Quality Food Processing and Beverage Filtration

The food processing and beverage industries offer many challenges, from requiring antibacterial metals to withstanding temperature changes. Consistent products ensure quality food and beverage production.

Below you can see our products lines that cater to the industry, and the applications of our products to the food processing and beverage industry.

Linee di prodotto

Manufactured with Lolon® coatings setting the standard for durability and reliability in the conveyor industry. High quality conveyer cables ensuring minimal downtime and maximum efficiency.

CWI red metals are available in a variety of high-performance alloys. Copper’s conductivity and antibacterial properties make it applicable for resistance wire, fine wire, knitted mesh and medical wire applications.

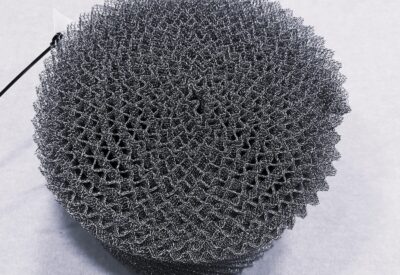

Custom demister pads manufactured in shapes including round, rectangle, ring and custom. Strong grid structure and ductility capabilities allow for consistent mist elimination.

Wire filter mesh made from individual wires that are interlaced, or knitted, together. Loops are strategically woven to be able to move and stretch, with flexibility and durability to handle harsh applications.

Resistance wire is designed specifically for high temperature applications, offering resistance tolerances per the American Wire Gauge. Available in sizes from 0.001” to 0.0808” with tempers ranging from annealed to full hard.

Available in stainless, duplex, nickel, copper, brass and carbon alloys, our shape wire is custom manufactured in house to fit specific customer needs. The profile wire sizes we offer are 1.25mm² to 150mm ² CSA (Cross Sectional Area).

Filo per saldatura produced per varie tecniche, tra cui la saldatura MIG, TIG e SAW. Disponibile in leghe inossidabili e a base di nichel.

From filtering, to heating and cooling, to conveyor belts in food processing plants, our product serves this industry in various ways. Our quality materials ensure quality food processing and beverage filtration, while supporting the ease of production.

Here are some of the ways our products are used in food processing and beverage applications.

Applicazioni del prodotto

Brewing & Distilling

Our Tech-Mesh™ product line support the filtration process involved in both brewing and distilling beers and spirits. Typically, copper mesh is used in distilling to disinfect and purify spirits, while steel is preferred for the filtration of beer.

Quality filtration can ensure no unwanted compounds can sneak through our mesh and demister pads, preventing undesirable flavors. Clarity, shelf life and consistency are also affected by poor filtration materials, so choosing quality product is crucial.

Conveyor Belts

A crucial part of the food processing industry is conveyer belts, which maximize efficiency and reduce physical labor in manufacturing.

Our galvanized cables with Lolon® coatings ensure excellence and durability in this application, avoiding any malfunctions that delay production.

Vessel Repairs

A big part of all industries is limiting repairs and downtime where manufacturing and production can’t be done. In brewing and distilling, large vessels are often used to store both liquids.

To ensure quality, specific temperatures and conditions are required in these vessels. Strong welds ensure that when manufacturing these vessels, repair requirements will be limited. When repairs are required, the right welding technique ensures they last.

Temperature Control

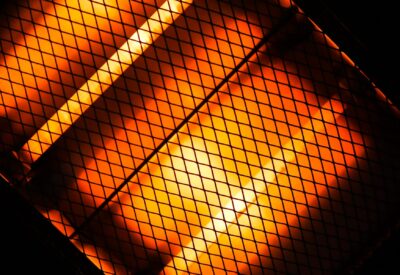

In both food and beverage applications, temperature control is crucial to mantenimento quality of products. Boilers, kettles and stills require resistance wire to hear water, wort (unfermented beer), or distillation liquid for various processes like mashing, boiling or distillation.

In terms of food processing, resistance wire can be used for any products that require cooking, baking, or mantenimento a certain temperature before it is moved out to restaurants or stores.