When choosing a manufacturer for Knitted Wire Mesh products, there are many factors to consider. If you already have a supplier that you trust, it can be difficult to decide to switch to somebody new.

At Central Wire, we have the combination of industry expertise and custom manufacturing capabilities that set us apart from the rest. Our products are tested to ensure the quality is up to the standard our customers expect, and that end-use performance is consistent and reliable.

Nuestra Tech-Mesh products serve countless industries from Oil and Gas to Mining to the Renewable Energy sector. Handling the material challenges of these industries requires years of manufacturing experience and knowledge.

Continue reading to discover the 7 differentiators that set us apart in the industry and make CWI the right choice for your next Knitted Mesh project.

Vertical Integration

A major component of our Custom Demister Pad manufacturing is the vertical integration involved in the process. The best way to make sure the materials used are reliable is to use our own.

Our Demister Pads are made using our own Fine Wire, Welding Wire, y Round Bar Stock produced in-house. By doing this, we ensure complete quality control from start to finish. The various testing and quality assurance processes done on these product lines lead to the durability and reliability our customers expect.

In-House Expertise and Capabilities

We pride ourselves on being both industry leaders and industry experts when it comes to our Tech-Mesh™. The research that goes into this product line allows us to keep up with modern industry challenges and adapt to serve our customers better.

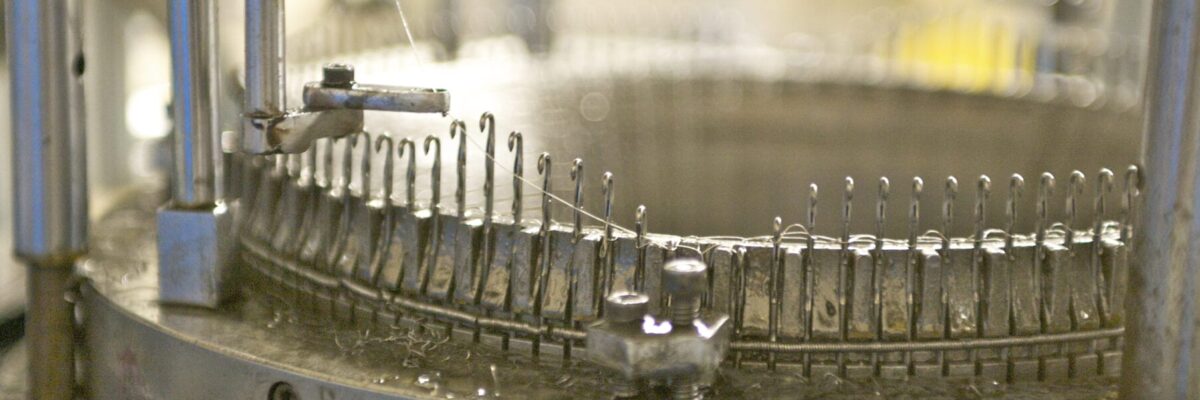

Our custom-built in-house equipment also sets us apart. Our knitting equipment is built internally, giving us the precision to meet your specific project needs. In addition to building our knitters in-house, we have now also made crimpers in-house. The pleat or wave in the mesh is the result of crimping and it makes the finished product perform as needed.

Quality Management System (QMS)

Our robust QMS ensures that every product meets the highest standards. We are able to conduct both destructive and non-destructive testing to confirm that our products can stand up to harsh industry conditions.

Our product testing capabilities include Tensile Testing, Cold Bend Testing, Resistance Testing and Fluorescent Penetrant Testing (FPI). con

To learn more about our quality management and testing capabilities, visit our website here.

Leading Manufacturer

Our manufacturing capabilities stand above the rest, giving us the capabilities to manufacture to the various product lines and industries we serve.

We are the largest Stainless Steel, Nickel, and Copper-Based Alloy wire manufacturer in North America. Not only is the list of our locations and industries served vast, but we have the custom manufacturing capabilities to accommodate a variety of projects.

If you have any questions about our capabilities as a manufacturer, and what projects our Tech-Mesh™ products can be used in, visit our product page here.

Fast Turnarounds

We know how urgent some projects can be, and how important quick lead times and turnarounds can be to keeping operations running smoothly. At CWI, our streamlined processes lead to quick lead times, helping to maximize project efficiency for our customers.

With multiple locations and large, knowledgeable manufacturing teams, we can get you the right product while limiting the downtime on your project. We also have great machining capabilities, as our knitting machines can knit 2-3x faster than our competitors.

Specialty Alloys

At CWI, we know that not every project is the same. The various demands of the industries and applications our Tech-Mesh™ products serve calls for a wide selection of unique material options.

Our entire Tech-Mesh™ product line has Stainless Steel, Copper and Specialty Alloy options available to handle the harsh conditions present in the Oil and Gas, Mining, Petrochemical, and Environmental Industries.

Technical Support

At Central Wire, we are not just manufacturers. Our knowledgeable team includes metallurgists and technical support team members who are able and available to help you with any technical challenges, as well as product recommendations.

For any questions about the specific product, material or size you require for your next project, don’t hesitate to reach out to us at sales@centralwire.com!

Choosing CWI

Our knowledge and manufacturing capabilities make us the right choice for your next project. Additionally, all our orders are custom fabricated to your exact specifications, ensuring the best fit for your application. We don’t stock standard Demisters to the wide variety of sizes, alloys and mesh types we have available.

Whether you’re troubleshooting an existing application or sizing a new one, our team is ready to help optimize performance. Choosing CWI Tech-Mesh™ means selecting a partner committed to quality, innovation, and customer success.

If you’re ready to kickstart your next Mesh product with CWI, Request a Quote with us today!