Meticulous Manufacturing Processes Offering our Customers Unmatched Product Quality

CWI in-house technical staff can perform a wide range of services which include PPAP preparation and submissions, a recommendation for application requirements, process improvement, metallurgical analysis, and root cause identification process. The technical services team is staffed by metallurgists and technologists proficient in not only the product, but the full range of applications for each product.

Our versatility as a manufacturer stems from our machine capabilities, years of expertise, and premium raw materials.

Learn how we manufacture to the exact specifications of your project, and meet tight tolerances below:

Rod Processing

Rod Breakdown

Annealing

When the wire is drawn, it builds up strength due to work hardening. Time at temperature “softens” the wire and allows for continued processing or increased ductility or varied electrical properties in specific applications.

Stress Relieving

Particular wire alloys can be strengthened by “soaking” in a low-temperature bath. Also useful in strand and cable products where mechanical processes do not straighten effectively.

Dry Drawing

Processing wire in a dry lubricant to reach a desired diameter and tensile strength. Most common in larger diameters (above .040”) where surface area reductions are low and heat dissipation is not a primary concern. Creates a matte appearance of the surface finish which can be desirable for some aesthetic applications.

Wet Drawing

Processing wire in a liquid lubricant can be water or petroleum-based. Most common in smaller diameters where heat and penetration of the dies becomes a concern. Produces a shiny, smooth surface finish that is desirable in many applications — used primarily in finished diameters below .040”.

Fine Wire Drawing

High-speed drawing of wire for critical applications with diameters in the 0.005” to 0.010” range requires specialized dies and drawing fluids to maximize strength and surface finish.

Cleaning

Aqueous acid wash or hot alkaline baths remove wire drawing lubricants to offer a cleaner material that extends furnace and lubricant life in downstream processing. Finished products are shipped that eliminate the need for additional cleaning before installation or further processing.

Coating

Wire is given a lubricating or preservative coating to assist with longevity or additional processing.

Straighten and Cut

Coil product is converted to cut lengths as straightened bar stock. The straighten and cut bars are used in grinding, machining, shaping, and forming processes.

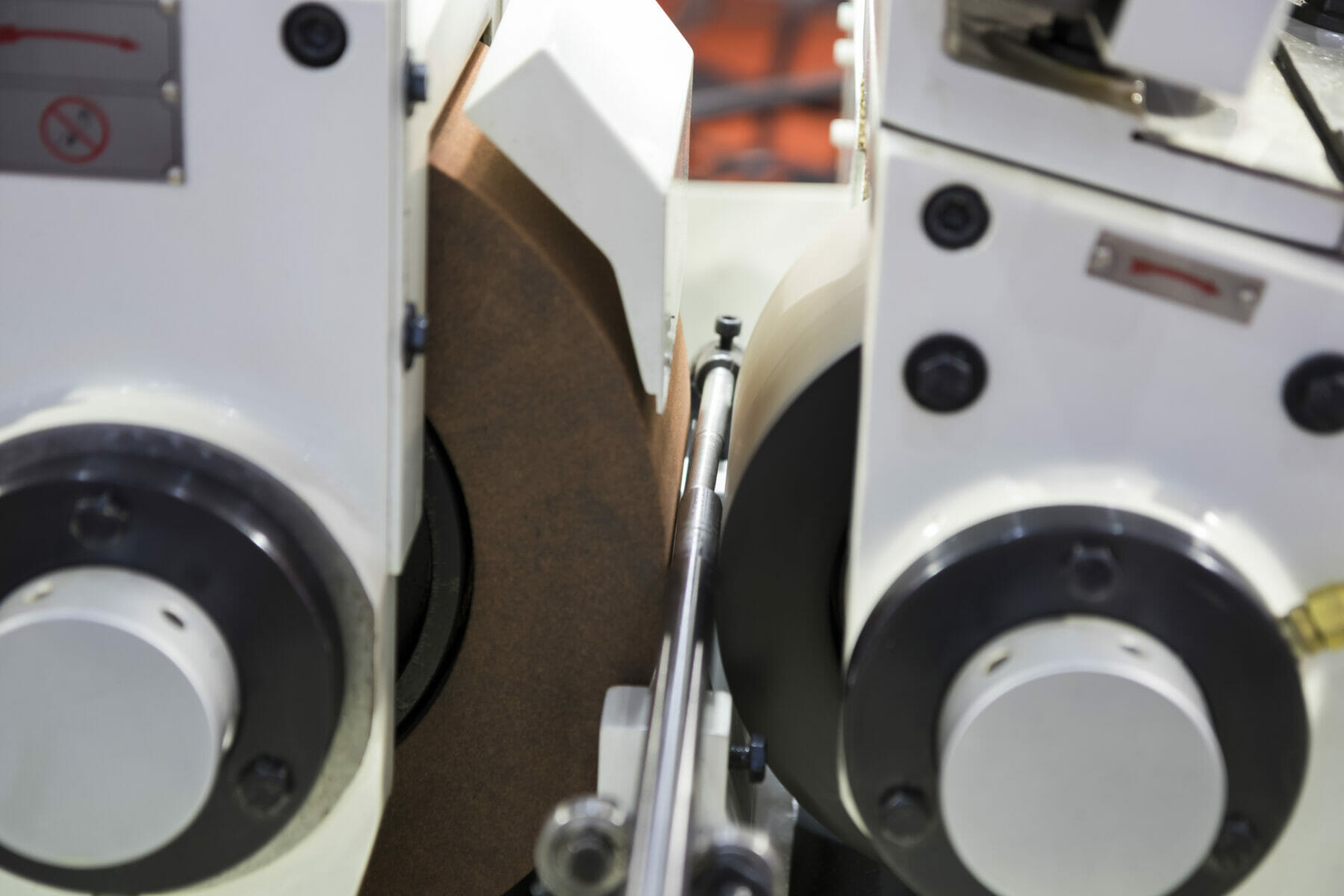

Center-less Grinding

The through-feed center-less grinding process ensures high productivity up to .760”. The workpiece is fed through the grinding wheels completely, entering on one side and exiting on the opposite side. Material is bundled by individual lot to ensure full traceability back to the mill source.

Test e ispezioni

Strength, hardness, yield, conductivity, surface finish, and more are tested at various steps during the process to confirm 100% compliance with all specifications.

Spooling & Packaging