated Cable: Familiar Protection, Unfamiliar Range

Most people first discover our Coated Cable through EXERFLEXPRO® — the fitness cable trusted in gyms, training facilities, and high-cycle exercise equipment around the world. It’s become so recognized that many assume “fitness cable” is the beginning and end of what we produce.

But Coated Cable is one of the most versatile product families Loos & Company manufactures. The familiar durability customers see in EXERFLEXPRO® is the same durability that powers our Marine, Industrial, Safety, and Oceanographic lines.

Coated Cable adapts to environments where uncoated cable simply can’t endure. Different coatings are engineered to deliver protection, friction control, visibility, or environmental resistance.

The coatings that move beyond the familiar:

- Vinyl (PVC): Smooth, economical, and flexible; ideal for fitness, safety lines, and recreational equipment.

- Nylon: High abrasion resistance and increased toughness for pulleys and mechanical systems.

- Polyethylene: UV and chemical resistance for long-term outdoor installations.

- Custom blends: Designed for high-wear, high-impact, or highly corrosive environments.

Customers know us for Coated Cable — but most don’t realize they can specify custom diameters, colors, coatings, constructions, and cut lengths to match unique applications.

Kobra Koil™:

Retractable, memory-resistant, perfect for equipment where return force and compact storage matter.

Oceanographic & Armored Coated Cables:

Built for subsea research, harsh marine environments, and mission-critical performance underwater.

If you know Loos & Company for one type of Coated Cable, you already know the quality behind all of them — even if the applications look nothing alike.

Wire Rope & Strand: Better Known Than You Think

“Aircraft Cable” is one of the most familiar terms associated with Loos & Company. And for good reason — our Aircraft Cable is trusted worldwide for its precision, fatigue life, consistency, and strict adherence to specification.

But the familiarity that comes from aviation often hides the full breadth of what Wire Rope and Strand really do. Many customers are surprised to learn that our cable is powering:

- Construction hoists

- High-rise elevators

- Marine rigging and winches

- Industrial automation systems

- Safety rails, fall protection, and architectural supports

The same strength and fatigue resistance that makes Aircraft Cable reliable in a cockpit makes Wire Rope reliable in a crane. The same strand uniformity that makes it safe for flight also makes it safe for marine lifts or load-bearing industrial motion systems.

Familiarity with Aircraft Cable simply opens the door to understanding the larger range.

Strength Beyond Aviation

Wire Rope is engineered with precision at every stage:

- Tight tolerance control during wire drawing

- Consistent tensile properties across all strands

- Verified mechanical performance for fatigue-critical applications

- Surface finishes and lubricants matched to real-world wear patterns

The aircraft-grade consistency customers trust in one industry is the same consistency applied across the entire Wire Rope lineup — even for applications they never knew used the product.

Familiar Engineering, Expanded Capability

A customer might experience Coated Cable in a fitness facility but never imagine that the same manufacturing team produces custom subsea cables engineered for saltwater survival.

They might know Wire Rope for flight control systems but never consider that the identical engineering discipline is behind architectural tension structures or industrial conveyor systems.

That’s the power of familiarity: The quality you already recognize appears in places you didn’t expect.

Loos & Company’s cable products earn their familiarity not through marketing, but through repeatable, predictable performance across decades and industries.

Why Familiar Products Create Unfamiliar Opportunities

When customers trust a product family, it becomes easier to adopt it across new applications. That’s why familiarity is a competitive advantage — it shows customers exactly where else their trusted products can solve problems.

Our Coated Cable, for example, bridges from fitness equipment to:

- perimeter security systems

- marine mooring lines

- industrial limit switches

- overhead doors

- sprinkler restraint systems

Wire Rope bridges from aircraft control systems to:

- stage rigging

- lifting assemblies

- robotic automation

- construction hoists

- marine vessels and deck systems

Each new application feels familiar because:

The engineering requirements — strength, fatigue life, protection, dimensional integrity — remain the same.

Once customers understand that, they begin to use our products in new industries with confidence.

Global Consistency Strengthens Familiarity

Knowing a product is consistent builds familiarity. Seeing that consistency replicated worldwide builds trust.

With manufacturing across the US, Canada, and the UK, Loos & Company maintains unified standards for:

- mechanical properties

- coating specifications

- strand uniformity

- construction control

- inspection and documentation

- coil-to-coil consistency

Whether a customer buys Coated Cable for fitness equipment or Wire Rope for a marine lift, the quality story is unmistakably the same.

Familiar Products, Broader Impact

Coated Cable and Wire Rope may be familiar, but their capabilities extend far beyond the surfaces where most customers first encounter them. The same materials, processes, testing, and engineering principles that build their reputation in one sector allow these products to deliver value in many more.

Next Steps

Explore our Cable recubierto y Wire Rope to see how Central Wire delivers accountability through testing, certifications, and products built to last.

For project guidance or to request a quote, contact our team today at sales@loosco.com